If you run a farm or manage a recycling operation, you know the frustration of facing mountains of used agricultural film at the end of each season. Mulch films, silage wraps, greenhouse covers, and stretch films come off the fields caked in soil, sand, stones, and plant residue. An agricultural film shredder turns that bulky, contaminated mess into uniform flakes you can clean, dry, and turn back into usable plastic pellets.

At Rumtoo, we design and build shredders that handle exactly these tough, dirty materials day in and day out. This guide gives you clear, step-by-step advice so you can process your farm plastic waste efficiently, cut costs, and keep your operation running smoothly. You will learn why shredding matters, how to choose the right machine, and exactly what to do to get reliable results.

The Scale and Challenges of Agricultural Film Waste

Farmers worldwide rely on plastic films to boost yields and protect crops, but the waste adds up fast. Global agricultural plastic use reaches about 12.5 million tons per year, with films making up roughly 60 percent of that total. Mulch films, silage wraps, and greenhouse covers dominate the mix. In the United States, recovered mulch often carries 30 to 80 percent contamination by weight in soil and debris.

That dirt makes everything heavier and harder to handle. Loose film takes up huge trailer space, raises transport bills, and clogs standard equipment. When left in fields or burned, the plastic breaks into microplastics that harm soil structure, water retention, and microbial life. Proper shredding solves the volume issue immediately and prepares the material for effective cleaning.

Why Shredding Is the Essential First Step

Shredding reduces the film to consistent pieces, usually 30 to 80 mm, so downstream washing and drying equipment can work efficiently. Whole sheets tangle and resist cleaning. Flakes expose more surface area for friction washers to scrub away embedded dirt.

The typical flow looks like this: collect and sort from the field, feed into the shredder, transfer flakes to a wash line, dry them, and pelletize. Without a capable shredder upfront, the entire line slows or stops. Machines built specifically for agricultural film manage the stretchiness and grit that would jam ordinary granulators or general-purpose shredders.

Types of Agricultural Film Shredders and How to Choose

Single-shaft shredders with hydraulic ram pushers stand out for this job. The pusher keeps material pressed against a slow-turning rotor fitted with staggered knives. This design delivers steady throughput and resists wrapping. Our single-shaft models for PE/PP film and woven materials reach up to 5,000 kg per hour while producing uniform flakes ready for washing.

Double-shaft shredders use two interlocking rotors to tear large bales or bulky loads apart. They work well as pre-shredders but often pair with a secondary single-shaft unit for finer control.

Specialized thin-film or spiral shredders pull and rip the material with minimal rotor contact to avoid tangles. These suit high-volume stretch-film operations.

When you evaluate machines, focus on these points:

- Throughput that matches your seasonal volume

- Reinforced wear plates and hardened D2 or similar steel knives

- Easy screen and knife access for quick maintenance

- Hydraulic drive for consistent torque on dirty loads

- Automation features such as overload reversal and PLC controls

Test your actual material with the supplier whenever possible. Samples reveal how well the machine handles your specific mix of dirt and moisture.

Explore our specialized single-shaft shredder built for agricultural film and soft plastics.

Step-by-Step Guide to Efficiently Shredding Dirty Farm Plastic

Follow this sequence to achieve consistent results and protect your equipment.

- Collect and Pre-Prepare the Film Remove obvious rocks, metal ties, or large debris at the field edge. Shake or brush off loose soil where practical, but do not aim for spotless material — the wash line will handle the rest. Cut oversized sheets into pieces one person can lift if you feed manually. Bale clean, dry film for easier transport and storage.

- Set Up the Shredder Correctly Place the machine on a solid, level foundation with ample space for infeed and outfeed conveyors. Install the screen size that matches your next process (typically 40–60 mm holes for film). Check all safety guards and emergency stops.

- Feed the Material Steadily Use a conveyor or front-end loader for safety and even flow. Start with a moderate load and increase as you monitor motor current and output quality. Avoid dumping entire bales at once. For very dusty batches, a light water mist at the hopper can reduce airborne particles and begin loosening soil.

- Monitor and Adjust During Operation Watch rotor speed, hydraulic pressure, and discharge rate. If output slows or heats up, reduce feed rate or reverse the rotor briefly to clear any buildup. Keep knives sharp — dull edges increase power draw and produce irregular flakes.

- Transfer and Store Output Move flakes immediately to the wash system via enclosed conveyors to avoid re-contamination. Cover stored flakes if they sit for more than a day.

Operators who follow this routine report steady runs of several hours with minimal stops. Training your team on these habits pays off quickly in higher daily output.

See our full range of plastic shredders designed for demanding recycling tasks.

Overcoming Common Shredding Problems

Tangling and wrapping top the list of frustrations with film. Anti-wrap rotor geometry and proper knife spacing solve most cases. If you still see buildup, pre-cut sheets longer than your rotor width or add a pre-shred step.

Abrasive dirt wears knives faster than clean plastic. Schedule inspections every 40–80 hours of operation and rotate or flip knives. Many operators keep a spare set on hand and sharpen them off-site.

Clogged screens reduce throughput. Clean them daily or install an automatic screen cleaner on larger machines.

Dust and noise affect worker comfort. Good ventilation, dust collection, and sound-dampening enclosures keep the area safe and pleasant.

Maintenance That Extends Equipment Life

Daily: Clear the hopper and check for loose bolts. Weekly: Inspect knives, screens, and wear plates. Lubricate bearings. Monthly: Service the hydraulic system and check motor alignment.

With these habits, quality shredders process hundreds of tons of dirty film before major overhauls. The investment in preventive care returns many times over in uptime and lower repair bills.

Building a Complete Recycling Line Around Your Shredder

Shredded flakes move best into a friction washer that scrubs with high-speed paddles, followed by rinse tanks, a dewatering centrifuge or squeezer, and a hot-air dryer. Pelletizing comes next — either single-stage for clean material or double-stage for dirtier loads.

Pairing the right shredder with the downstream equipment creates a smooth, continuous flow. Many farms and small recyclers start with a shredder-washer combination and expand as volume grows.

Real Benefits for Your Bottom Line and the Environment

Shredded material ships at a fraction of the original volume, slashing freight costs. Clean, pelletized LDPE sells for a solid return that often covers the entire operation within one to two seasons.

On the environmental side, you keep plastic out of landfills and fields. The U.S. Environmental Protection Agency highlights improved collection and processing of agricultural plastics as key to reducing pollution. You also cut microplastic buildup that affects soil health for years to come.

Frequently Asked Questions

Can I shred really wet or muddy film?

Yes. Robust single-shaft models handle high moisture and soil content. Follow with strong friction washing to remove the rest.

How much contamination is acceptable?

Most lines tolerate 20–40 percent dirt entering the shredder. Higher levels work if you accept faster knife wear and stronger downstream cleaning.

What safety steps matter most?

Lockout-tagout before maintenance, keep hands clear of the hopper, and use conveyors instead of manual feeding whenever possible.

How do I get started if I only have a few tons per season?

Many operators share a mobile shredder unit or partner with a local recycler until volume justifies buying their own machine.

You do not have to let dirty farm plastic waste pile up and drain your time and resources. A well-chosen agricultural film shredder plus these practical steps gives you control over the material and turns a disposal headache into a manageable, even profitable, part of your operation.

Ready to process your waste more efficiently? Share details about your film types and volume, and we will help you find the right configuration.

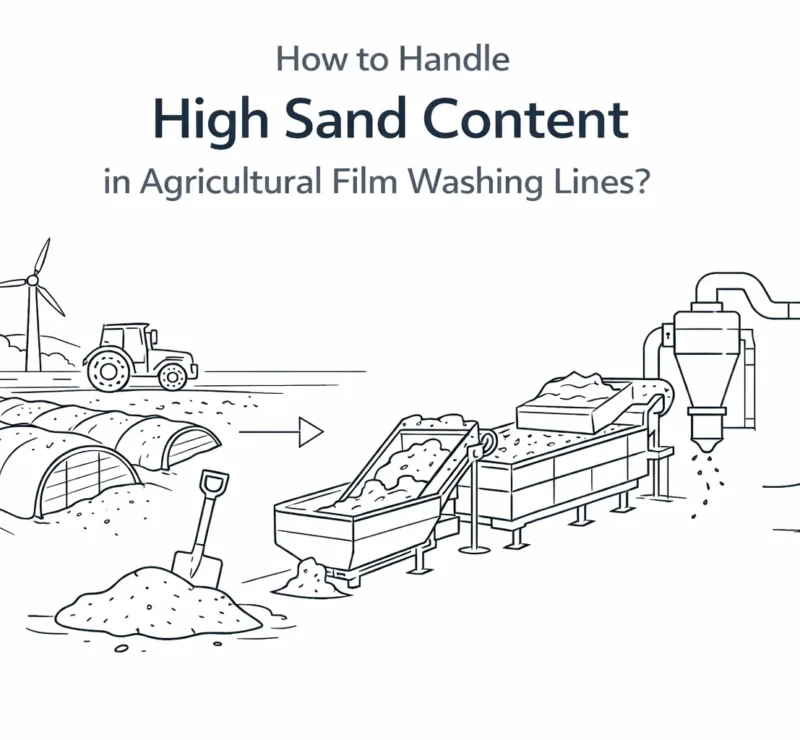

If you run an agricultural film washing line in the US market, you already know the biggest problem is not plastic itself. It is the sand and soil packed into used mulch film after field use.

Sand is abrasive. It wears shredder knives, damages pumps, clogs screens, and shows up later as hard inclusions that drag down pellet quality. The most reliable approach is not one “strong” washer, but a staged process designed to remove heavy contamination early and keep it from recirculating:

- Pre-washing (Pre-wash) to knock off bulk dirt and break up clumps.

- Friction washing (Friction washer) to detach stubborn sand and soil from folds and creases.

- Sink-float separation (Sink-float tank) to continuously reject sand, stones, grit, and other heavy contaminants once they are fully released into the water stream.

This guide explains how to combine these steps to remove sand from plastic film efficiently, protect your equipment, and stabilize downstream extrusion.

Why agricultural mulch film carries extreme sand load

Post-consumer agricultural film (especially field-collected mulch film) typically arrives with:

- Soil and fine sand embedded into wrinkles and folds

- Stones, grit, and occasional metal pieces from collection and baling

- Organic residues such as roots and plant matter

- Moisture and sticky contaminants (pesticides, fertilizers, adhesives)

If sand is not removed early, it will:

- Accelerate wear on shredder knives and cutting chambers

- Increase abrasion in friction washers, pumps, and piping

- Reduce sink-float efficiency as the tank turns into “mud water”

- Increase melt filtration load and screen-change frequency during pelletizing

The proven combo: Pre-washing + Friction washing + Sink-float

Instead of trying to fix everything in one place, design the agricultural film washing line to remove contamination in stages.

1) Pre-washing (Pre-wash)

Goal: Remove loose sand and soil before intensive washing and separation.

What pre-washing does well:

- On sand-heavy mulch film, a properly designed pre-wash can remove up to 60–70% of heavy solids (sand/soil/grit) before the main washing steps.

- Reduces the dirt load entering your core washing steps

- Prevents mud buildup across the entire line

- Improves stability of downstream sink-float and friction washing

Practical best practices:

- Use enough agitation to break up compacted soil.

- Include a simple de-sanding / settling area so heavy particles can drop out and be discharged.

- Keep the pre-wash zone easy to access for cleaning.

2) Friction washing (High-speed scrubbing)

Goal: Mechanically scrub soil and residue off the film surface.

Friction washing is the workhorse step for dirty mulch film because it:

- Scrubs embedded soil out of folds and creases

- Breaks the bond between sand and plastic surface

- Helps remove organic residues and sticky contaminants

Why we place friction washing before sink-float for sand-heavy mulch film:

- Friction washing detaches stubborn sand so it becomes free solids in the water stream.

- In the next step, the sink-float tank can reject those freed heavy solids reliably.

Key considerations:

- High rotor speed plus a properly matched screen improves scrubbing.

- A steady feed rate prevents overload and keeps cleaning consistent.

- Even spray and rinse water distribution supports washing without turning the system into mud recirculation.

3) Sink-float separation (Density separation)

Goal: Remove heavy contaminants using density differences.

In a sink-float tank:

- PE film floats

- Sand, soil, stones, grit, and metals sink

Why this step is essential for sand removal:

- It provides continuous heavy-particle rejection.

- It protects downstream equipment and stabilizes pelletizing quality.

Design and operating tips that matter in the real world:

- Keep water flow and level stable to avoid re-mixing settled solids.

- Make sure the sinking discharge section can handle high sand volume.

- Keep the tank water clear enough for stable separation. If the tank runs muddy, separation performance drops.

Recommended process flow for high-contamination mulch film

A common workflow for sand-heavy agricultural film looks like:

- Shredding / size reduction

- Pre-washing (bulk dirt removal)

- Friction washing (deep scrubbing)

- Sink-float tank (heavy contaminant separation)

- Dewatering / drying (squeeze + centrifugal drying)

- Pelletizing with filtration

Depending on input quality, you may add an extra rinse or a second friction stage. The core concept stays the same: remove sand early, separate heavy solids continuously, and scrub thoroughly.

How to verify you are actually removing sand

Simple checks used on working lines:

- Visual check: flakes should look bright and clean, not gray or muddy.

- Sediment test: take a cup of process water and let it settle. Heavy settling indicates solids are still circulating.

- Wear indicators: repeated pump seal failures, screen damage, and unusually fast knife wear typically point to poor early sand removal.

- Pellet quality: fewer hard inclusions and fewer black specs generally indicate better contamination control.

Common reasons sand stays in the line

- Skipping pre-washing and pushing all dirt into friction washing

- Running the sink-float tank with muddy water (separation becomes unstable)

- Under-sizing the sinking discharge (sand builds up and returns to the process)

- Expecting one tank or one washer to solve a staged contamination problem

Equipment reference: Agricultural film washing & recycling machine

For a full line designed for high-contamination agricultural film, see:

Summary

To remove sand from plastic film at industrial scale, focus on process design—not just one piece of equipment. A dependable agricultural film washing line combines:

- Pre-washing to reduce bulk dirt load

- Sink-float separation to continuously reject heavy contaminants

- Friction washing to scrub soil out of folds and creases

Done right, this combination improves purity, reduces wear, and keeps pelletizing stable.

Stop wasting money on virgin material. The SMF Series Fully Automatic PVC Pulverizer converts coarse regrind into high-quality, free-flowing powder (20-80 mesh) that can be reused directly in your extrusion line up to 100%.

Crushing scrap pipes creates "flakes" (8-12mm). While flakes are useful, they cannot be used in all extrusion processes, especially for high-quality pipes or profiles where surface finish is critical. Flakes often cause uneven melting or rough surfaces.

To maximize your scrap value, you need to grind it down to the same consistency as virgin resin. Our Fully Automatic PVC Pulverizer (also known as a Plastic Miller) is designed specifically for heat-sensitive Rigid PVC.

Why Choose the SMF Series Pulverizer?

Dual Cooling System

PVC degrades if overheated. Our machine uses both Water Cooling (jacketed housing) and Air Cooling to keep the grinding chamber temperature low, preventing material discoloration.

High-Quality Powder

Adjustable gap between rotary and fixed knives allows you to precisely control the mesh size (20-80 mesh). The vibrating sieve automatically returns coarse particles for re-grinding.

Fully Automatic Control

Equipped with a PLC and Vibro-feeder. The system monitors the main motor amp load and automatically adjusts the feeding speed to prevent overloading.

How It Works: The Process Flow

The transition from "Waste" to "Resource" happens in a closed-loop system:

- Feeding: PVC flakes are fed into the hopper via a vibro-feeder.

- Milling: A high-speed rotor (disc type) grinds the material against fixed toothed plates. The friction creates the powder.

- Cooling: A water jacket circulates around the chamber to absorb heat instantly.

- Screening: A vacuum loader pulls the powder to a cyclone separator and a vibrating sieve.

- Recirculation: Fine powder goes to the silo; coarse powder returns to the mill automatically.

Technical Specifications

Select the model based on your required throughput capacity (kg/h).

| Model | Disc Diameter | Motor Power (kW) | Capacity (kg/h)* | Mesh Size |

|---|---|---|---|---|

| SMF-500 | 500 mm | 37 - 45 kW | 150 - 250 kg/h | 20 - 80 Mesh |

| SMF-600 | 600 mm | 55 - 75 kW | 300 - 450 kg/h | 20 - 80 Mesh |

| SMF-800 | 800 mm | 75 - 90 kW | 500 - 800 kg/h | 20 - 80 Mesh |

*Capacity depends on the material formulation (CaCO3 percentage) and required mesh size. Higher calcium content is easier to grind.

Long-Life Grinding Discs

The heart of a pulverizer is the grinding disc. We use SKD-11 or D2 high-quality alloy steel for our blades.

Unlike standard crushers that need sharpening weekly, our pulverizer discs typically last 4-6 months (depending on throughput) before needing re-sharpening. When they do wear out, they can be re-sharpened multiple times to extend service life.

Frequently Asked Questions

Why is water cooling necessary for PVC?

Rigid PVC is heat-sensitive. Without water cooling, the friction heat from grinding would cause the powder to melt or turn yellow/black, ruining the material quality.

What mesh size should I use for PVC pipes?

For standard PVC pipes, 30-60 mesh is common. For profiles or more delicate extrusions, 60-80 mesh is preferred to ensure a smooth surface finish.

Can this machine handle soft PVC?

No. This model (SMF Series) is specifically designed for Rigid PVC (uPVC). Soft PVC requires a different type of cryogenic grinding system.

Get High-Quality Powder Today

Ready to turn your scrap into valuable raw material? Send us your capacity requirements and target mesh size.

We offer:

- ✔ Free Testing Video

- ✔ Layout Design

- ✔ 12-Month Warranty

Request Pricing for SMF Pulverizer →

In today's increasingly environmentally conscious world, businesses are seeking innovative solutions to reduce their ecological footprint while simultaneously improving their bottom line. Investing in a plastic bottle recycling machine, specifically for PET bottles, is a powerful strategy that delivers on both fronts. This comprehensive guide will delve into the compelling reasons why a PET bottle recycling machine is a smart investment and provide a detailed, step-by-step roadmap for selecting the ideal one for your operational needs.

Essential Reasons to Invest in a PET Bottle Recycling Machine

Beyond mere compliance, embracing PET bottle recycling offers a multitude of tangible and intangible benefits that can significantly impact your business's success and reputation.

1. Champion Environmental Stewardship: Reduce Your Carbon Footprint

The most immediate and impactful benefit of recycling PET bottles is its profound positive environmental impact. By processing discarded PET, your business actively contributes to:

- Resource Conservation: Less virgin PET production means fewer fossil fuels consumed and reduced reliance on non-renewable resources.

- Reduced Landfill Waste: Diverting plastic bottles from landfills mitigates the growing problem of plastic pollution and extends landfill lifespans.

- Lower Greenhouse Gas Emissions: Recycling PET uses significantly less energy than producing new plastic from raw materials, leading to a substantial reduction in greenhouse gas emissions.

By visibly committing to these sustainable practices, your company not only aligns with global sustainability goals but also demonstrates a deep commitment to environmental responsibility, resonating with eco-conscious consumers and stakeholders.

2. Unlock Significant Cost Savings: Optimize Your Operations

Investing in a PET bottle recycling machine can lead to substantial and ongoing cost savings, directly impacting your operational efficiency and profitability.

- Reduced Raw Material Costs: For businesses that utilize PET in their own products, recycling allows for the reuse of plastic, minimizing or even eliminating the need to purchase new virgin materials.

- Lower Waste Management Expenses: By processing your own PET waste, you significantly decrease the volume of waste sent to landfills, leading to substantial savings on waste collection and disposal fees.

These combined savings can quickly offset the initial investment in the recycling machine, providing a clear financial incentive for adoption.

3. Cultivate New Revenue Streams: Embrace the Circular Economy

A PET bottle recycling machine isn't just an expense; it's an asset that can generate new income for your business.

- Selling Recycled PET: Processed PET flakes or pellets are a valuable commodity in the recycling market. You can sell these materials to other manufacturers who use recycled content in their products, creating a new and consistent revenue stream.

- Internal Product Manufacturing: If your business produces goods using PET, the recycled material can be re-incorporated into your own manufacturing process, leading to a more circular and sustainable production model while reducing external sourcing costs.

This ability to transform waste into a valuable resource is a cornerstone of the circular economy, offering a robust return on investment.

4. Ensure Regulatory Compliance: Stay Ahead of the Curve

The global regulatory landscape for waste management and recycling is constantly evolving and becoming more stringent. Proactively investing in an in-house plastic bottle recycling machine ensures your business:

- Meets Local and International Regulations: Avoid potential fines and legal repercussions by adhering to increasingly strict waste disposal and recycling mandates.

- Enhances Corporate Reputation: Demonstrating a commitment to responsible waste management showcases your company as a responsible corporate citizen, a factor increasingly valued by consumers, investors, and partners.

Staying ahead of regulatory requirements not only mitigates risks but also positions your business as a leader in sustainable practices.

5. Boost Brand Image and Foster Customer Loyalty: Connect with Conscious Consumers

In today's market, consumers are increasingly making purchasing decisions based on a company's ethical and environmental practices.

- Improved Brand Perception: Visibly committing to recycling efforts through an in-house PET bottle recycling machine enhances your brand image, portraying your company as environmentally responsible and forward-thinking.

- Attract Eco-Conscious Customers: Sustainability is a powerful differentiator. Your commitment to recycling can attract a growing segment of consumers who prioritize eco-friendly businesses.

- Foster Customer Loyalty: Consumers often feel a stronger connection to brands that align with their values. By demonstrating environmental responsibility, you can build deeper trust and loyalty with your customer base.

These intangible benefits translate into increased market share and long-term business success.

Step-by-Step Guide to Choosing the Right PET Bottle Recycling Machine

Selecting the optimal PET bottle recycling machine is crucial for maximizing your investment and ensuring efficient operations. This guide will walk you through the key considerations.

Understanding Your Business Needs: Laying the Foundation

Before diving into machine specifications, a thorough assessment of your operational requirements is essential.

- Assess Your Volume Requirements: Accurately determine the quantity of PET bottles your business handles on a daily, weekly, and monthly basis. This critical data will directly inform the required processing capacity of your machine.

- Evaluate Space Availability: Carefully consider the physical space available for the machine installation. Remember to account for not only the machine's footprint but also adequate room for material handling, storage of incoming bottles, and processed recycled material.

- Define Your Budget Considerations: Establish a clear budget for this investment. Beyond the initial purchase price, factor in installation costs, ongoing maintenance expenses, and operational costs such as electricity and labor. A comprehensive budget will prevent unexpected financial burdens.

Key Features to Look For: What Makes a Machine Stand Out?

Once you understand your needs, focus on the technical specifications that will ensure optimal performance.

- Processing Speed (Throughput): Choose a machine whose processing speed aligns with your volume requirements. High-volume operations necessitate a faster machine to maintain efficiency and avoid bottlenecks.

- Energy Efficiency: Prioritize machines designed for energy efficiency. This will not only minimize your operational costs over time but also further reduce your environmental impact, aligning with your sustainability goals.

- Ease of Operation and Maintenance: Opt for a machine that is user-friendly and requires straightforward maintenance procedures. This ensures smooth daily operations, reduces the need for specialized technical skills, and minimizes costly downtime.

- Quality of Output: Critically evaluate the quality of the recycled PET material the machine produces. If you plan to sell the recycled material or use it in your own products, it must meet industry standards for purity, size, and other specifications. A high-quality output maximizes the value of your recycled material.

Calculating Potential Return on Investment (ROI): Justifying Your Investment

A strong ROI is key to securing internal buy-in and demonstrating the financial viability of your investment.

- Compare Initial Costs vs. Long-Term Savings: Conduct a detailed financial analysis, comparing the initial capital expenditure with the projected long-term savings on raw material purchases and waste management fees. Often, a higher upfront cost for a more efficient and durable machine can be justified by significant savings and increased revenue over its lifespan.

- Estimate Revenue from Recycled PET: Research current market rates for recycled PET flakes or pellets. Based on your projected output volume, estimate the potential revenue you can generate from selling this valuable commodity.

- Factor in Intangible Benefits: While harder to quantify directly, consider the substantial intangible benefits. Improved brand image, increased customer loyalty, enhanced regulatory compliance, and a stronger reputation as a sustainable company can indirectly contribute to significant financial gains through increased sales and avoided penalties.

Finalizing Your Decision: Making an Informed Choice

The final steps involve due diligence and securing the best possible partnership.

- Research Manufacturers and Suppliers: Thoroughly investigate various manufacturers and suppliers of plastic bottle recycling machines. Look for companies with a proven track record, positive customer reviews, and a reputation for reliable products and excellent after-sales support.

- Request Detailed Quotes and Proposals: Obtain comprehensive quotes and proposals from multiple reputable vendors. Compare them not only on price but also on included features, warranty, installation services, and ongoing support.

- Conduct Site Visits and Demonstrations (If Possible): Whenever feasible, arrange to visit facilities where the machines you are considering are currently in operation. This provides invaluable firsthand insight into their performance, reliability, and ease of use in a real-world setting.

- Prioritize After-Sales Support and Training: Confirm that the supplier offers comprehensive after-sales support, including technical assistance, spare parts availability, and training programs for your staff. This is paramount for maintaining efficient operations, troubleshooting any issues promptly, and maximizing the lifespan of your machine.

Conclusion

Investing in a plastic bottle recycling machine for PET is more than just an operational upgrade; it's a strategic imperative for businesses aiming to enhance both their sustainability credentials and their financial profitability. By meticulously assessing your specific needs, diligently evaluating key machine features, and thoroughly calculating your potential return on investment, you can confidently select the ideal machine. This pivotal decision will not only align with your business goals but also secure a robust and rewarding return on investment, propelling your company towards a more sustainable and prosperous future.