Welcome to “Rumtoo” Plastic Recycling Machinery, where high-quality PP/PE film recycling machinery is our top priority. Our machines are designed with the features of easy operation, easy maintenance, and reasonable prices. Our experienced engineers are ready to provide you with detailed operation manuals, technical documents, and timely after-sales service.

At the same time, we also provide free product design services. We are committed to customizing production solutions for customers, making production more efficient and environmentally friendly, thereby forming the core competitiveness of sustainable development and contributing to global energy conservation, emission reduction, and green economic development, striving to create a better life.

Our products include: plastic recycling lines, plastic washing lines, shredders, crushers, compaction granulation systems, and film extruders.

Customers are our respected employers, and your requirements will be fully respected here.

Our Approach

OUR MISSION IS TO BE THE BEST IN PLASTIC RECYCLING MACHINERY INDUSTRY!

A FULL SERVICE

Dedicated Team

Best Engineers

24/7 Supports

Company Vision

Advancing the Future of Plastic Recycling

We provide a full range of services, including preliminary design, manufacturing, after-sales service, etc.

MEET OUR TEAM

EXCHANGE FRESH THINKING AND

EMBRACE NEW TECHNOLOGIES

This letter is to inform you that our supplier has been a very good supplier. In our many dealings with them, we have found them to be reliable and trustworthy and we highly recommend them to you as a supplier.

MR. DAMIAN FLEGEL

CEOI confirm that our company in Australia has worked with Rumtoo for over five years and are very happy torecommend them for your requirements. We are very impressed with their fast service and quality equipment.

Maria Flynn

DR. ADRIAN SANCHEZ ROAThis trade reference letter is to confirm that we have purchased equipment from Rumtoo and found them to be very easy to work with, professional and trustworthy. We would certainly work with them again on future equipment purchases and higher recommend them to others.

Gina Kennedy

MARK R.ALT,PE Director of EngineeringOUR PRODUCTS

KEEP ALWAYS UPDATED WITH

OUR FRESH BLOG AND PRODUCT POSTS

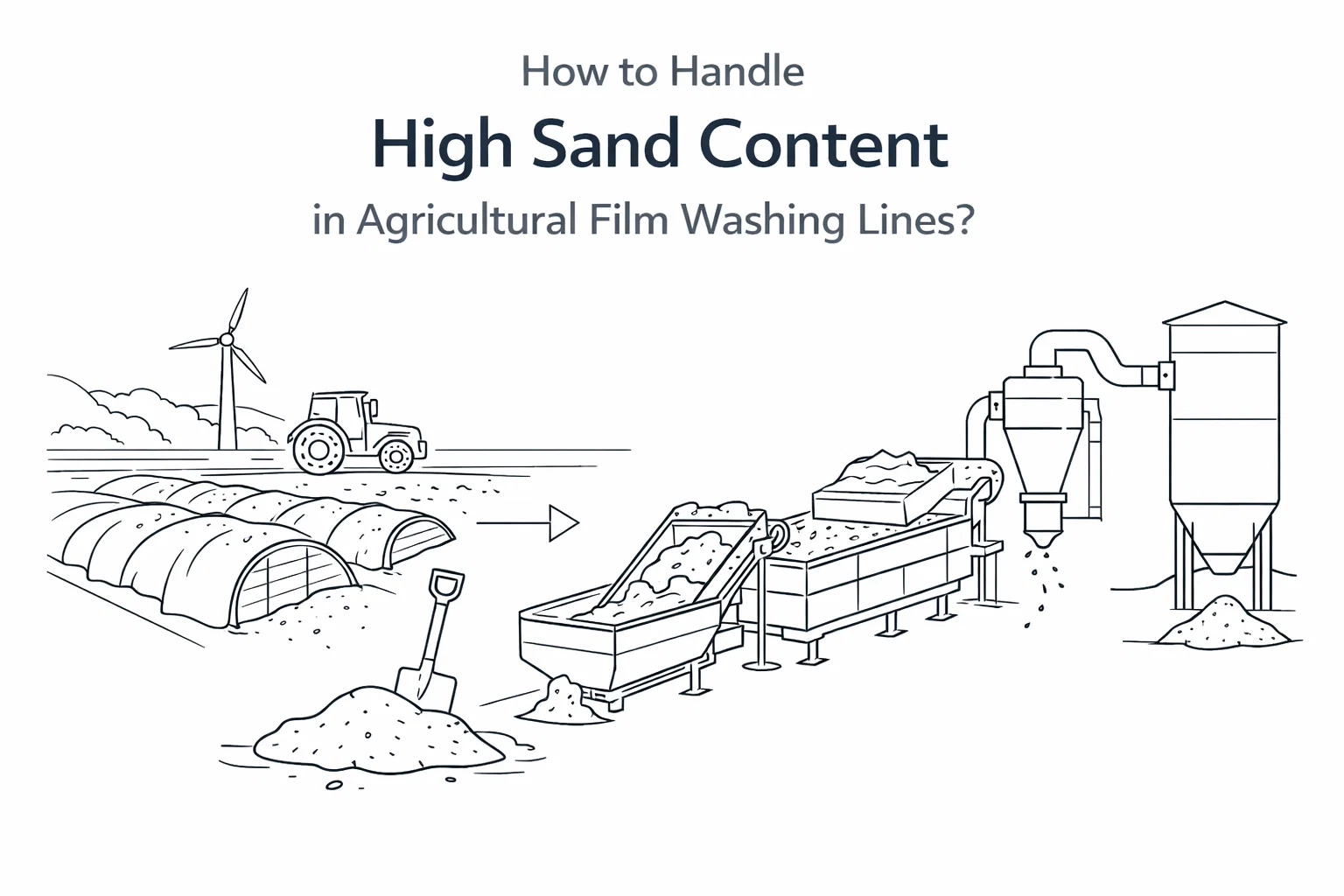

If you run an agricultural film washing line in the US market, you already know the biggest problem is not plastic itself. It is the sand and soil packed into used mulch film after field use.

Sand is abrasive. It wears shredder knives, damages pumps, clogs screens, and shows up later as hard inclusions that drag down pellet quality. The most reliable approach is not one “strong” washer, but a staged process designed to remove heavy contamination early and keep it from recirculating:

- Pre-washing (Pre-wash) to knock off bulk dirt and break up clumps.

- Friction washing (Friction washer) to detach stubborn sand and soil from folds and creases.

- Sink-float separation (Sink-float tank) to continuously reject sand, stones, grit, and other heavy contaminants once they are fully released into the water stream.

This guide explains how to combine these steps to remove sand from plastic film efficiently, protect your equipment, and stabilize downstream extrusion.

Why agricultural mulch film carries extreme sand load

Post-consumer agricultural film (especially field-collected mulch film) typically arrives with:

- Soil and fine sand embedded into wrinkles and folds

- Stones, grit, and occasional metal pieces from collection and baling

- Organic residues such as roots and plant matter

- Moisture and sticky contaminants (pesticides, fertilizers, adhesives)

If sand is not removed early, it will:

- Accelerate wear on shredder knives and cutting chambers

- Increase abrasion in friction washers, pumps, and piping

- Reduce sink-float efficiency as the tank turns into “mud water”

- Increase melt filtration load and screen-change frequency during pelletizing

The proven combo: Pre-washing + Friction washing + Sink-float

Instead of trying to fix everything in one place, design the agricultural film washing line to remove contamination in stages.

1) Pre-washing (Pre-wash)

Goal: Remove loose sand and soil before intensive washing and separation.

What pre-washing does well:

- On sand-heavy mulch film, a properly designed pre-wash can remove up to 60–70% of heavy solids (sand/soil/grit) before the main washing steps.

- Reduces the dirt load entering your core washing steps

- Prevents mud buildup across the entire line

- Improves stability of downstream sink-float and friction washing

Practical best practices:

- Use enough agitation to break up compacted soil.

- Include a simple de-sanding / settling area so heavy particles can drop out and be discharged.

- Keep the pre-wash zone easy to access for cleaning.

2) Friction washing (High-speed scrubbing)

Goal: Mechanically scrub soil and residue off the film surface.

Friction washing is the workhorse step for dirty mulch film because it:

- Scrubs embedded soil out of folds and creases

- Breaks the bond between sand and plastic surface

- Helps remove organic residues and sticky contaminants

Why we place friction washing before sink-float for sand-heavy mulch film:

- Friction washing detaches stubborn sand so it becomes free solids in the water stream.

- In the next step, the sink-float tank can reject those freed heavy solids reliably.

Key considerations:

- High rotor speed plus a properly matched screen improves scrubbing.

- A steady feed rate prevents overload and keeps cleaning consistent.

- Even spray and rinse water distribution supports washing without turning the system into mud recirculation.

3) Sink-float separation (Density separation)

Goal: Remove heavy contaminants using density differences.

In a sink-float tank:

- PE film floats

- Sand, soil, stones, grit, and metals sink

Why this step is essential for sand removal:

- It provides continuous heavy-particle rejection.

- It protects downstream equipment and stabilizes pelletizing quality.

Design and operating tips that matter in the real world:

- Keep water flow and level stable to avoid re-mixing settled solids.

- Make sure the sinking discharge section can handle high sand volume.

- Keep the tank water clear enough for stable separation. If the tank runs muddy, separation performance drops.

Recommended process flow for high-contamination mulch film

A common workflow for sand-heavy agricultural film looks like:

- Shredding / size reduction

- Pre-washing (bulk dirt removal)

- Friction washing (deep scrubbing)

- Sink-float tank (heavy contaminant separation)

- Dewatering / drying (squeeze + centrifugal drying)

- Pelletizing with filtration

Depending on input quality, you may add an extra rinse or a second friction stage. The core concept stays the same: remove sand early, separate heavy solids continuously, and scrub thoroughly.

How to verify you are actually removing sand

Simple checks used on working lines:

- Visual check: flakes should look bright and clean, not gray or muddy.

- Sediment test: take a cup of process water and let it settle. Heavy settling indicates solids are still circulating.

- Wear indicators: repeated pump seal failures, screen damage, and unusually fast knife wear typically point to poor early sand removal.

- Pellet quality: fewer hard inclusions and fewer black specs generally indicate better contamination control.

Common reasons sand stays in the line

- Skipping pre-washing and pushing all dirt into friction washing

- Running the sink-float tank with muddy water (separation becomes unstable)

- Under-sizing the sinking discharge (sand builds up and returns to the process)

- Expecting one tank or one washer to solve a staged contamination problem

Equipment reference: Agricultural film washing & recycling machine

For a full line designed for high-contamination agricultural film, see:

Summary

To remove sand from plastic film at industrial scale, focus on process design—not just one piece of equipment. A dependable agricultural film washing line combines:

- Pre-washing to reduce bulk dirt load

- Sink-float separation to continuously reject heavy contaminants

- Friction washing to scrub soil out of folds and creases

Done right, this combination improves purity, reduces wear, and keeps pelletizing stable.