Machine à granuler le plastique

La solution ultime pour transformer les déchets plastiques en granulés de haute qualité, conçus pour être efficaces et durables dans diverses applications de recyclage.

Paramètres techniques

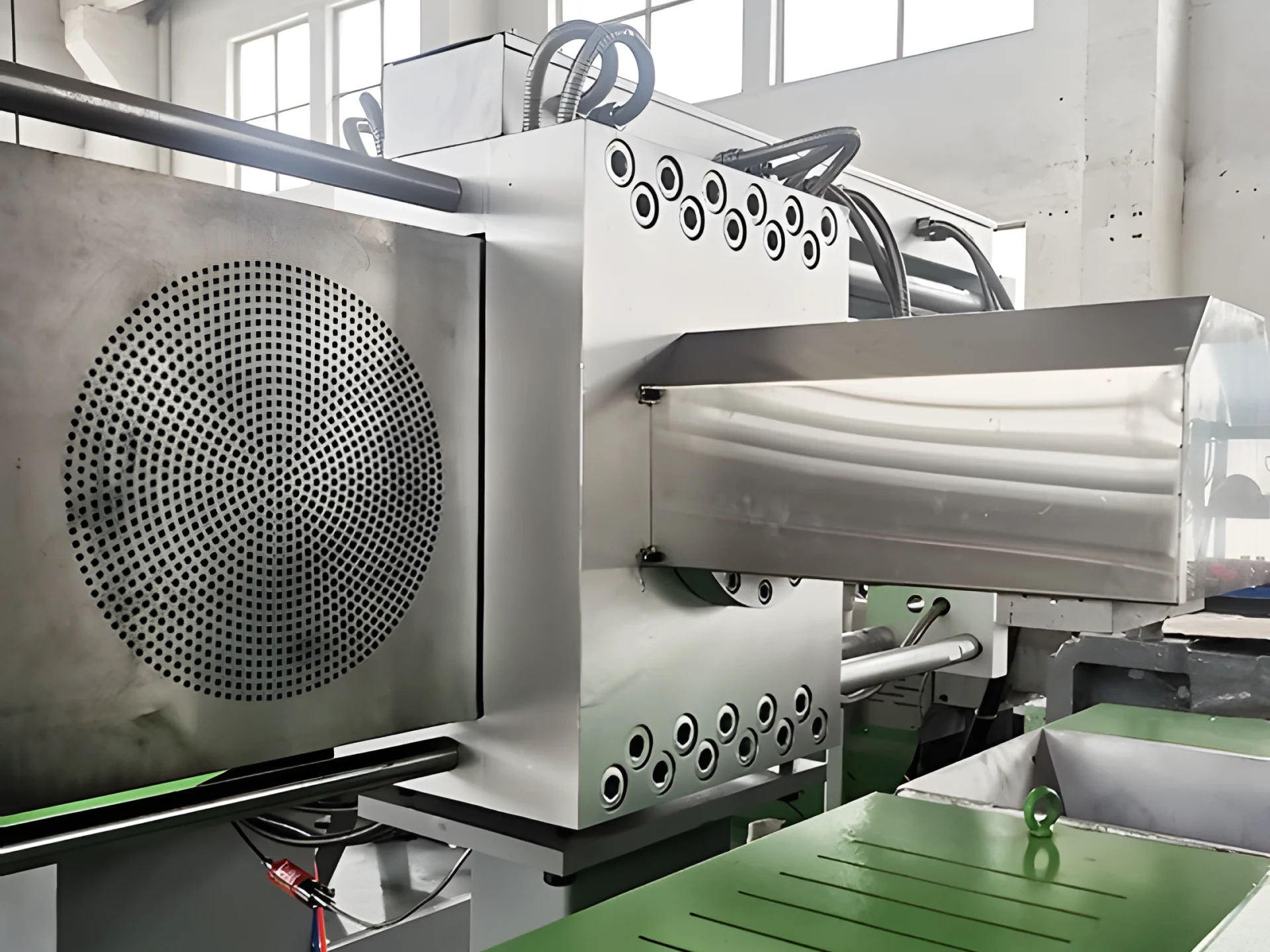

- Composants de la machine : Bande transporteuse, coupeuse compacteuse, extrudeuse, unité de granulation, unité de refroidissement à l'eau, unité de séchage, réservoir silo

- Capacité de traitement : 300-2000 kg/h

- Tension : Personnalisable (par exemple, USA 480V 60Hz, Mexique 440V/220V 60Hz, Arabie Saoudite 380V 60Hz, Nigeria 415V 50Hz)

- Compatibilité des matériaux : PEHD, PE, PP, BOPP et autres

- Taille des granulés recyclés : Réglable entre 3mm et 5mm

- Dimensions : Adapté aux besoins de l'établissement

Caractéristiques principales

-

Système de dégazage avancé

Les zones de triple dégazage éliminent l'encre, l'humidité et les substances volatiles, garantissant ainsi une qualité optimale des granulés.

-

Coupeur-compacteur intégré

Prétraite les matériaux pour une alimentation régulière et une qualité de production supérieure.

-

Contrôle automatique de la granulation

Ajuste automatiquement la vitesse et la pression de la lame pour obtenir des granulés uniformes avec un minimum d'effort.

-

Large compatibilité avec les matériaux

Traite le PEHD, le PEBD, le PP et d'autres matériaux, y compris les films fortement imprimés et laminés.

Voyez-le en action

Utilisation

-

Films imprimés et laminés

Recycle les films plastiques fortement imprimés et laminés, parfaits pour les déchets post-industriels et post-consommation.

-

Pellets de PEHD, PEBD, PP

Transforme divers plastiques en granulés de haute qualité pour le soufflage de films, l'extrusion de tuyaux et le moulage par injection.

-

Configurations personnalisables

Adaptable aux besoins spécifiques des installations de recyclage, de la capacité aux dimensions.