Agricultural Film Washing & Recycling Machine

Transform dirty, soil-rich agricultural films into high-value clean pellets. Our comprehensive washing line handles high contamination with ease.

Why Choose Our Agri-Film Recycling Line?

Engineered to tackle sand, soil, and organic matter found in agricultural waste.

Intensive Washing

Multi-stage friction and hot washing effectively remove stubborn soil, pesticides, and adhesive residues.

High & Low Density Handling

Separation tanks efficiently isolate floating PE films from sinking dirt, rocks, and metals.

Efficient Drying

Combined centrifugal and squeeze drying reduces moisture content to <3%, ready for direct pelletizing.

Robust Shredding

Heavy-duty shredders designed to handle tangled mulching films and bales without jamming.

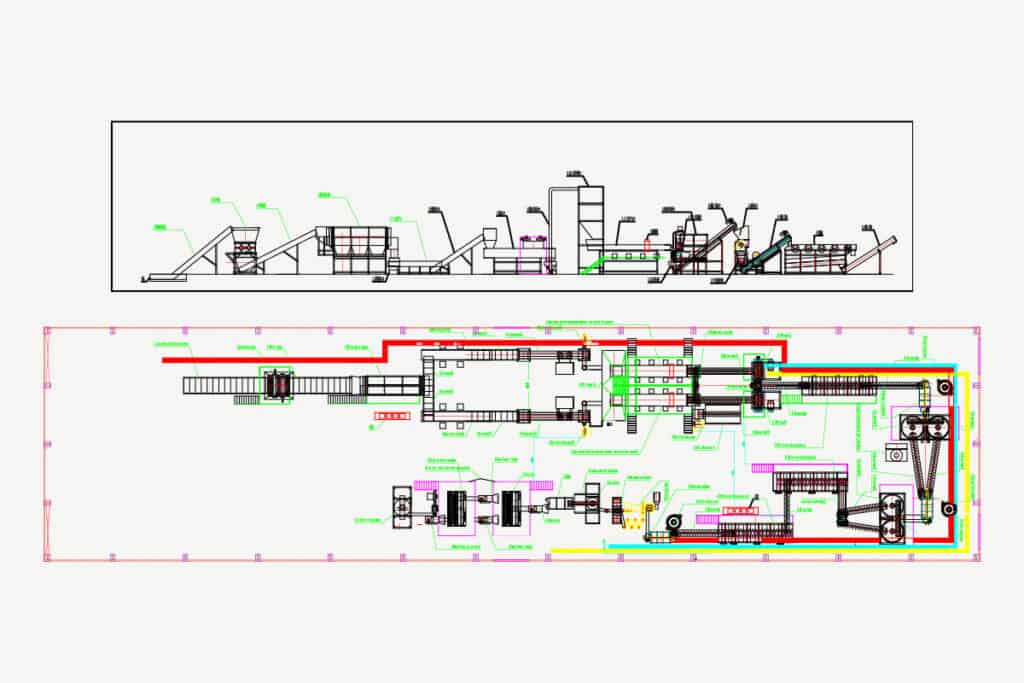

Process: From Dirty Film to Clean Pellets

A specialized workflow for high-contamination agricultural plastics.

1. Shredding

Cutting compacted bales and long films into small pieces.

2. Friction Wash

High-speed scrubbing to remove over 90% of sand and soil.

3. Sink-Float Tank

Separating plastic from heavy contaminants using density.

4. Squeeze Drying

dewatering flakes to ensure low moisture for extrusion.

5. Pelletizing

Melting and filtering to create uniform, reusable pellets.

Technical Specifications

Customizable capacities to meet your recycling plant's demands.

Standard Line Parameters

We offer solutions from 500kg/h to 3000kg/h.

| Model | GSH-500 | GSH-600 | GSH-700 | GSH-800 |

|---|---|---|---|---|

| Rotating speed(rpm/min) | 550 | 500 | 428 | 370 |

| Rotary diameter(mm) | Φ500 | Φ600 | Φ700 | Φ800 |

| Main motor power | 45kW | 55kW | 90kW | 110kW |

| Knife material | SKD11 | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 500-800 | 800-1500 | 1500-2000 | 2000-2500 |

See The Machine In Action

Watch our agricultural film recycling machine handle dirty input material.

Client Success Stories

Trusted by agricultural recyclers to turn waste into profit.

"Our input material is very dirty mulch film. Rumtoo's line handles the sand and soil incredibly well. The output quality is consistently high."

"The robust shredder and efficient washing system have doubled our processing capacity. Highly recommended for ag film recycling."

"We value the separation efficiency. The sink-float tank really makes a difference in the purity of our final pellets."

Frequently Asked Questions

Can this machine handle highly contaminated agricultural film?

What is the expected water consumption?

Do you offer installation support?

Get Your Custom Quote

Ready to upgrade your recycling capabilities? Contact us for a tailored solution.