Dehydration is a critical stage in any Waschanlage für PET-Flaschen, directly influencing the quality of the recycled PET flakes. Most modern systems adopt a two-stage approach—mechanical centrifugation followed by hot air drying—to efficiently remove moisture. This combination ensures energy-efficient drying, high material purity, and optimal readiness for further processing, such as pelletising or fibre production.

For a complete overview of the recycling process, visit our PET bottle recycling machine page.

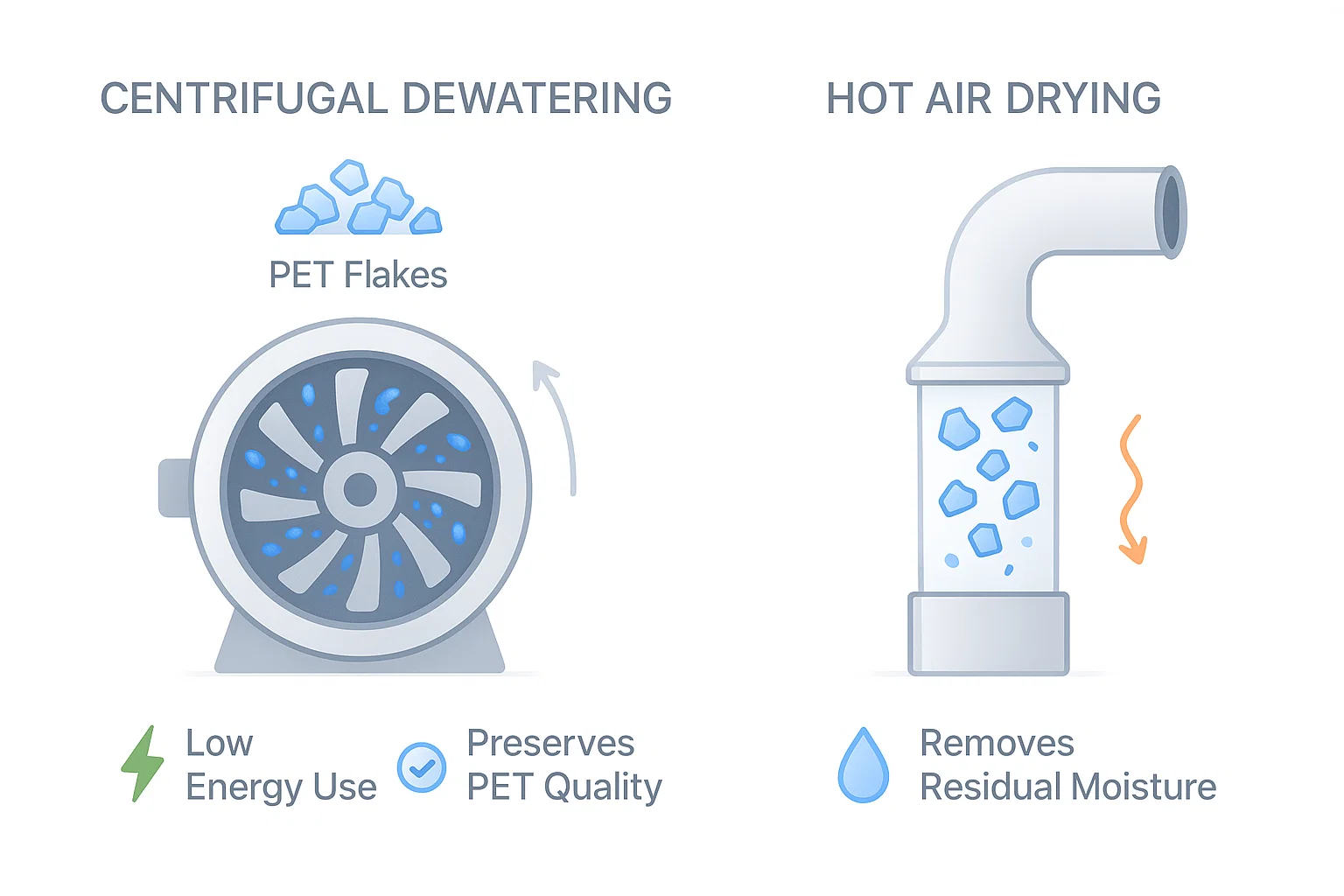

Stage 1: Mechanical Centrifugation (Centrifugal Dewatering)

The initial stage of dehydration involves a centrifugal dewatering machine. Operating on the principle of high-speed spinning, it generates centrifugal force to physically expel water from PET flakes. This stage delivers several key advantages:

- Exceptional Moisture Reduction: Capable of reducing moisture content to minimal levels, which is essential to prevent defects such as brittleness or bubble formation in the final recycled products.

- Preservation of Material Quality: As this process uses mechanical force rather than heat, it prevents thermal degradation, maintaining the PET’s clarity, tensile strength, and structural integrity.

- Energy Efficiency: Mechanical dewatering requires significantly less energy compared to thermal alternatives, thereby lowering both operating costs and carbon footprint.

- High Processing Capacity: These systems can continuously handle large volumes of PET flakes, ideal for industrial-scale recycling operations.

- Contamination Prevention: As a closed system, it minimises the risk of airborne contaminants entering the material stream during drying.

This process effectively removes the bulk of the moisture content while maintaining the physical properties of PET flakes.

Stage 2: Hot Air Drying (Thermal Drying System)

Following mechanical dewatering, PET flakes typically retain a small amount of residual moisture. To achieve optimal dryness, a hot air drying system is used. The process generally involves the following steps:

- Vacuum Transfer: Dried flakes are transported from the centrifuge into the dryer via a vacuum system to ensure seamless and hygienic transfer.

- Hot Air Circulation: Hot air is circulated through stainless steel tubes, ensuring that the remaining moisture is evaporated evenly and thoroughly.

- Cyclone Separation: The final drying phase includes a cyclone separator, which removes fine particles and reduces flake temperature before storage or further processing.

This stage ensures the PET flakes meet the necessary moisture specifications for high-grade applications such as food-safe packaging, polyester fibre production, or extrusion.

Integrated Benefits of Combined Dehydration Technology

The synergy between mechanical and thermal drying in a Waschanlage für PET-Flaschen offers numerous operational and quality-related benefits:

- Optimised Drying Efficiency: Mechanical drying quickly removes the majority of water with minimal energy use. The subsequent thermal stage eliminates residual moisture to meet industry standards.

- Consistent Flake Quality: By minimising thermal exposure early on, PET properties are preserved, and final drying ensures a contaminant-free, fully dry product.

- Energieeinsparung: Starting with energy-efficient centrifugation reduces the workload and energy requirements of the thermal dryer, resulting in lower overall consumption.

- Uninterrupted Workflow: This integrated approach supports high-throughput, continuous operation with minimal downtime or bottlenecks.

Abschluss

In conclusion, modern Waschanlagen für PET-Flaschen utilise a dual-stage dehydration process combining centrifugal dewatering Und hot air drying. This method not only enhances drying performance but also ensures the production of high-quality, contaminant-free PET flakes ready for reuse. The combination significantly improves energy efficiency, protects material integrity, and supports seamless downstream processing.

For more insights into PET recycling technology and system design, explore our dedicated PET bottle recycling machine page.