Bouteille en PET Lavage & Machine de recyclage

Notre ligne de lavage et de recyclage de bouteilles en PET de pointe produit des éclats propres et à valeur élevée prêts pour le marché. Conçue pour la disponibilité et la rentabilité.

Pourquoi notre ligne de lavage de bouteilles en PET délivre des résultats

Maximiser le débit tout en assurant une qualité de sortie supérieure.

Maximiser votre débit

Notre mécanisme de broyage puissant agit comme le moteur de votre ligne, traitant les matériaux plus rapidement pour augmenter la production globale de l'usine.

Atteindre une pureté supérieure

Une technologie de tri avancée élimine les contaminants avec précision, livrant des éclats recyclés de grade supérieur qui commandent de meilleurs prix.

Simplifier vos opérations

Une interface intuitive et conviviale permet à tout opérateur de gérer la ligne en toute confiance, minimisant le temps de formation et les erreurs.

Optimiser votre espace de production

Obtenez la puissance de traitement maximale dans un espace minimal. Notre conception compacte permet des aménagements flexibles.

Conçue pour une performance ininterrompue

Conçue avec des matériaux résistants, notre machine est construite pour les rigueurs d'une exploitation 24/24 et 7/7, assurant une disponibilité maximale.

Réduire les coûts d'exploitation

Une technologie intelligente et économe en énergie réduit la consommation d'énergie par tonne, réduisant directement les dépenses opérationnelles.

Résultats prouvés : voyez la différence

De déchets contaminés aux éclats prêts pour le marché de premier choix.

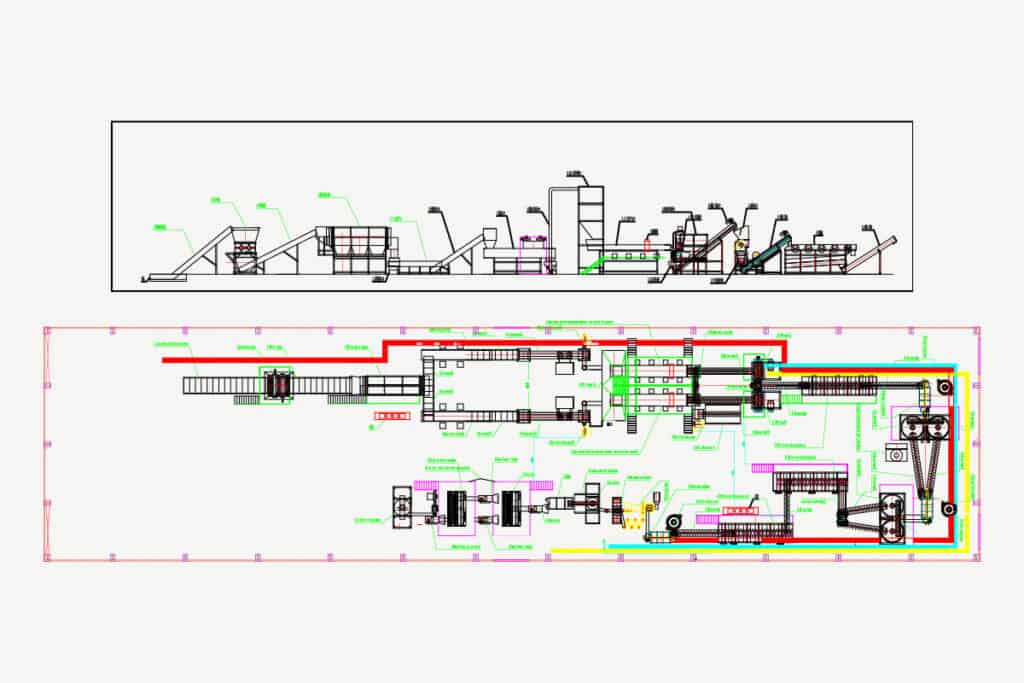

Explorez la technologie à l'intérieur

Un plongeon dans notre processus de lavage et de recyclage en plusieurs étapes.

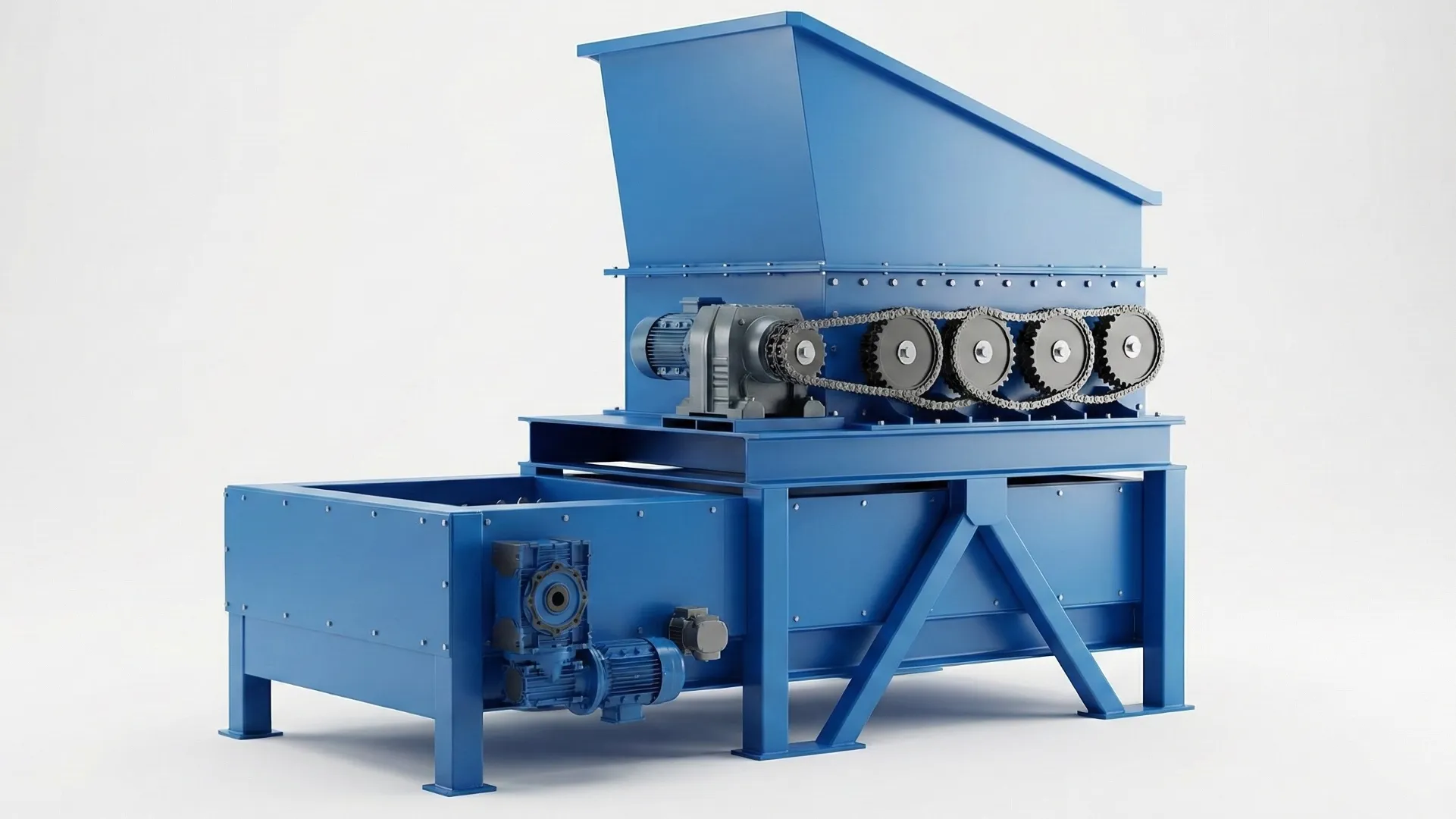

01. Machine à déballer

La première étape de notre ligne de lavage de bouteilles en plastique consiste à briser les balles compactées de bouteilles en PET en un flux fluide. Une fois que les balles sont “démantelées”, les bouteilles peuvent se déplacer librement vers la machine suivante.

02. Trommel

Un équipement optionnel, le trommel est un tunnel tournant lentement garni de petits trous qui sont légèrement plus petits que les bouteilles en PET. Les petites pièces de contamination telles que le verre, les métaux, les roches/sable et le papier tombent à travers les trous tandis que les bouteilles en PET avancent.

03. Broyeur de plastique humide

Parfois appelé granulateur de plastique, cette machine coupe les bouteilles en PET en petits éclats de 10 à 15 mm. Avec de l'eau constamment pulvérisée dans la chambre de coupe, ce processus de granulation humide prétraite et nettoie partiellement le matériau.

04. Classificateur d'air

La classification par air sépare les matériaux légers des matériaux lourds. L'objectif principal ici est d'éliminer les contaminations telles que le papier, le carton et les étiquettes en plastique des flèches PET plus lourdes à l'aide d'un flux d'air.

05. Réacteur de séparation par immersion/suspension

En utilisant l'eau comme milieu, les matériaux sont séparés par densité. Le plastique PET coule, tandis que le film plastique (étiquettes) et le PP/PE (bouchons) flottent. Un convoyeur à vis au fond déplace le PET propre à l'étape suivante.

06. Système de lavage à chaud

Les flèches PET lavées à chaud ont une valeur plus élevée car ce processus dissout les colles (à partir des étiquettes) et les résidus laissés. Utilisez de l'eau ou ajoutez des agents de lavage pour des résultats de nettoyage supérieurs.

07. Laveuse à friction

Une unité de lavage à froid efficace, la laveuse à friction à haute vitesse utilise la friction mécanique (plus de 1000 tr/min) pour enlever tout résidu difficile à enlever et tout débris des flèches PET.

08. Machine de déshydratation

La première étape du séchage. Notre machine de déshydratation centrifuge utilise un rotation à haute vitesse pour enlever une grande partie de l'eau de la surface des flèches PET avant le séchage thermique.

09. Sécheur thermique

Les flèches descendent dans des tubes en acier inoxydable mélangés à de l'air chaud, en déshydratant toute l'humidité restante. Un séparateur cyclonique mélange ensuite les flèches avec de l'air frais pour les préparer au stockage.

10. Silo de produit

Un réservoir de stockage final pour les flèches PET propres et sèches, prêt pour l'emballage ou le transport direct à une ligne de granulation.

11. Granulateur (optionnel)

Pour les clients nécessitant des granulés, nous offrons des granulateurs à tige unique et à tiges jumelées pour convertir les flèches propres en granulés de plastique de haute qualité uniformes.

Spécifications techniques

Capacités personnalisables pour répondre aux besoins de votre usine de recyclage.

Paramètres standards de la ligne

Nous proposons des solutions de 500kg/h à 3000kg/h.

| Modèle de Paramètres | PET-1000 | PET-3000 |

|---|---|---|

| Capacité d'entrée | 1000 - 1500 kg/h | 3000 - 3500 kg/h |

| Produit final | Flèches PET propres | Flèches PET propres |

| Taille des flèches | 10 - 15 mm | 10 - 15 mm |

| Taux d'humidité | < 1% | < 1% |

| Taux de PVC | < 100 ppm | < 100 ppm |

| Puissance totale | ~350 kW | ~800 kW |

Voyez la machine en action

Regardez notre machine de recyclage de bouteilles PET vérifier ses performances.

Histoires de succès de clients

Fiable par les recyclers pour fournir des flèches PET de haute qualité.

"La ligne de lavage de PET de Rumtoo a transformé notre entreprise. Le système de laveuse à chaud est exceptionnel pour enlever les colles des étiquettes, nous fournissant un produit très pur."

"L'efficacité énergétique de cette ligne est impressionnante. Nous avons constaté une diminution notable des coûts d'énergie par tonne par rapport à notre ancien équipement."

"Construction robuste et facile à entretenir. La performance de déshydratation prépare les flocons parfaitement pour nos granulateurs."

Complétez Votre Usine de Recyclage

Explorez nos autres solutions pour une installation de recyclage intégrée.

Foires aux questions

Qu'est-ce qu'une machine de recyclage de bouteilles en PET ?

Comment fonctionne la machine ?

Quels types de bouteilles en PET peuvent être traitées ?

Quels sont les avantages de l'utilisation de cette machine ?

Combien coûte une machine de recyclage de bouteilles en PET ?

Où puis-je acheter une machine de recyclage de bouteilles en PET ?

Demander un Conception Gratuit

Prêt à améliorer votre usine ? Contactez-nous pour une solution adaptée à votre installation.