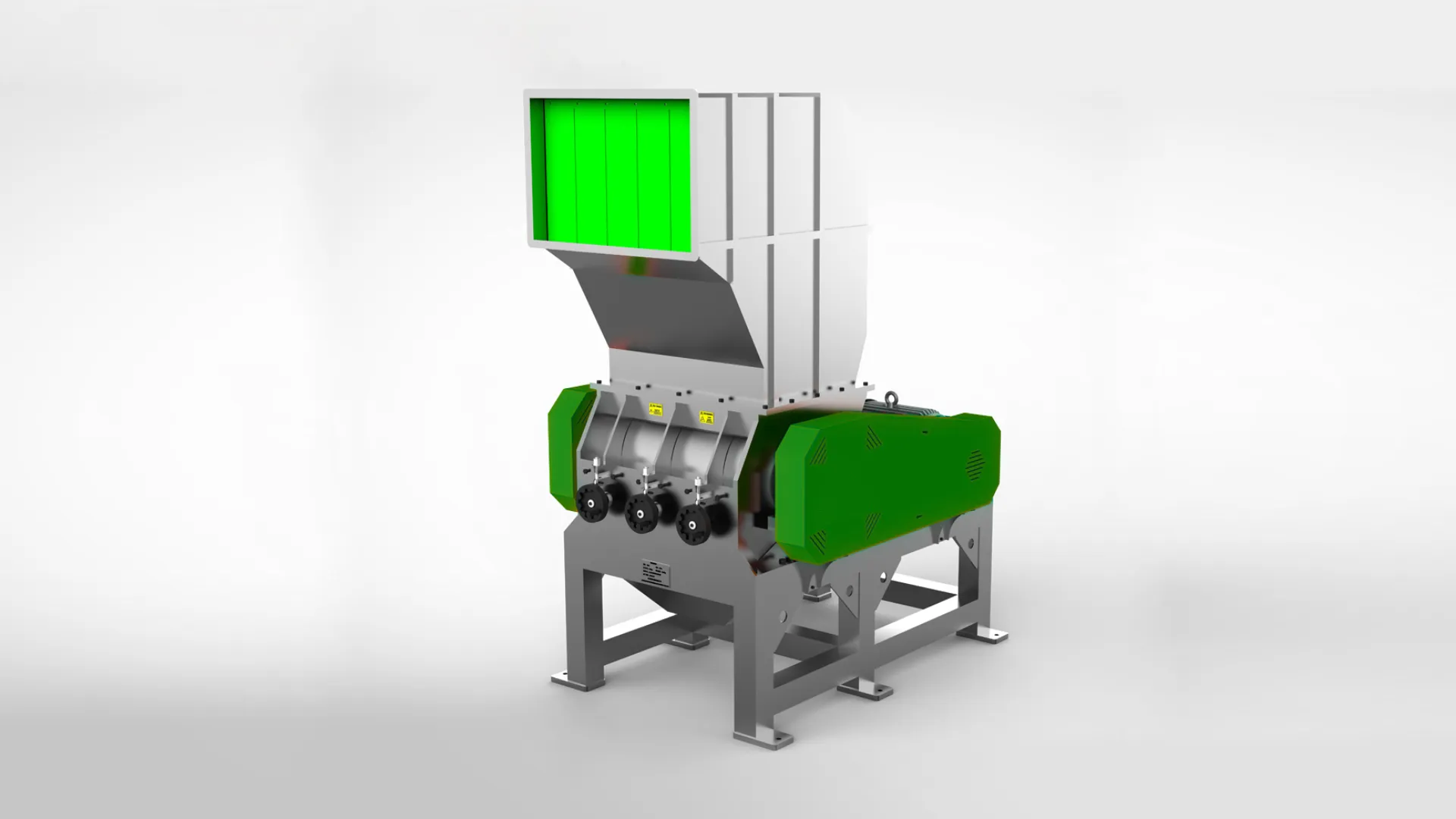

Standard Plastic Granulator

Efficient, reliable, and essential machinery for the plastic recycling industry. Transform plastic waste into valuable resources with Rumtoo Machine.

Get a Quote

Efficient Processing

Quickly and effectively crushes various plastic products into uniform small particles, ready for the next stage of recycling.

Reliable & Safe

Built with high-carbon, high-chromium steel blades and trusted components from Siemens and Schneider for maximum durability and operator safety.

Sustainable Solution

Minimize environmental pollution and reduce waste disposal costs by turning plastic waste into a reusable commodity.

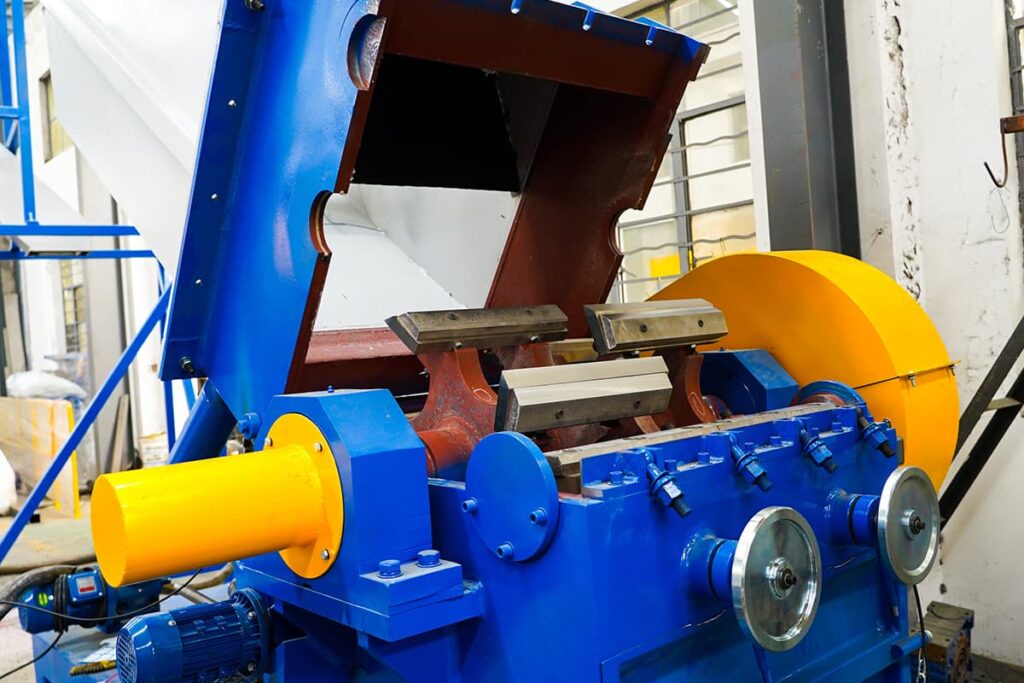

Advanced Cutting Technology

Our plastic granulator operates with an open rotor and heavy-duty knives in a v-shape or double-scissor array, ensuring a clean and consistent cut.

How It Works

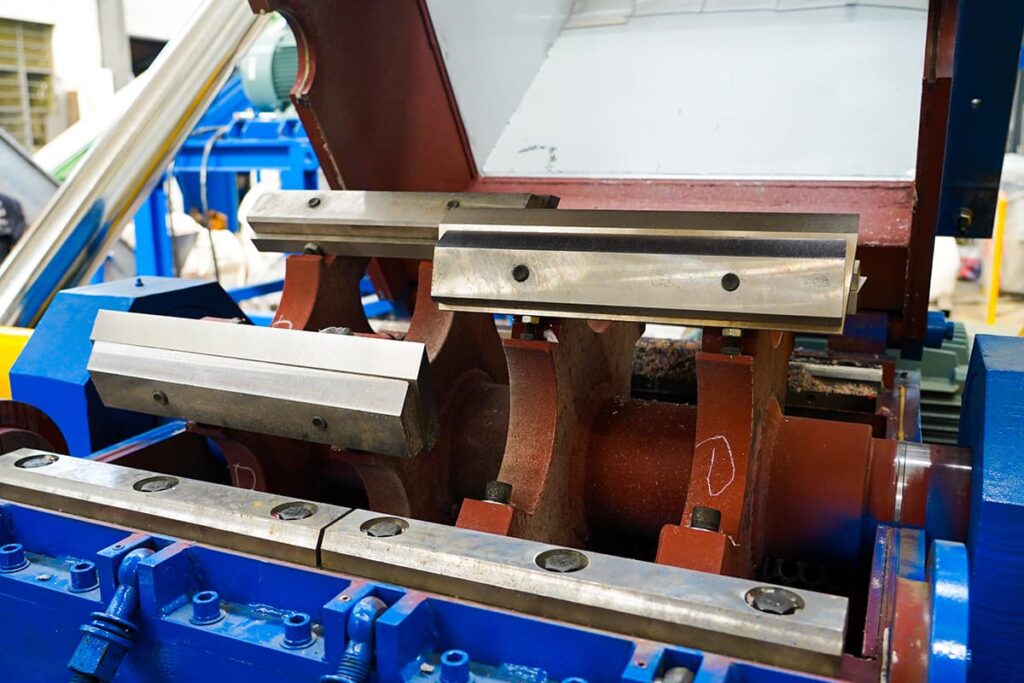

As the rotor spins at high speeds, its knives come into contact with stationary knives mounted within the cutting chamber. The material is continuously cut until it is small enough to pass through a screen filter. Our filter screens are customizable from 10mm to 100mm to meet your specific requirements.

Our standard model contains 12 rotor knives and 3 stationary knives, all using ultra-durable D2 high-carbon steel.

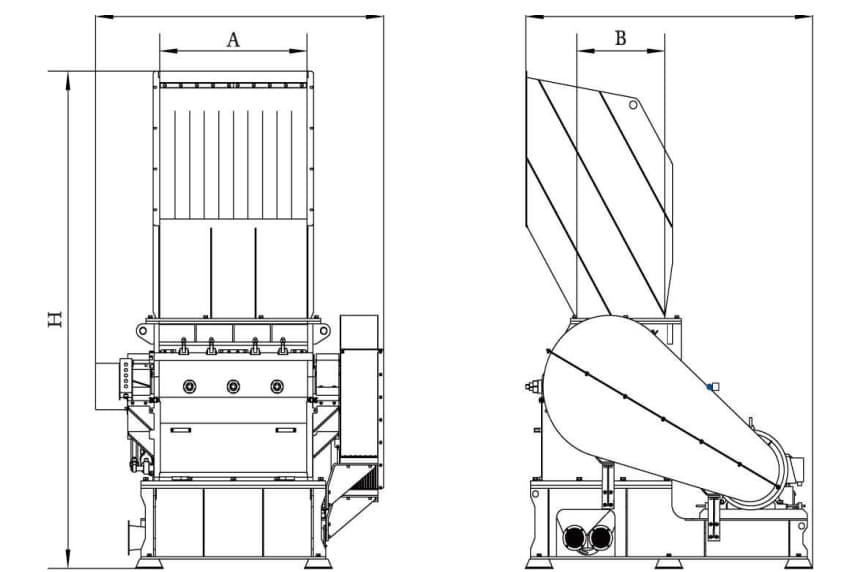

Designed for Performance and Ease of Use

Key Features

- Stepped blade distribution improves cutting force and enhances working efficiency.

- Hydraulically actuated hopper & cradle for easy blade & screen replacement.

- Sound insulation interlace in the feeding mouth to reduce noise levels.

- Main electrical components are trusted brands like Siemens and Schneider.

- Re-sharpenable blades significantly reduce long-term operating costs.

- All machines come with a 1-year limited warranty.

Main Technical Parameters

Find the model that fits your production needs. We can also customize according to your requirements.

| Model | GSH-500 | GSH-600 | GSH-700 | GSH-800 |

|---|---|---|---|---|

| Rotating speed(rpm/min) | 550 | 500 | 428 | 370 |

| Rotary diameter(mm) | Φ500 | Φ600 | Φ700 | Φ800 |

| Main motor power | 45kW | 55kW | 90kW | 110kW |

| Knife material | SKD11 | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 500-800 | 800-1500 | 1500-2000 | 2000-2500 |

Granulators vs. Shredders

Understanding the right tool for the job is crucial. Here’s a quick comparison.

Plastic Granulators

Ideal for processing smaller or pre-shredded plastic waste like bottles, films, and small hard plastics. They use high-speed cutting to produce small, uniform particles (granulate) ready for manufacturing.

Primary Use: Secondary size reduction, creating final product.

Plastic Shredders

Primarily used for breaking down large, bulky plastic items such as drums, pipes, and car bumpers. They use high torque and low speed to tear material into smaller, rough-cut pieces.

Primary Use: Initial, primary size reduction.

Explore the Machine

Frequently Asked Questions

1. What is the difference between a plastic granulator and a shredder?

A plastic granulator uses high-speed rotating knives to cut plastic waste into small, uniform particles (regrind), ideal for direct reuse in manufacturing. A shredder uses high-torque, low-speed blades to tear large, bulky items into smaller, rough pieces for primary size reduction or disposal.

2. What types of plastic can the Rumtoo granulator handle?

Our standard granulator is highly versatile and can efficiently process a wide range of materials, including PET bottles, HDPE containers, plastic films, PVC pipes, and various other hard and soft plastic scraps. We can also customize the machine for your specific material needs.

3. Why are D2 steel blades important for a plastic crusher?

D2 steel is a high-carbon, high-chromium tool steel known for its excellent wear resistance and durability. Using D2 steel blades means they stay sharp longer, require less frequent sharpening, and can withstand the impact of tough materials, significantly reducing maintenance downtime and long-term operating costs.

4. How can I get a price for your plastic granulator?

Pricing depends on the specific model, motor size, and any custom requirements you may have. For an accurate and competitive quote, please use the inquiry form below on this page. Our team will contact you promptly with detailed pricing and lead time information.

5. What kind of warranty comes with your machines?

All Rumtoo Machine recycling equipment, including our standard plastic granulator, comes with a comprehensive 1-year limited warranty. This covers any defects in materials and workmanship, ensuring your investment is protected.

Ready to Boost Your Recycling Efficiency?

To get the latest prices and lead times, send us a message using the form below. Our team will get back to you shortly.

Comments are closed.