Everything needed for

modern recycling.

Comprehensive solutions designed to handle the toughest plastic waste with ease.

Tailored Solutions.

Our pre-sales team provides free design services to optimize the line for your specific factory layout and material needs.

Precision Engineering.

Advanced CNC machining and strict quality control ensure every screw, tank, and dryer meets the highest standards.

Smart Operation.

Intuitive controls and comprehensive operation guides make running your plant effortless.

24/7 Support.

Always-on customer service to answer questions and solve issues remotely or on-site.

Global Reach.

Serving 1200+ happy clients worldwide with reliable shipping and installation.

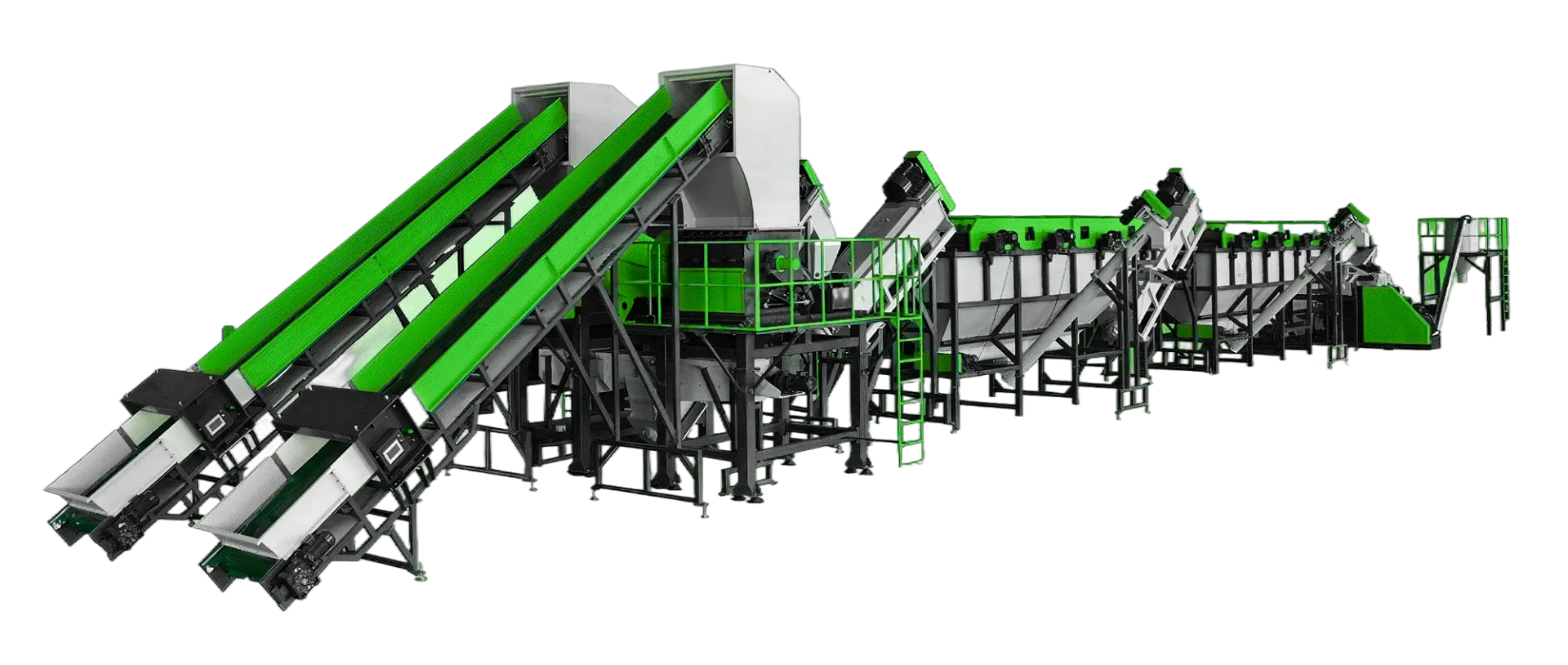

From Waste to Value.

Collection

Sorting & Feeding

Crushing

Size Reduction

Washing

Friction & Floating

Drying

Moisture Control

Pelletizing

Ready for Reuse

See it in Action.

Pro-grade

capability.

Industrial reliability.

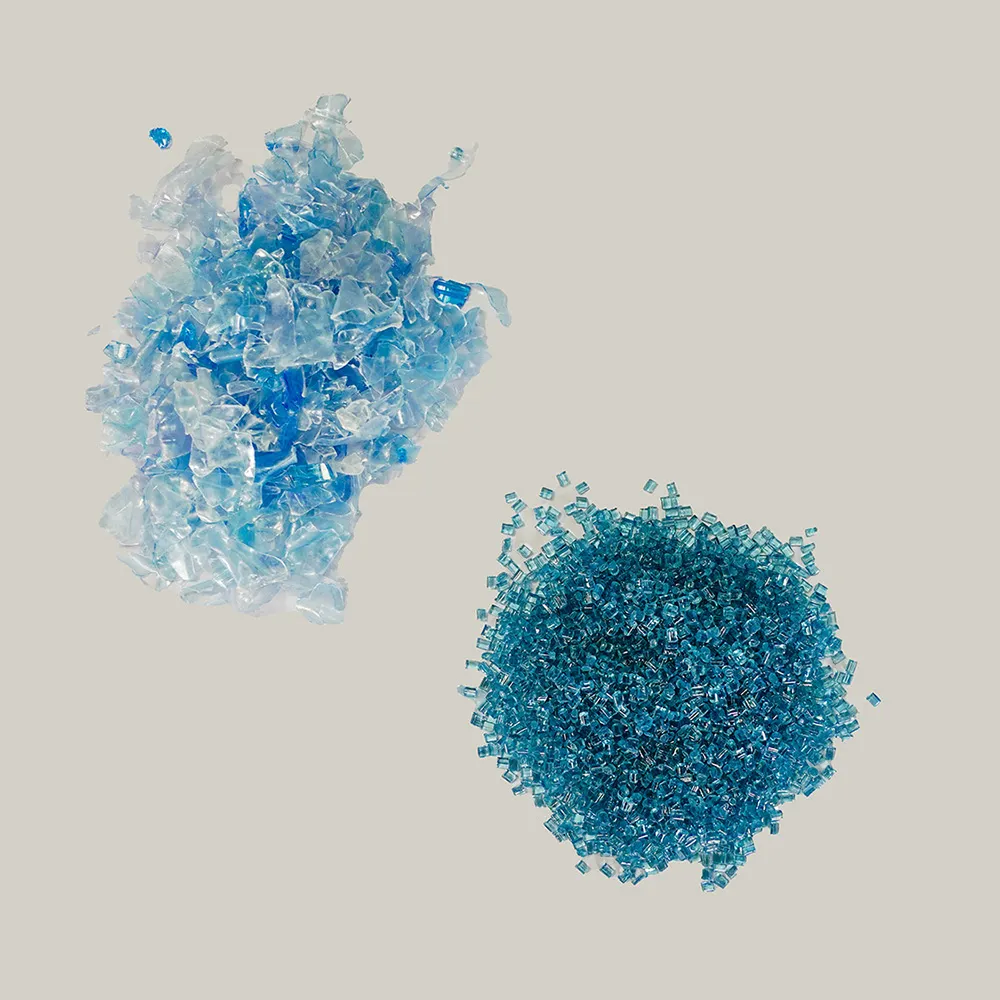

We utilize advanced technology to remove contaminants effectively. Whether it's PET bottles, PE films, or rigid plastics, our washing lines deliver high purity output.

99%

Purity Rate

24/7

Continuous Ops

1200+

Installations

100%

Support

Total Control.

At your fingertips.

Integrated PLC systems with intuitive HMI touchscreens allow for precise monitoring of every stage. Adjust motor speeds, monitor temperatures, and track throughput in real-time.

World-Class Components.

SIEMENS

Motors & PLC Systems

Schneider

Electric Components

SKF

High-load Bearings

ABB

Drives & Inverters

Materials we handle.

Trusted by Industry Leaders.

Technical Specifications View Data

| Capacity (kg/h) | Install Power (kw) | Required Area (m²) | Required Staff | Water (m³/h) |

|---|---|---|---|---|

| 300 | 150 | 350 | 4-5 | 3 |

| 500 | 230 | 460 | 5-6 | 4 |

| 1000 | 430 | 500 | 6-8 | 5 |

Questions you might have.

What materials can your washing line handle?

Our systems are versatile and can handle PET bottles, HDPE milk bottles, PE films, PP woven bags, and rigid plastics like ABS/PS from e-waste. We customize the component configuration based on your specific material.

What capacity options do you offer?

We offer standard lines ranging from 500kg/h to 3000kg/h output capacity. For larger recycling plants, we can engineer custom high-throughput solutions up to 5 tons per hour.

Do you provide installation and training?

Yes, we send experienced engineers to your site for installation, commissioning, and staff training. We also provide lifetime remote technical support and 24/7 online assistance.

How long is the delivery time?

Standard washing lines typically take 60-90 days to manufacture and test. Custom or larger capacity lines may require additional time. We provide a strict project timeline upon order confirmation.