Rumtoo Twin-Screw Extruders: Powering Your Production

Ready to elevate your industrial processes? Discover the robust capabilities of Rumtoo’s high-performance co-rotating twin-screw extruders. As a leading Chinese manufacturer, we bring extensive experience and cutting-edge technology to diverse sectors, including plastics recycling, chemical applications, advanced compounding, and food production. Let our twin-screw extruders be the backbone of your success.

Pourquoi choisir les extrudeuses à double vis Rumtoo ?

1. Unmatched Versatility for Diverse Applications

Rumtoo’s twin-screw extruders are true workhorses, excelling across a wide spectrum of industries. From plastics and chemicals to advanced compounding, powder coatings, food processing, and innovative wood-plastic composites, our machines are designed for adaptability. This remarkable versatility means you can confidently tackle diverse production challenges and drive innovation in your field with a reliable twin-screw extruder solution.

2. Superior Technology for Peak Performance

At Rumtoo, we integrate state-of-the-art features into every twin-screw extruder to ensure you get the best results:

- ✔Smart Modular Design: Our screws and barrels feature a sophisticated block-based modular construction. This intelligent design allows for straightforward customization to your specific needs, simplifies maintenance routines, and ensures your twin-screw extruder is ready for cost-effective future upgrades.

- ✔Série RTM hautes performances: Explore our flagship RTM series of twin-screw extruders, with models ranging from 20mm to an impressive 200mm. Each is engineered with optimized rotation speeds and torque ratings, meticulously tailored to meet your precise production demands.

- ✔Efficient Material Processing: Thanks to precisely engineered, tightly intermeshing screw elements, our twin-screw extruders achieve exceptional material conveying, melting (plastification), and compounding. This design also provides superior self-cleaning capabilities and outstanding interchangeability of screw elements, ensuring optimal performance and operational flexibility.

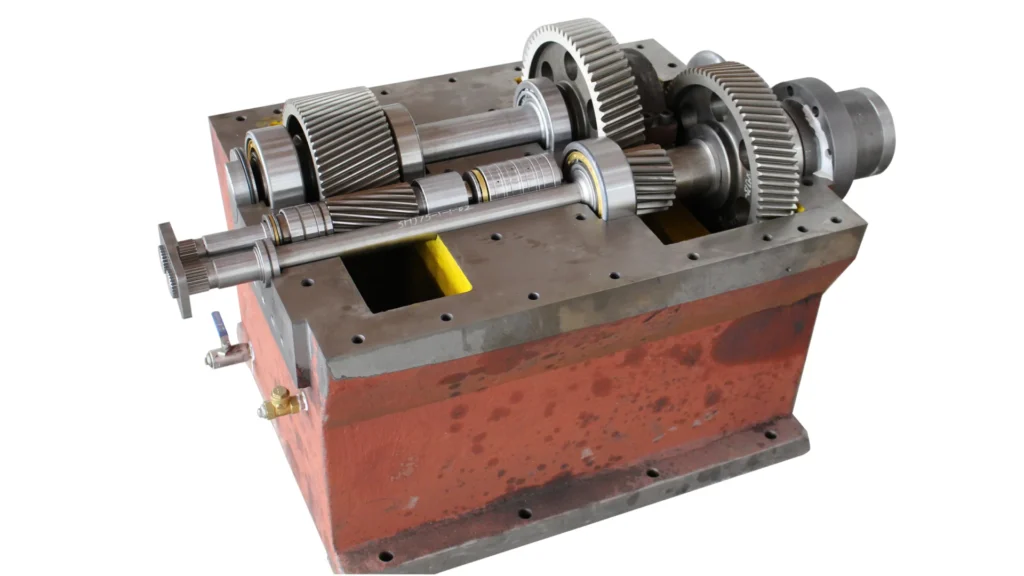

3. Robust and Reliable Power Transmission

Count on unwavering operational reliability with our advanced torque distribution system. Rumtoo twin-screw extruders incorporate precisely ground, hardened gear teeth, high-quality imported bearings, and integrated lubrication systems. This robust engineering is all designed to maximize durability and ensure your equipment delivers sustained high-performance day in and day out.

4. Durabilité forgée dans des matériaux de première qualité

Every Rumtoo twin-screw extruder is meticulously constructed from premium-grade materials, carefully selected for their resilience and suitability for diverse, demanding processing requirements. Each unit is assembled on a robust, welded base equipped with specialized adjustment pads for stability and stainless-steel covers for optimal heat retention and enhanced longevity.

5. Streamlined Operations with Advanced Screen Changers

Optimize your workflow and minimize downtime with our innovative screen-changing technology. Choose from a variety of screen changers compatible with your twin-screw extruder—including efficient basket-type, versatile plate-type, and continuous non-stop systems. These ensure uninterrupted operations and significantly boost your overall productivity.

Product Specifications: RTM Series Twin-Screw Extruders

Discover the specifics of our RTM series twin-screw extruders, designed to meet a wide array of production demands. Find the perfect match for your needs below:

| Modèle | Screw Diameter (mm) | Max. L/D Ratio | Vitesse (tr/min) | Puissance du moteur (kW) | Estimated Output (kg/h) |

|---|---|---|---|---|---|

| RTM 52B | 51.4 | 68 | 600 | 55 | 150 – 250 |

| RTM 65B | 62.4 | 68 | 600 | 90 | 200 – 350 |

| RTM75B | 71.4 | 68 | 600 | 132 | 400 – 600 |

| RTM 85B | 81 | 68 | 600 | 250 | 600 – 900 |

| RTM 95B | 93 | 68 | 600 | 315 | 800 – 1200 |

| RTM120B | 116 | 68 | 500 | 450 | 1300 – 2000 |

| RTM 135B | 133 | 68 | 500 | 900 | 2500 – 4000 |

Note: Output (kg/h) can vary based on material properties and specific processing conditions. Contact us for a detailed consultation.

Our Commitment to Your Extrusion Excellence

With over two decades of specialized expertise in screw design and twin-screw extruder manufacturing, Rumtoo proudly stands at the forefront of extrusion technology. Whether you’re aiming to boost production in the plastics, chemical, or food industries, our co-rotating twin-screw extruders are meticulously engineered to elevate your operational capabilities and help you achieve superior results. Our deep expertise translates into machines that don’t just perform—they transform your production line.

Partner with Rumtoo & Elevate Your Production

Ready to optimize your production processes and unlock new levels of efficiency with a state-of-the-art twin-screw extruder? Contact Rumtoo today! Our friendly experts are eager to learn about your specific industry needs and discuss how we can customize a high-performance extrusion solution for you.