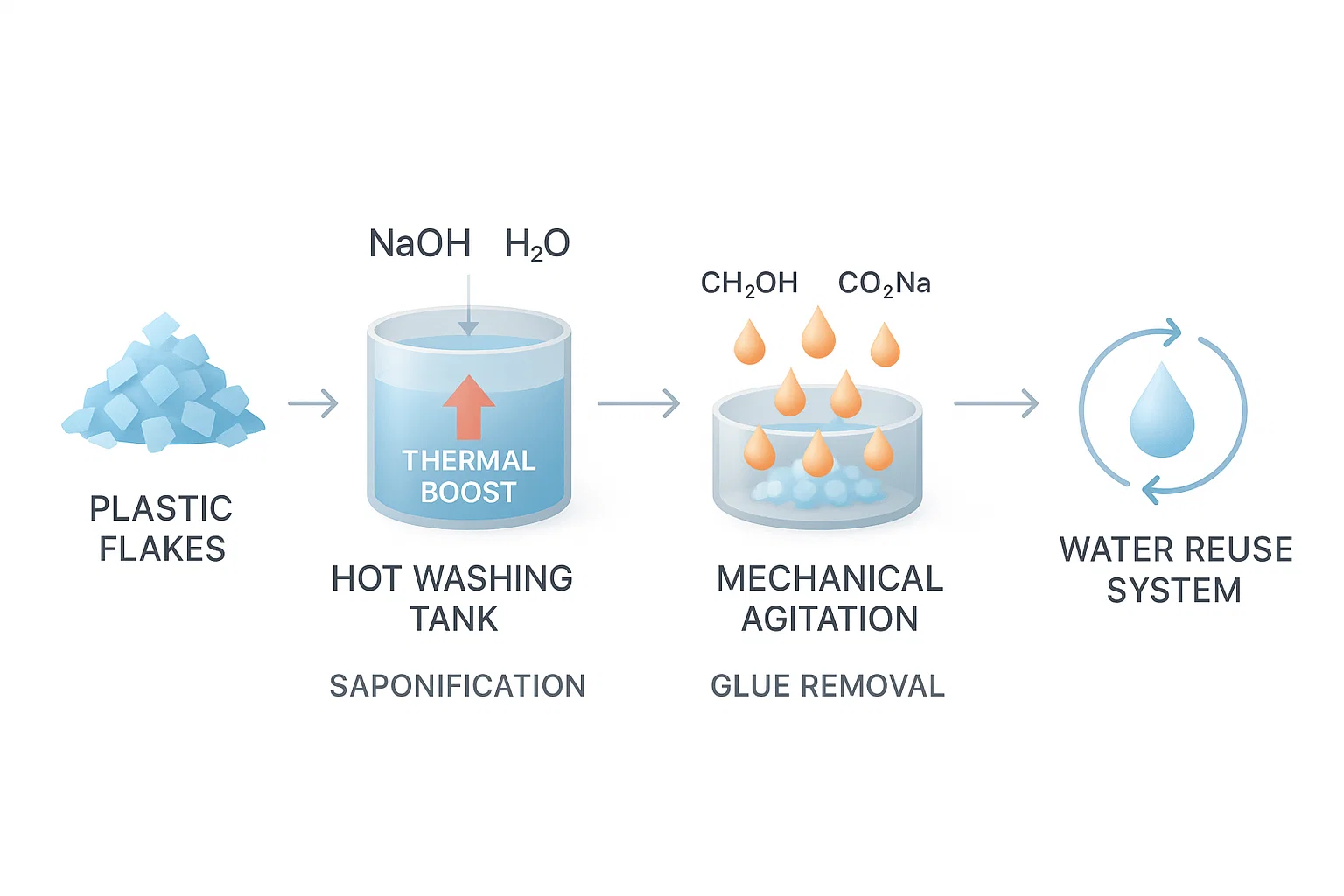

In PET bottle recycling, one of the most critical steps is the hot washing process, where high-temperature alkaline water is used to clean plastic flakes. This method effectively removes stubborn contaminants such as oil, grease, and label glue through a combination of chemical, thermal, and mechanical actions. Below is a detailed explanation of how this system works and its advantages.

Chemical Mechanisms

1. Saponification of Oils and Grease

Alkaline water, typically composed of caustic agents like sodium hydroxide or potassium hydroxide, has a high pH level (above 7). This creates an ideal environment for saponification, a chemical reaction where fats and oils are converted into soap-like, water-soluble compounds. These emulsified residues are much easier to rinse away, effectively removing oily contaminants from the PET surfaces.

2. Adhesive and Glue Removal

The caustic nature of the alkaline solution also breaks down glues and adhesives used for bottle labels. It disrupts the chemical bonds within these sticky substances, loosening them from the plastic surface. To further enhance this effect, surfactants are added. These reduce surface tension, improving the spread and penetration of the solution and facilitating the detachment of stubborn glue residues.

Physical and Thermal Effects

3. High Temperature Accelerates Cleaning

Elevated water temperatures significantly boost the reaction rate of saponification and adhesive breakdown. Heat softens glues and loosens hardened contaminants, making them easier to remove. The thermal energy complements the chemical action for faster and more efficient cleaning.

4. Mechanical Agitation for Deep Cleaning

Hot washing systems often incorporate mechanical agitation through rotary paddles or screw augers. This agitation causes PET flakes to rub against each other, producing friction that physically scrubs off residues like mud, oil, and glue. The combined effect of heat, chemistry, and friction ensures a more thorough cleaning process.

Additional Benefits

5. Contamination Control

The high temperature and caustic environment of the washing process also help eliminate biological contaminants like bacteria Und mold, improving the sanitary quality of the recycled flakes. This is especially important when recycled PET (rPET) is intended for food-grade or hygiene-sensitive applications.

6. Water Recycling and Efficiency

Modern hot washing systems are designed with integrated water treatment and recycling modules, allowing for up to 80% reuse of hot alkaline water. This not only reduces operating costs and water consumption but also maintains consistent cleaning performance by stabilizing temperature and chemical concentration.

Advantages of the Hot Washing System

- Thorough Cleaning: Effectively removes oil, grease, glue, and labels from PET flakes.

- Enhanced Recycling Efficiency: Produces higher-quality recycled PET suitable for various applications.

- Customizable Setup: Washing conditions (chemical concentration, temperature, and duration) can be tailored to different contamination levels.

- Environmentally Friendly: Incorporates water reuse systems, reducing waste and resource consumption.

Abschluss

The use of high-temperature alkaline water in PET bottle recycling plays a vital role in achieving clean, high-quality plastic flakes. Through a synergy of chemical saponification, thermal softening, and mechanical agitation, this process ensures that contaminants are thoroughly removed. The result is a more efficient recycling workflow and a superior end product suitable for reuse in a wide range of applications.