Transform Plastic Waste into Profit

Introducing the Shredding & Densifying Recycling Line: The ultimate solution to reduce volume, cut transportation costs, and create high-value raw material from plastic film waste.

Get A Quick QuoteWhy Choose Our Densifying Line?

Maximum Density

Increase bulk density up to 10x, drastically reducing storage space and handling effort.

Lower Transport Costs

Ship more material in a single load, significantly cutting your logistics expenses.

High-Value Output

Produce a dense, low-moisture (<3%) feedstock perfect for pelletizing or chemical recycling.

Streamlined Operation

An all-in-one, automated system from bale breaking to densified product output.

From Waste to Value in 4 Steps

1. Shredding

Bales of plastic film are broken down into smaller, manageable pieces.

2. Granulating & Washing

Material is cut into flakes while being washed to remove contaminants.

3. Separation

A sink/float tank separates heavier dirt from the lighter plastic flakes.

4. Squeezing & Densifying

Clean flakes are compressed and heated to create dense, dry agglomerates.

Key Components & Technical Data

Heavy-Duty Shredder

Equipped with a movable hopper, it efficiently breaks down compacted film bales for consistent feeding into the line.

Multifunctional Squeezer Dryer

The core of our system. It dewaters, densifies, and compacts the material, reducing moisture from >30% to <3%.

Main Technical Parameters

We offer standard capacities from 200kg/h to 1000kg/h and provide full customization to meet your specific needs.

| Model | RUM-200 | RUM-500 | RUM-1000 |

|---|---|---|---|

| Operation | 2-3 | 2-3 | 2-3 |

| Installation power | 160-200kW | 200-240kW | 400-450kW |

| Knife material | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 200 | 500 | 1000 |

See The Machine In Action

Get Your Custom Solution & Quote

To get the latest prices and lead times, send us a message using the form below. Our experts will contact you within 24 hours.

Frequently Asked Questions

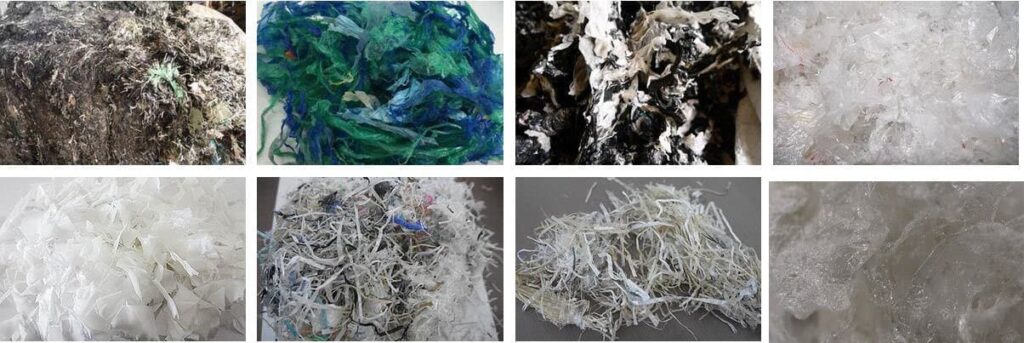

What types of plastic can this line process?

This line is primarily designed for soft plastics like post-consumer or post-industrial PE (Polyethylene) and PP (Polypropylene) films, including packaging films, agricultural films, and woven PP bags.

What is the final moisture content of the output material?

Our specialized squeezer dryer is highly efficient, capable of reducing the material’s moisture content to below 3%, which is ideal for subsequent processing like pelletizing.

What is the bulk density of the densified product?

The process significantly increases the bulk density to approximately 350-410 kg/m³, making the material much more compact for storage and transportation.

Do you offer a warranty?

Yes, all our recycling machines come with a 1-year limited warranty. We are committed to providing reliable, high-performance solutions.