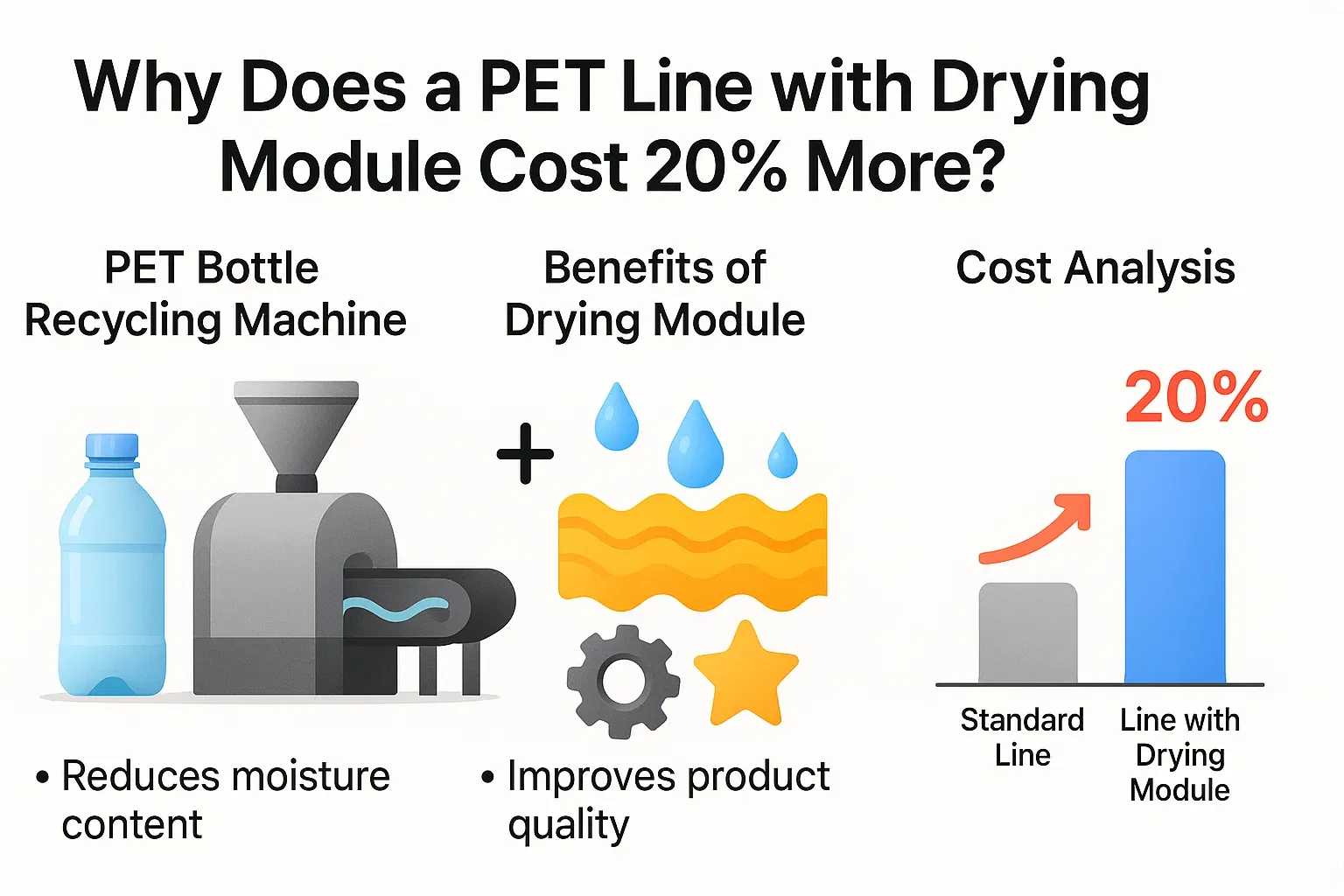

In the world of plastic recycling, investing in the right equipment is critical for achieving high-quality output and operational efficiency. For professionals in the recycling industry, engineers, and industrial equipment buyers, understanding the cost dynamics of a Machine de recyclage de bouteilles PET is essential when selecting the right system. One common question that arises is: Why does a PET line with a drying module cost 20% more? In this article, we’ll break down the factors contributing to this price difference, explore the value a drying module adds, and help you make an informed decision for your recycling operations.

At Rumtoo, we specialise in delivering cutting-edge PET Bottle Recycling Machines designed to meet the demands of modern recycling facilities. Our expertise ensures that every component of our systems, including drying modules, is engineered for performance and reliability. Let’s dive into the reasons behind the cost premium and why it’s often a worthwhile investment.

Qu'est-ce qu'une machine de recyclage de bouteilles PET ?

A Machine de recyclage de bouteilles PET is a sophisticated system designed to process post-consumer polyethylene terephthalate (PET) bottles into clean, reusable flakes or pellets. These machines typically include stages such as sorting, washing, shredding, and drying, with each step optimised to produce high-quality recycled PET (rPET) suitable for applications like food-grade packaging or textiles.

The inclusion of a drying module in a PET line enhances the system’s ability to deliver superior-quality output. However, this additional component often increases the overall cost by approximately 20%. To understand why, let’s explore the role of the drying module and its impact on the recycling process.

The Role of the Drying Module in PET Recycling

A drying module is a critical component in advanced PET Bottle Recycling Machines, designed to remove residual moisture from PET flakes after the washing process. Moisture removal is essential to ensure the quality of the recycled material, as excess water can lead to defects during subsequent processing, such as extrusion or pelletising.

Key Functions of the Drying Module

-

Moisture Reduction: Removes residual water from washed PET flakes to levels below 1%, ensuring the material is suitable for further processing.

-

Improved Material Quality: Prevents hydrolysis (degradation of PET due to moisture) during high-temperature processes like extrusion.

-

Enhanced Efficiency: Reduces energy consumption in downstream processes by delivering dry, ready-to-process flakes.

-

Consistency: Ensures uniform drying, minimising variations in the final product’s quality.

Without a drying module, PET flakes may retain moisture, leading to issues such as inconsistent pellet quality, reduced mechanical properties, or equipment wear. The drying module addresses these challenges, but its inclusion comes with added costs. Let’s examine why.

Why Does a Drying Module Add 20% to the Cost?

The 20% cost increase associated with a PET line equipped with a drying module can be attributed to several factors, each contributing to the system’s overall value and performance.

1. Advanced Engineering and Components

Drying modules are complex systems that incorporate high-performance components, such as:

-

Centrifugal Dryers or Hot Air Systems: These use advanced technology to remove moisture efficiently, requiring robust materials to withstand continuous operation.

-

Precision Controls: Automated systems ensure consistent drying temperatures and airflow, adding to the manufacturing cost.

-

Durable Construction: Components are often made from corrosion-resistant materials like stainless steel to handle wet environments, increasing production costs.

These engineering advancements ensure reliability and longevity but contribute significantly to the upfront cost.

2. Increased Energy Requirements

Drying modules require energy to heat air or power mechanical systems like centrifugal dryers. To optimise energy efficiency, manufacturers like Rumtoo incorporate advanced insulation and energy-recovery systems, which add to the initial investment but reduce long-term operational costs.

3. Integration with the PET Line

Integrating a drying module into a Machine de recyclage de bouteilles PET requires careful design to ensure seamless operation. This includes:

-

Customised Workflow: The module must align with the washing and shredding stages, requiring precise engineering.

-

Automation Systems: Advanced sensors and controls monitor moisture levels, adding complexity to the system.

-

Space Requirements: Drying modules increase the footprint of the PET line, necessitating additional design considerations.

These integration efforts ensure optimal performance but contribute to the cost premium.

4. Enhanced Output Quality

The drying module directly impacts the quality of the recycled PET, enabling facilities to produce high-grade rPET for demanding applications. This added value justifies the cost for buyers prioritising quality and market competitiveness.

5. Maintenance and Longevity

High-quality drying modules are built for durability, reducing maintenance costs over time. However, the initial investment in premium components and robust construction drives up the price.

The Value of Investing in a Drying Module

While the 20% cost increase may seem significant, the benefits of a drying module often outweigh the initial expense. Here’s why industrial buyers and engineers should consider this investment:

1. Superior Product Quality

Dry PET flakes are essential for producing high-quality rPET. A drying module ensures that the final product meets stringent industry standards, such as those required for food-grade packaging.

2. Increased Operational Efficiency

By reducing moisture content, the drying module minimises energy waste in downstream processes like extrusion. This leads to lower operational costs and faster production cycles.

3. Reduced Equipment Wear

Moisture in PET flakes can cause corrosion or wear in extruders and other equipment. A drying module protects your machinery, extending its lifespan and reducing maintenance costs.

4. Market Competitiveness

High-quality rPET is in demand across industries, from packaging to textiles. A PET line with a drying module positions your facility to meet market demands and command premium prices for your output.

Diagram: PET Bottle Recycling Process with Drying Module

To illustrate the role of the drying module, here’s a simplified workflow of a Machine de recyclage de bouteilles PET:

[Input: Used PET Bottles]

↓

[Sorting & Shredding]

↓

[Washing]

↓

[Drying Module] → Removes moisture to <1%

↓

[Extrusion/Pelletising]

↓

[Output: High-Quality rPET Flakes or Pellets]

This diagram highlights the drying module’s critical position in the process, ensuring that PET flakes are ready for high-temperature processing without quality degradation.

Is the 20% Cost Increase Worth It?

For recycling facilities aiming to produce high-quality rPET, the answer is often yes. The drying module enhances product quality, reduces operational costs, and improves equipment longevity, delivering a strong return on investment. However, the decision depends on your specific needs:

-

Small-Scale Operations: If you’re processing lower volumes or targeting less demanding applications, a standard PET line without a drying module may suffice.

-

High-Volume or Premium Markets: For facilities targeting food-grade rPET or large-scale production, the drying module is a critical investment.

Choosing the Right PET Line for Your Business

When evaluating a Machine de recyclage de bouteilles PET, consider the following:

-

Production Goals: Are you targeting high-quality rPET for premium markets?

-

Budget Constraints: Can your operation justify the 20% cost increase for long-term savings?

-

Scalability: Will your facility benefit from the efficiency and quality improvements over time?

Our team at Rumtoo is here to guide you through the decision-making process, ensuring you select a system that aligns with your business objectives. With decades of experience in the recycling machinery industry, we pride ourselves on delivering innovative, reliable solutions.

Conclusion

The 20% cost increase for a PET line with a drying module reflects the advanced engineering, enhanced quality, and operational efficiencies it brings to the recycling process. For industrial buyers, engineers, and recycling professionals, this investment can unlock significant benefits, from superior rPET quality to reduced long-term costs. By understanding the role of the drying module, you can make an informed decision that aligns with your facility’s goals.

Ready to elevate your recycling operations? Explore Rumtoo’s range of PET Bottle Recycling Machines and discover how our cutting-edge solutions can drive your success. Contactez-nous aujourd'hui to discuss your needs and find the perfect system for your business.