Rigid Plastics Shredder Machine

Engineered for tough rigid plastics (HDPE/PP/ABS/PC): crates, pallets, pipes, housings, injection sprues, and extruder purgings/lumps—delivering stable size reduction and efficient volume reduction for downstream recycling.

Why Choose Our Rigid Plastics Shredder?

Built for bulky, thick, and high-strength rigid plastics—focused on stable throughput, safety, and serviceability.

Continuous Feeding, Fewer Jams

Designed for bulky and irregular rigid plastic parts. A stable feeding structure helps maintain throughput and reduce unplanned stoppages caused by bridging or clogging.

Aggressive Cutting for Thick-Wall Rigid Plastics

A heavy-duty rotor paired with wear-resistant knives handles thick pipes, pallets, rigid sheet/parts, and dense lumps with reliable cutting performance.

Service-Friendly, Lower Operating Cost

Maintenance-oriented design supports routine servicing and parts replacement. Knife and wear-part configurations can be optimized for your material to extend service life.

Smart Controls, Safe Operation

PLC control supports start/stop, forward/reverse, and automatic overload protection to improve safety and stability in long-running recycling operations.

Materials & Applications

Rigid plastics are strong and dimensionally stable, widely used in household and industrial products. Shredding is a key first step to reduce size and improve downstream washing and pelletizing efficiency.

Typical Products

- Bins, totes, crates, and housings (appliances, electronics, industrial casings)

- Plastic pallets, rigid sheets, thick thermoformed parts, and off-cuts

- HDPE/PVC/PP pipes and thick-wall fittings

- Injection sprues/runners and extruder purgings/lumps

Common Polymers

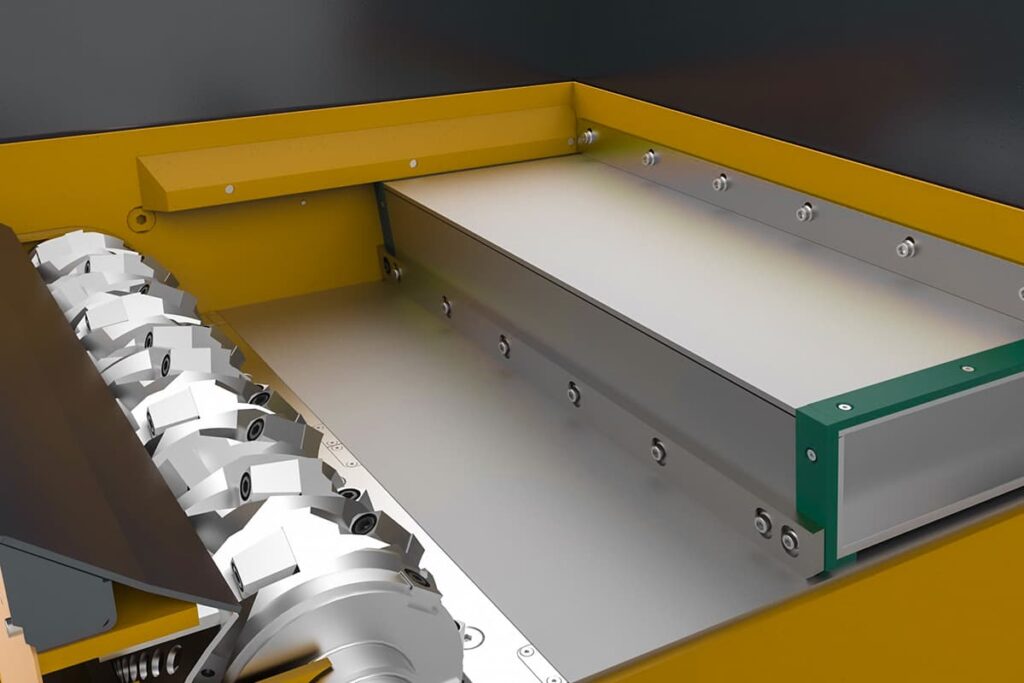

Working Principle & Key Components

Optimized for rigid plastics—from feeding and cutting to safe discharge.

How Does a Rigid Plastics Shredder Work?

Material enters the hopper and is guided toward the rotating rotor. The rotor knives shear the plastic against a fixed counter-knife for stable size reduction. Once the pieces meet the target size, they discharge and proceed to downstream recycling steps.

- Hopper / feeding structure: Improves feeding for bulky rigid parts and reduces bridging risk.

- Rotor & knives: Wear-resistant design for long service life on rigid plastics.

- Coupling transmission: Reduces vibration and protects the main shaft and gearbox.

- PLC control system: Start/stop, forward/reverse, and overload protection for safer operation.

Specifications & Configuration

Configurations can be recommended based on your material type, throughput, and target output size.

| Model | DS-800 | DS-1000 | DS-1200 | DS-1500 |

|---|---|---|---|---|

| Number of Rotary Blades | 30 pcs | 39 pcs | 48 pcs | 57 pcs |

| Motor Power | 30 kW | 37 kW | 55 kW | 75 kW |

| Knife Material | SKD11 | SKD11 | SKD11 | SKD11 |

| Rotor Diameter | Φ275 | Φ315 | Φ375 | Φ400 |

| Approx. Output (kg/h) | 450 | 800 | 1200 | 1500 |

| Rotating Speed (rpm/min) | 82 | 82 | 82 | 82 |

Proof: Build Quality, Safety & Serviceability

For industrial purchasing, details matter. Below are the checkpoints and options we can provide to support a reliable rigid plastics shredder machine selection.

Manufacturing & QC Evidence

Process controls and inspection checkpoints that reduce risk.

- Bearing / gearbox options: Brand options available on request (per project and supply chain).

- Heat treatment: Knife and wear-part heat treatment process matched to your material (rigid plastics / light contamination).

- Rotor dynamic balancing: Helps minimize vibration, noise, and bearing wear.

- Assembly tolerances: Critical-fit checks for shaft, coupling, and bearing seats.

- Pre-shipment testing (FAT): No-load + functional run, current draw, temperature rise, and control logic verification; test video available.

Safety & Protection

Designed to protect people and equipment in real-world recycling.

- Overload logic: PLC monitors load and triggers protection to avoid motor/drive damage.

- Reverse strategy: Auto reverse / recovery logic for bridging or stalled cutting (parameterized).

- E-stop & interlocks: Emergency stop + safety interlock readiness (e.g., access door/cover protection, depending on configuration).

- Metal contamination response: Support for upstream magnet separation; optional metal detection solutions can be discussed for high-risk streams.

Maintenance & Serviceability Details

Practical design choices that keep downtime low.

- Knife change method: Service-access design for faster knife rotation/replacement (final method depends on model).

- Knife steel options: D2 / SKD-11 options available based on wear expectation and budget.

- Screen change: Screen configuration and replacement method available for controlled output size.

- Lubrication points: Clear lubrication points and maintenance checklist support for routine servicing.

Showcase

Bulky rigid plastics are easier to recycle after efficient shredding and volume reduction.

Frequently Asked Questions

What materials can a rigid plastics shredder machine process?

How do I control the output size?

How does the machine reduce jam and overload risk?

Can it be integrated into a washing and pelletizing line?

Warranty & Inquiry

Share your material and capacity requirements—we will respond with a configuration and quotation.