Trommel para el reciclaje de botellas de PET: El héroe anónimo de la producción de escamas puras

En el vertiginoso mundo del reciclado de plásticos, la producción constante y de alta calidad es primordial. Aunque la velocidad suele ser el centro de atención, son los procesos meticulosos y constantes los que realmente definen la eficacia y la rentabilidad de una línea de reciclaje de botellas de PET. El Trommel es un separador de tamiz rotativo robusto y fiable que ha demostrado su eficacia una y otra vez a la hora de eliminar los pequeños contaminantes problemáticos del flujo de reciclado.

En Rumtoo, entendemos que el camino hacia unos copos de PET prístinos comienza con una separación inicial eficaz. Nuestro Trommel, diseñado por expertos, es la solución más sencilla y potente para las plantas de reciclaje de plástico y las instalaciones de recuperación de materiales (MRF) a gran escala que manipulan residuos municipales, garantizando la protección de la maquinaria de procesamiento posterior y la máxima calidad del producto final.

La excelencia del trómel: el principio de funcionamiento

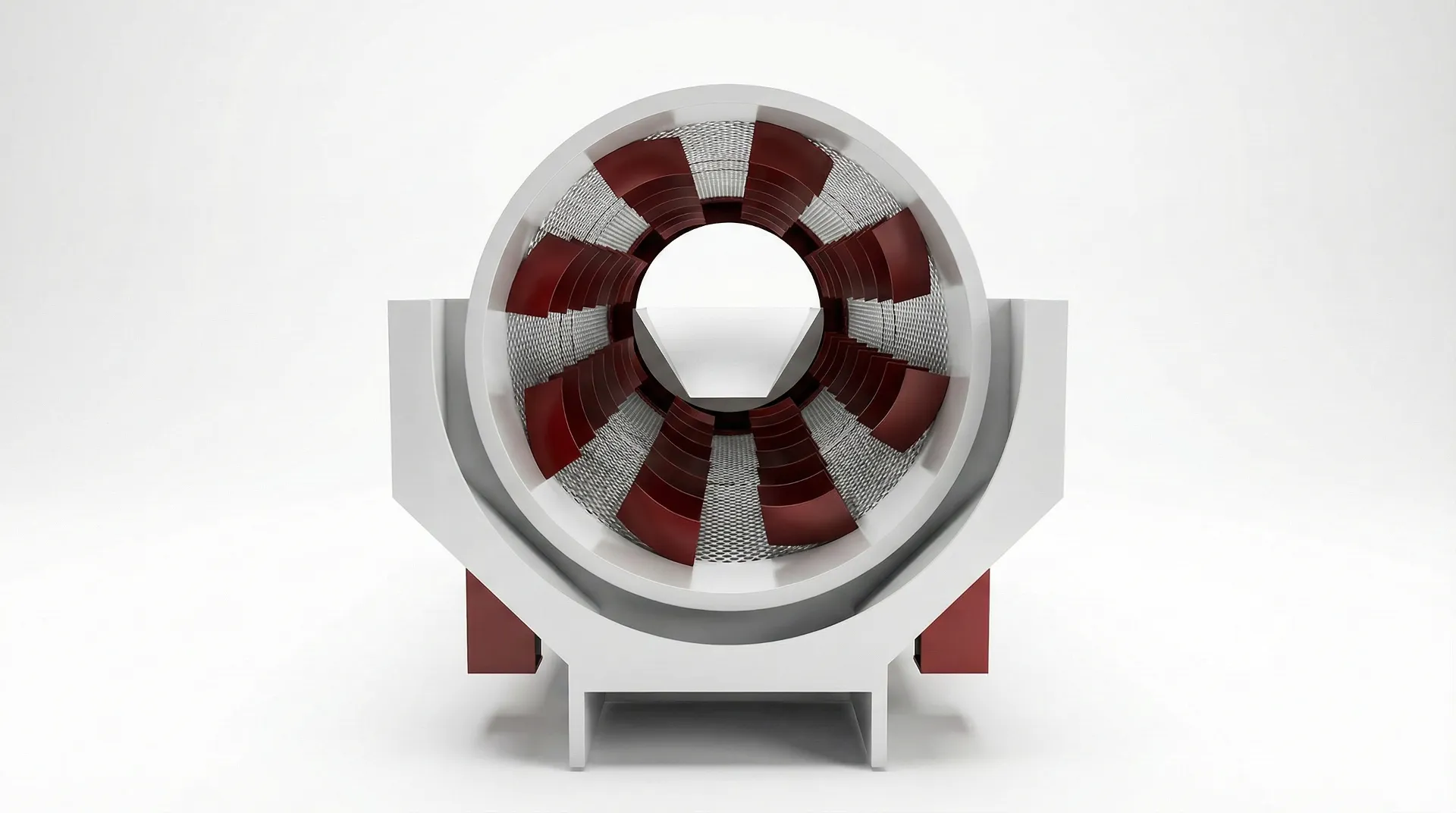

La genialidad del Trommel reside en su elegante sencillez y en su funcionamiento continuo y estable. Su núcleo es un gran túnel inclinado de malla cilíndrica. Este tambor gira a un ritmo lento y controlado, normalmente entre 6 y 10 RPM.

Cuando las botellas de PET embaladas se introducen en el extremo superior del trómel, comienza el viaje. El interior de nuestros trómeles está equipado con deflectores especialmente diseñados. A medida que el tambor gira, estos deflectores levantan y voltean suavemente las botellas. Esta agitación constante cumple una doble función: rompe eficazmente los grumos de material y guía la materia prima hacia adelante por la ligera pendiente.

Mientras las botellas de PET enteras continúan su viaje a través del cilindro, los materiales más pequeños y no deseados caen a través de las perforaciones de tamaño preciso de la malla. Estos contaminantes, como tapones de botella sueltos, vidrios rotos, piedras, tierra y otros residuos, se recogen en una tolva o en una cinta transportadora inferior, con lo que se eliminan del flujo principal de reciclado. Las botellas de PET más grandes, que son demasiado grandes para pasar a través del tamiz, se descargan en el extremo inferior, listas para la siguiente fase del proceso de reciclado, como la trituración o la granulación.

Características y ventajas clave para su línea de reciclado de PET

- Protege los equipos aguas abajo: Al eliminar los contaminantes duros y abrasivos como el vidrio y las piedras en una fase temprana, nuestro trómel reduce significativamente el desgaste de sus trituradoras y granuladoras.

- Mejora la calidad del producto final: Un flujo de entrada más limpio conduce naturalmente a un producto final de mayor calidad, produciendo escamas de PET más puras que alcanzan un precio más alto.

- Alta eficiencia, bajo mantenimiento: La rotación lenta y continua y su robusta construcción garantizan un proceso de separación muy eficaz con un consumo de energía mínimo y un mantenimiento sencillo.

- Aplicación versátil: Ideal para botellas de PET y muy eficaz para clasificar residuos sólidos urbanos (RSU), residuos de construcción y demolición (RCD) y compost.

- Adaptable a sus necesidades: Ofrecemos la personalización de parámetros clave para garantizar que nuestro trómel se integre a la perfección en su configuración actual.

Especificaciones técnicas

| Especificación | Detalles |

|---|---|

| Potencia del motor principal | 11KW x 2 |

| Potencia del motor del transportador de banda | 3KW x 2 |

| Longitud del trómel | 1200 mm (personalizable según sus necesidades) |

| Diámetro del Trommel | ⌀2000mm (Adaptable a sus necesidades) |

| Ángulo de inclinación | 3 grados |

| Velocidad de rotación del trommel | 6 RPM (Ajustable con control de frecuencia) |

| Anchura efectiva de la cinta | 1400 mm |

| Diámetro del rodillo | ⌀250mm |

Funciones adicionales para mejorar el rendimiento

Nuestro compromiso con la excelencia significa que equipamos nuestros trómeles con características que mejoran su rendimiento y longevidad. Todos nuestros modelos vienen con cepillos automáticos que limpian continuamente el tamiz de malla, evitando obstrucciones y garantizando una eficacia de separación constante. Ofrecemos diseños con tracción a las dos y a las cuatro ruedas para adaptarse a diferentes requisitos de carga. Además, nuestros trómeles están equipados con controles de frecuencia y sincronización, Permite ajustar con precisión la velocidad de rotación para adaptarla a las características específicas del material de entrada.

Una inversión inteligente en pureza y rentabilidad

En el competitivo panorama del reciclaje de PET, el Trommel es un componente vital para el éxito de cualquier operación. Puede que sea una máquina lenta, pero su capacidad para superar los retos que pueden dificultar el uso de maquinaria más rápida y compleja no tiene parangón. Al garantizar un flujo de material más limpio y homogéneo, el Trommel Rumtoo es un activo inestimable, que ofrece un medio fiable, eficaz y rentable de separación de materiales.

Todas nuestras máquinas de reciclaje tienen una garantía limitada de 1 año para su tranquilidad.

CONSULTAS

¿Está preparado para mejorar la pureza y eficacia de su línea de reciclado de botellas de PET? Para obtener los últimos precios y plazos de entrega, envíenos un mensaje. Nuestro equipo de expertos está a su disposición para ayudarle a seleccionar y personalizar el tromel perfecto para sus necesidades.