Standard Plastic Granulators

High-performance size reduction machinery designed for efficiency. Convert plastic bottles, films, and containers into uniform granules ready for reprocessing.

Why Choose Our Granulators?

Engineered for durability and precision, our granulators are the workhorse of any plastic recycling line.

Precision Cutting

Equipped with durable SKD11 steel blades in a V-shape or double-scissor arrangement for clean, uniform cuts.

High Throughput

Efficient rotor design minimizes energy consumption while maximizing output capacity up to 2500 kg/h.

Easy Maintenance

Hydraulic-assisted access to the cutting chamber makes blade changes and screen cleaning effortless.

Robust & Safe

Heavy-duty steel construction with integrated safety switches and overload protection for safe operation.

Detailed Features

Deep dive into the components that make our granulators superior.

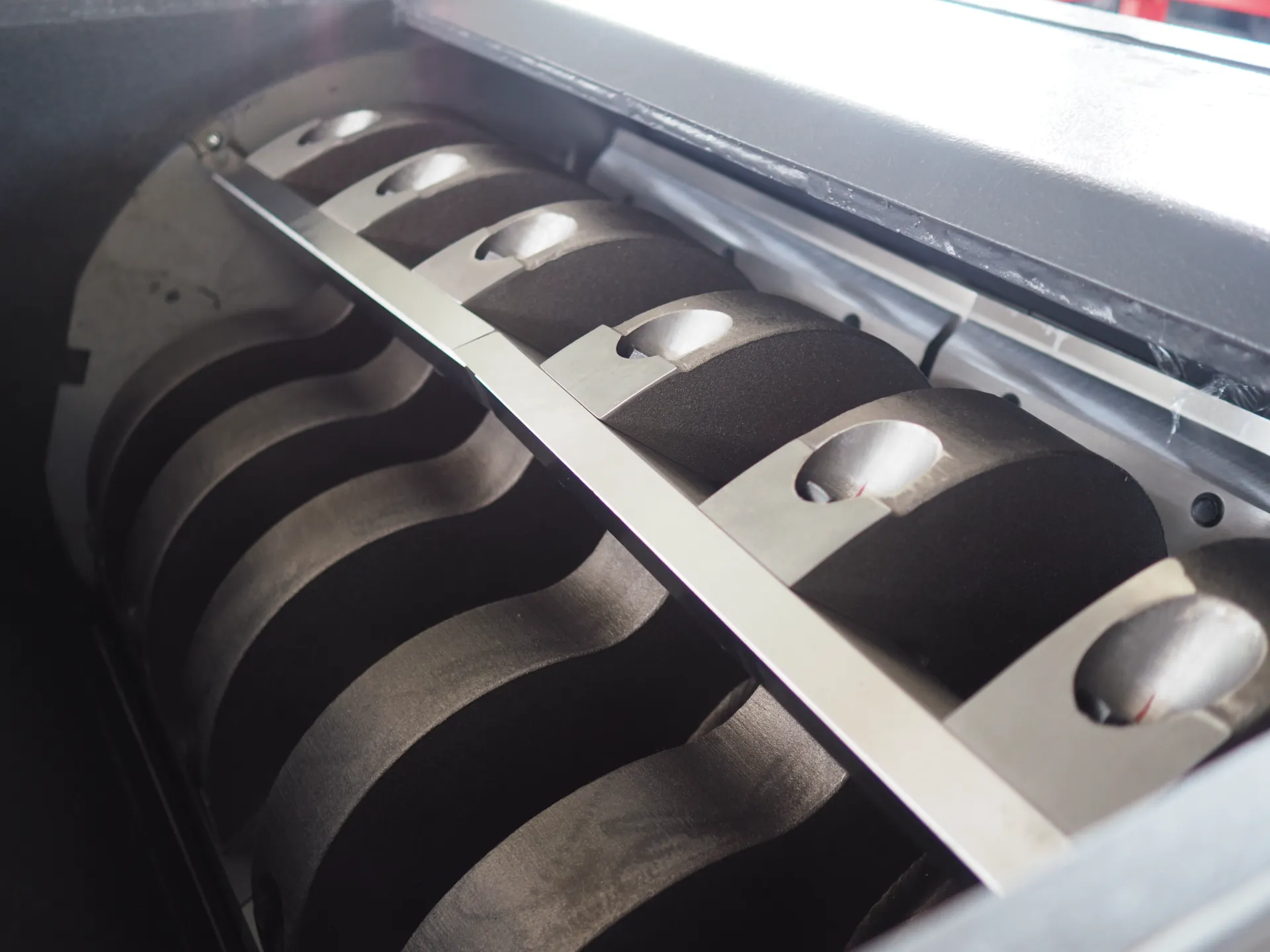

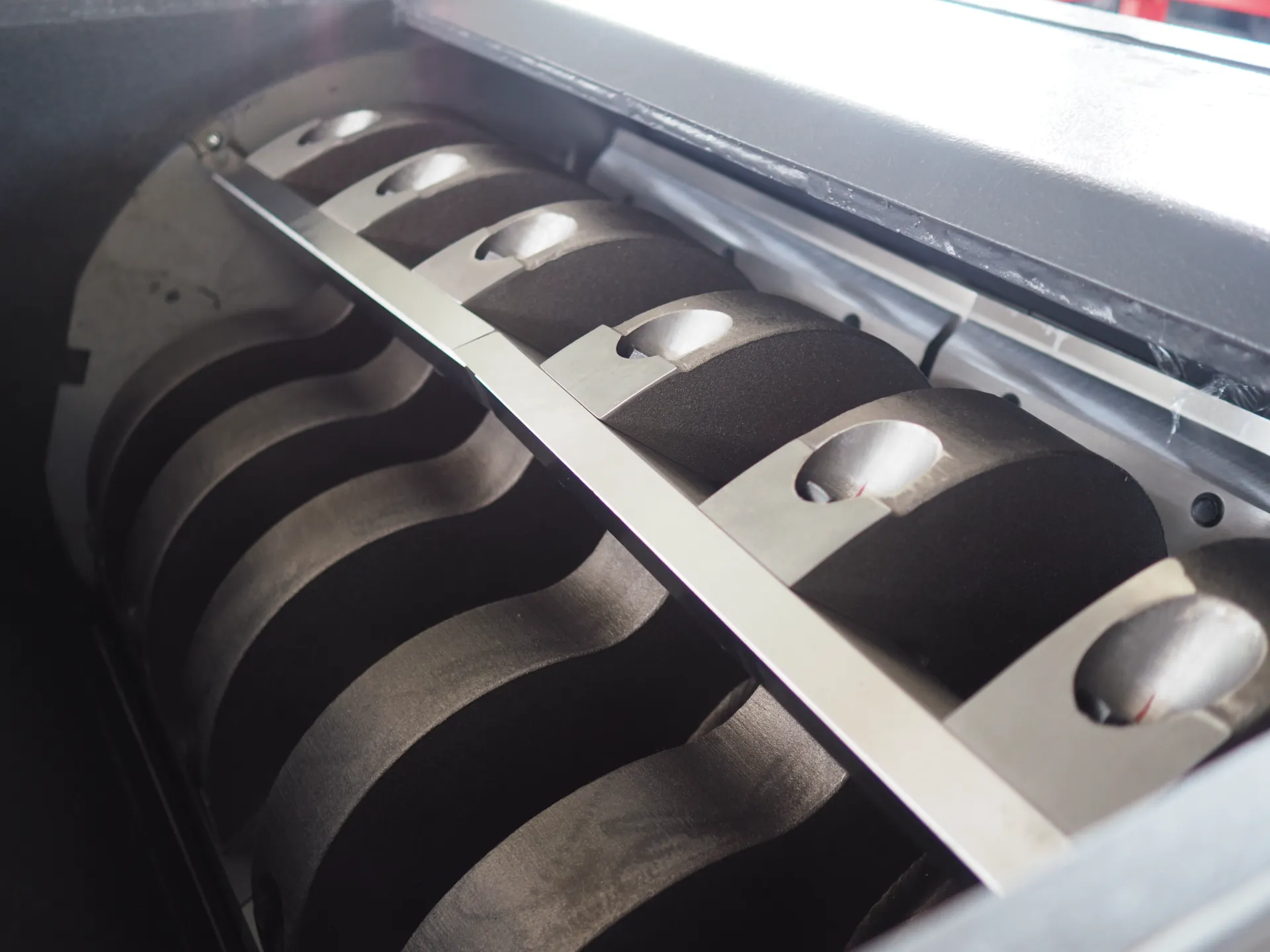

Open Rotor Design

Our open rotor design allows for significant airflow through the cutting chamber. This "cool cutting" action prevents plastics from melting or sticking, making it ideal for processing heat-sensitive materials like thin films or PET bottles.

Heavy-Duty SKD11 Blades

We use only premium SKD11 steel for our rotating and stationary knives. This material offers exceptional wear resistance and toughness, ensuring long service life even when processing abrasive or contaminated plastics.

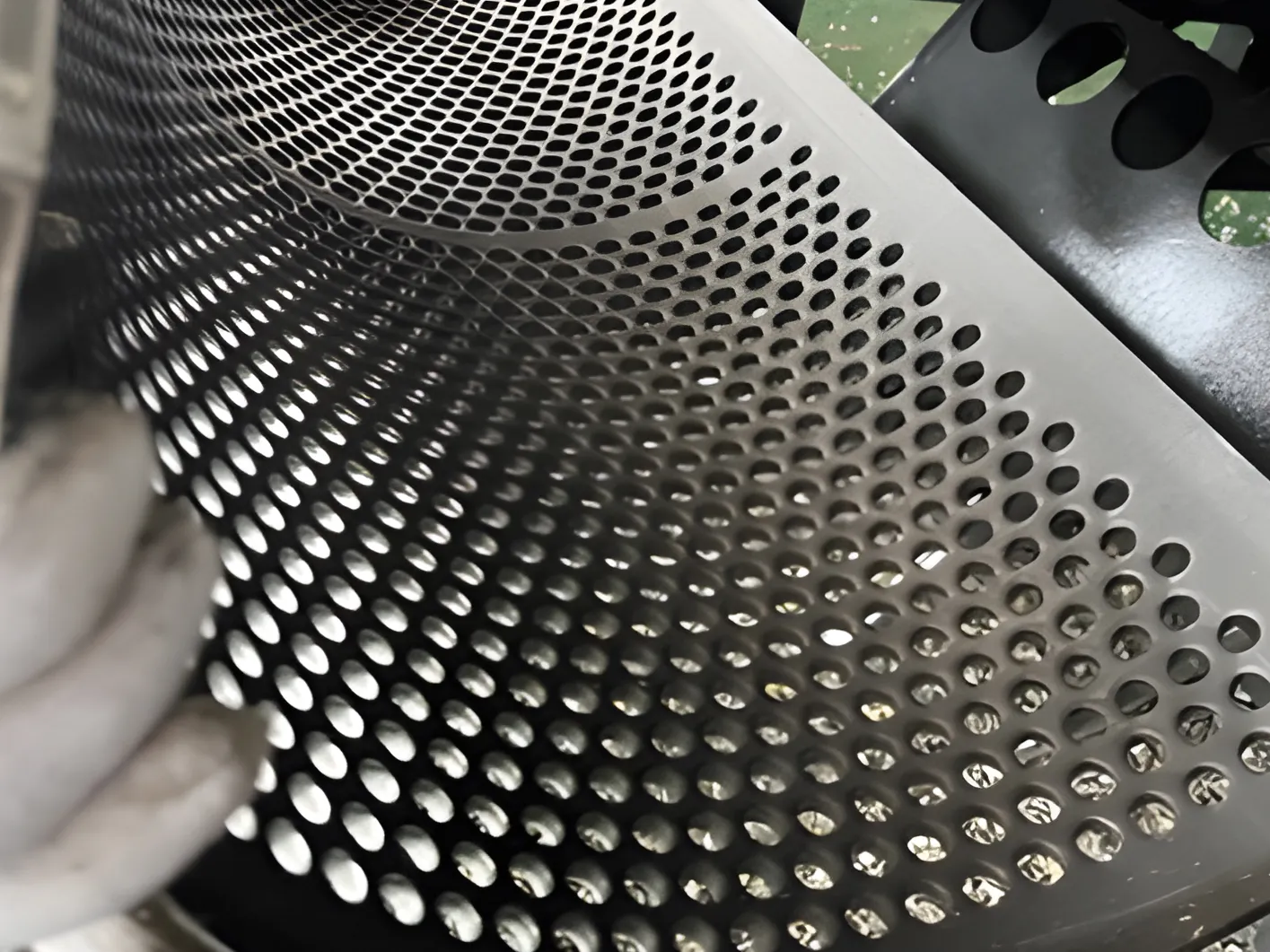

Customizable Screen Filters

Achieve the exact particle size you need. Our interchangeable screen filters range from 10mm to 100mm. The drop-down screen cradle facilitates quick changeovers between different recycling jobs.

See It In Action

Watch our plastic granulator easily process rigid plastics and films.

Technical Specifications

Select the right model for your capacity requirements.

| Model | Rotor Diameter | Motor Power | Rotating Speed | Blade Material | Capacity (kg/h) |

|---|---|---|---|---|---|

| RTM-500 | 500 mm | 45 kW | 550 rpm | SKD11 | 500 - 800 |

| RTM-600 | 600 mm | 55 kW | 500 rpm | SKD11 | 800 - 1500 |

| RTM-700 | 700 mm | 90 kW | 428 rpm | SKD11 | 1500 - 2000 |

| RTM-800 | 800 mm | 110 kW | 370 rpm | SKD11 | 2000 - 2500 |

Frequently Asked Questions

What materials can this granulator process?

How often do the blades need sharpening?

Is wet granulation possible?

Get Your Customized Solution

Fill out the form below to get a quick quote and layout design.