Heavy Duty Single-Shaft Shredder Machine

Powerful size reduction for hard plastics: Turn solid lumps, pipes, and pallets into uniform particles.

Why Choose Our Single-Shaft Shredder?

Engineered for efficiency, low maintenance, and precise material control.

Uniform Particle Size

Equipped with a screen sieve to ensure consistent output size, unlike double-shaft shredders which produce random strips.

Smart Hydraulic Ram

An automated hydraulic pusher forces material against the rotor, maximizing throughput without jamming.

Lower Maintenance

Fewer blades and a simpler drive mechanism mean reduced spare parts cost and easier blade replacement.

High Efficiency

Optimized rotor geometry and high-speed operation ensure rapid processing of wide range of materials.

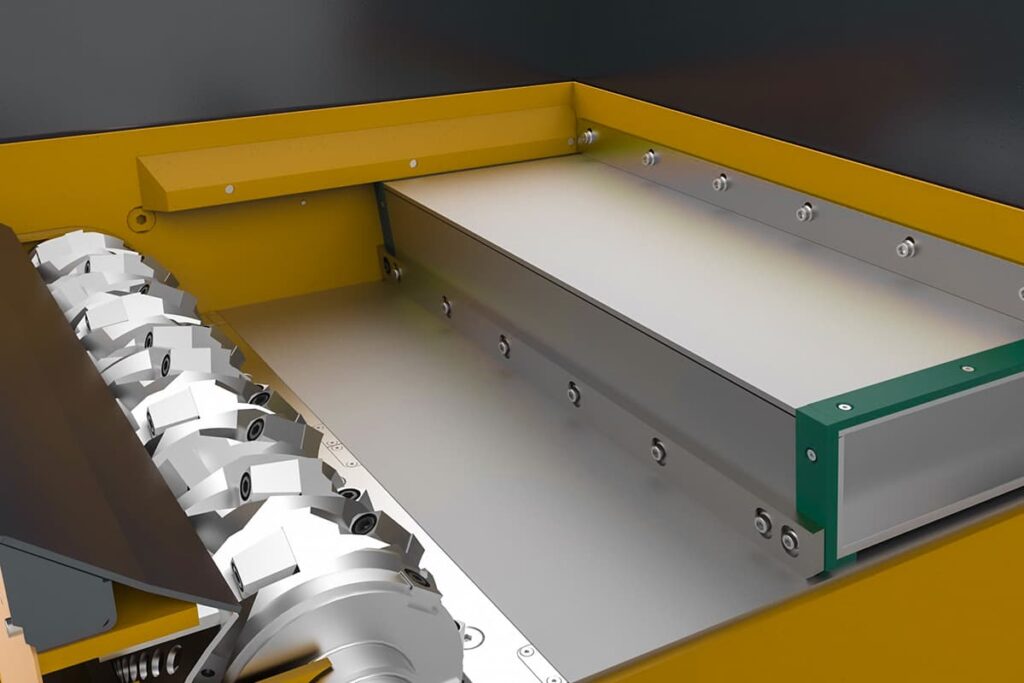

Key Components & Working Principle

Robust engineering designed to handle tough materials.

How It Works

Material falls into the hopper and is pushed by a hydraulic ram against a spinning rotor. The rotor is fitted with cutting blades that shear the plastic against a fixed counter-knife. Once the material is small enough, it passes through a screen at the bottom. Pieces that are too large are swept back up for re-shredding.

- Rotor & Blades: High-wear resistant alloy steel for long sharpness.

- Hydraulic Pusher: Smart load-sensing to prevent overloading.

- Screen: Interchangeable mesh sizes (20mm-100mm) to control output.

Single-Shaft vs. Double-Shaft

Which shredder is right for your application?

While both machines reduce material size, they serve different purposes:

Single-Shaft Shredder

Best for: Solid, thick, or hard materials (Purging lumps, runners, pellets, thick pipes, wood, paper rolls).

Pros: Controlled output size (screen), high processing speed for specific materials.

Double-Shaft Shredder

Best for: Hollow, voluminous, or lightweight materials (Films, drums, tires, electronics).

Pros: High torque for shearing, no hydraulic pusher needed, but random output size.

Technical Specifications

Standard Models

| Model | DS-600 | DS-800 | DS-1000 | DS-1200 |

|---|---|---|---|---|

| Capacity(kg/h) | 30kW | 45kW | 2*37kW | 2*45kW |

| Hydraulic motor power | 4kW | 4kW | 5.5kW | 5.5kW |

| Knife material | SKD11 | SKD11 | SKD11 | SKD11 |

| Main motor power | Φ400 | Φ400 | Φ450 | Φ500 |

| Rotary diameter(mm) | 85 | 85 | 80 | 70 |

| Rotating speed(rpm/min) | 400-600 | 600-800 | 800-1200 | 1500-2000 |

Machine Showcase

See the robust build quality and operation.

Trusted by Plastic Recyclers

"The single shaft shredder handles our purge lumps without any issue. The hydraulic ram is very efficient."

"Blade replacement is straightforward, and the output size is perfect for our extruder feed."

"Solid machine. We process heavy HDPE pipes and it cuts through them smoothly."

Frequently Asked Questions

What materials can a single-shaft shredder process?

How do I control the output size?

How often do blades need changing?

Get A Quote

Tell us your material and capacity needs, and we'll recommend the right model.