Dans le monde du recyclage des plastiques, la qualité est roi. Et lorsqu'il s'agit du Polyéthylène Téréphtalate (PET) – le matériau des bouteilles d'eau et des contenants alimentaires – atteindre cette qualité de premier plan dépend fortement d'une étape cruciale : tri de couleur. Fabriquer des paillettes de PET recyclé de haute qualité (rPET) qui peuvent concurrencer les plastiques vierges n'est pas seulement une question de fondre des bouteilles usagées ; c'est une science précise. Plongeons donc pourquoi le tri de couleur est indispensable pour toute opération de recyclage de PET sérieuse.

Pourquoi le Tri de Couleur est-il si Essentiel pour les Paillettes de PET de Haute Qualité ?

Pensez-y comme au tri des ingrédients pour un repas gastronomique – vous ne voulez que le meilleur, et vous voulez qu'ils soient cohérents. Le tri de couleur des paillettes de PET assure cela, garantissant que le matériau recyclé final est pur, précieux et prêt pour une nouvelle vie.

Assurer l'Uniformité et la Purity : Fondament de la Qualité

Il peut vous surprendre, mais tous les PET ne sont pas créés égaux. Les colorants et additifs utilisés pour créer des bouteilles bleues, vertes ou ambre vibrantes peuvent légèrement altérer la composition chimique du plastique et son comportement de fusion. Mélanger ces derniers indistinctement peut conduire à un produit final inconstant. Le tri de couleur sépare soigneusement les paillettes par teinte, assurant que les lots de paillettes claires, bleues, vertes ou d'autres couleurs de rPET conservent des propriétés et une apparence cohérentes. Cette uniformité est essentielle pour les fabricants qui dépendent de caractéristiques matérielles prévisibles.Réduire les Taux de Contamination : Éviter les Matériaux Indésirables

La contamination est le fléau du recyclage de haute qualité. Des matériaux indésirables tels que le PVC, d'autres plastiques (PP, PE), des étiquettes résiduelles, des bouchons ou même des paillettes de PET de couleurs différentes peuvent considérablement dégrader la qualité du rPET. Les technologies de tri optique avancées sont incroyablement efficaces pour identifier et éjecter ces contaminants. En éliminant les paillettes de couleur différente et les matériaux étrangers, les trieuses de couleur réduisent considérablement la contamination, prévenant des problèmes tels que la décoloration, une réduction de la résistance ou des difficultés de traitement dans le produit final.Atteindre une Purity Ultime pour des Utilisations Demanding

Pour des applications telles que l'emballage alimentaire de grade ou les textiles de haute qualité, la pureté n'est pas seulement souhaitable – c'est inégalable. L'objectif est de produire du rPET qui soit pratiquement indistinguishable du PET vierge. Des trieuses de couleur optiques sophistiquées, souvent travaillant en tandem avec des trieuses de matière (comme celles utilisant la technologie NIR ou Near-Infrared), peuvent atteindre des niveaux de pureté supérieurs à 99%. Cela ouvre la voie à l'utilisation du rPET dans des applications à valeur élevée et sensibles, fermant ainsi le cycle.Améliorer l'Efficiency et le Débit du Recyclage

Le tri manuel est lourd de travail, lent et sujet à l'erreur humaine. Les systèmes de tri de couleur automatisés, en revanche, sont incroyablement rapides et précis. Ils peuvent traiter de vastes quantités de paillettes de PET avec une précision constante, 24h/24 et 7j/7. Cela non seulement augmente l'efficacité et le débit global de l'usine de recyclage, mais réduit également la dépendance au travail manuel, minimise la perte de matière et assure que moins de déchets finissent dans les décharges.Préserver l'Intégrité du Matériau : Clarté, Force et Processabilité

Même de petites quantités de contamination provenant de paillettes de couleur différente ou de matériaux non PET peuvent compromettre les propriétés essentielles du PET recyclé. Cela peut se manifeste par une opacité dans le rPET clair, une réduction de la résistance tensile ou des problèmes lors des processus de moulage ou d'extrusion ultérieurs. Un tri de couleur efficace est crucial pour préserver la clarté, l'intégrité structurale et la facilité de traitement que les fabricants s'attendent du rPET de haute qualité.Promouvoir l'Économie Circulaire : Impact durable

L'objectif ultime du recyclage est de créer une économie circulaire où les ressources sont utilisées, réutilisées et recyclées, minimisant les déchets et l'impact environnemental. Les paillettes de PET de haute qualité et triées par couleur sont beaucoup plus susceptibles d'être intégrées avec succès dans de nouveaux produits, souvent plusieurs fois. Cela réduit notre dépendance aux plastiques vierges (qui sont dérivés de combustibles fossiles), conserve les ressources naturelles et réduit les émissions de gaz à effet de serre associées à la production de plastique.

Le Magie du Machine : Comment Fonctionnent les Trieuses de Couleur de PET

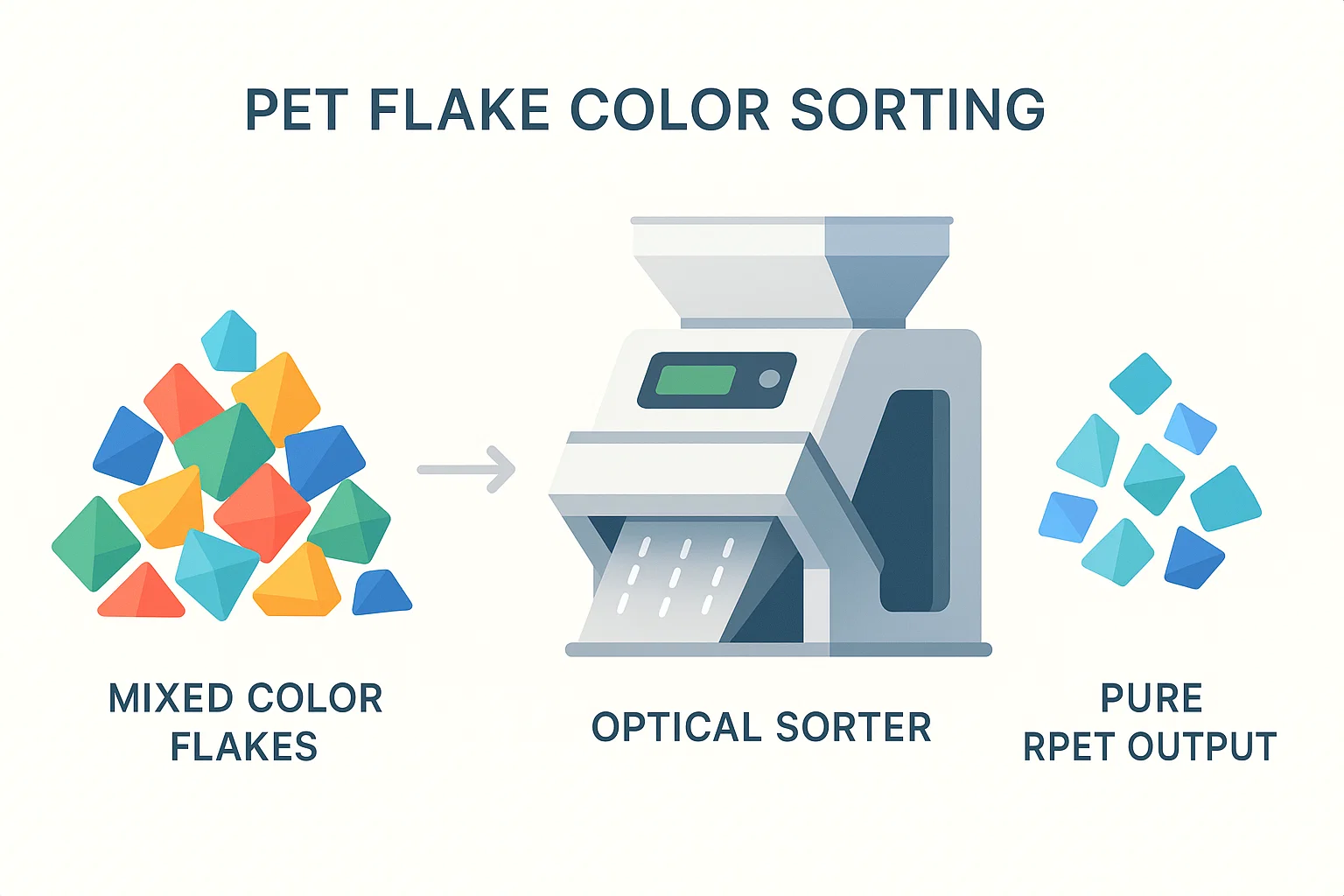

Alors, comment ce tri crucial se produit-il ? Les installations de recyclage de PET modernes emploient des trieuses optiques avancées qui sont des merveilles technologiques. Voici un aperçu simplifié du processus :

La Préparation est la Clé : Avant que les paillettes ne atteignent la trieuse de couleur, les bouteilles en PET passent généralement par un pré-tri (pour éliminer les contaminants en vrac comme d'autres plastiques, métaux et papier), un lavage (pour éliminer les étiquettes, les colles et les résidus) et un broyage en paillettes.

Alimenter les Paillettes : Les paillettes de PET nettoyées sont ensuite alimentées de manière égale sur une bande transporteuse à haute vitesse ou un tuyau.

Les “ Yeux ” de la Machine : Pendant que les paillettes se déplacent, elles passent à travers une zone d'inspection équipée de caméras haute résolution (souvent en couleur RGB), de capteurs NIR (Near-Infrared) et parfois de l'éclairage spécialisé.

Caméras : Identifient les paillettes en fonction de leur couleur.

Spectroscopie NIR : Peut différencier le PET d'autres plastiques (comme le PVC, l'PE, le PP) qui peuvent sembler similaires mais ont des signatures chimiques différentes.

Intégration de l'IA : De nombreux trieuses modernes utilisent l'Intelligence Artificielle (IA) et les algorithmes d'apprentissage automatique pour améliorer constamment l'exactitude du tri, reconnaître des défauts subtils et s'adapter aux variations des matériaux d'entrée.

Séparation rapide : Sur la base des données recueillies par les capteurs, une unité de traitement prend une décision en un clin d'œil pour chaque paillette. Si une paillette est identifiée comme colorée, d'un type de matériau différent ou comme un contaminant, un banc de jets d'air précisément orientés déclenche une bouffée d'air comprimé, expulsant la paillette indésirable du flux principal dans un récipient de collecte séparé.

Sortie pure : Le flux restant se compose de paillettes de PET de haute pureté et de couleur correcte, prêtes pour une transformation ultérieure (comme la fusion et la granulation) en rPET.

Cette approche intégrée et multi-capteur assure que seules les paillettes de PET désirées, triées par couleur et pureté du matériau, avancent, maximisant la valeur et l'utilité de la sortie recyclée.

Investir dans la qualité : Le choix intelligent pour un avenir plus vert

Le tri de couleur est bien plus qu'une étape esthétique dans le recyclage du PET ; c'est un pilier du contrôle de la qualité, de la viabilité économique et de la responsabilité environnementale. En prévenant la contamination, en assurant la cohérence du produit et en permettant la production de rPET de haute qualité comparable aux matériaux vierges, la technologie de tri de couleur avancée est indispensable.

Pour les entreprises de recyclage des plastiques, investir dans des machines de tri de couleur robustes et intelligentes n'est pas seulement une mise à niveau opérationnelle ; c'est une décision stratégique en faveur de l'efficacité accrue, de la valeur du produit supérieure et d'un engagement plus fort envers les objectifs de durabilité.