Our company specializes in providing an efficient and sustainable solution for plastic film recycling. We understand the importance of maintaining a healthy environment while also meeting the growing demand for plastic pellets. Our complete plastic film washing line is designed to handle polypropylene (PP), polyethylene (PE), and a wide range of other plastic films. Using state-of-the-art technology, our fully automated plastic film washing and pelletizing line consists of a series of plastic recycling machines that are strategically arranged to optimize efficiency and minimize waste.

In addition to our standard Plastic Film Washing Line, which have input capacities ranging from 500kg/h to 3000kg/h, we also offer custom setups for clients with larger recycling needs. These custom setups utilize additional machinery and increased capacity, ensuring that we can meet the unique demands of each of our clients.

Our turnkey solution is not only effective in recycling loose or baled plastic film into plastic pellets, but it also helps to reduce the carbon footprint of plastic waste. By recycling plastic film instead of sending it to landfill sites, we are able to contribute to a healthier environment for future generations.

We take pride in our commitment to sustainability and excellence in customer service. Our team of experts is always available to help you find the right solution for your plastic film recycling needs. Contact us today to learn more about our turnkey solution and how we can help you make a positive impact on the environment while also achieving healthy margins.

Main Technical Parameter

| Model | GSH-500 | GSH-600 | GSH-700 | GSH-800 |

|---|---|---|---|---|

| Rotating speed(rpm/min) | 550 | 500 | 428 | 370 |

| Rotary diameter(mm) | Φ500 | Φ600 | Φ700 | Φ800 |

| Main motor power | 45kW | 55kW | 90kW | 110kW |

| Knife material | SKD11 | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 500-800 | 800-1500 | 1500-2000 | 2000-2500 |

We are pleased to offer you a free solution design service. Our team of experts will design the most suitable plastic film cleaning line solution for you based on your needs and requirements. Please contact us for more information and to start discussing your project.

Working Principle

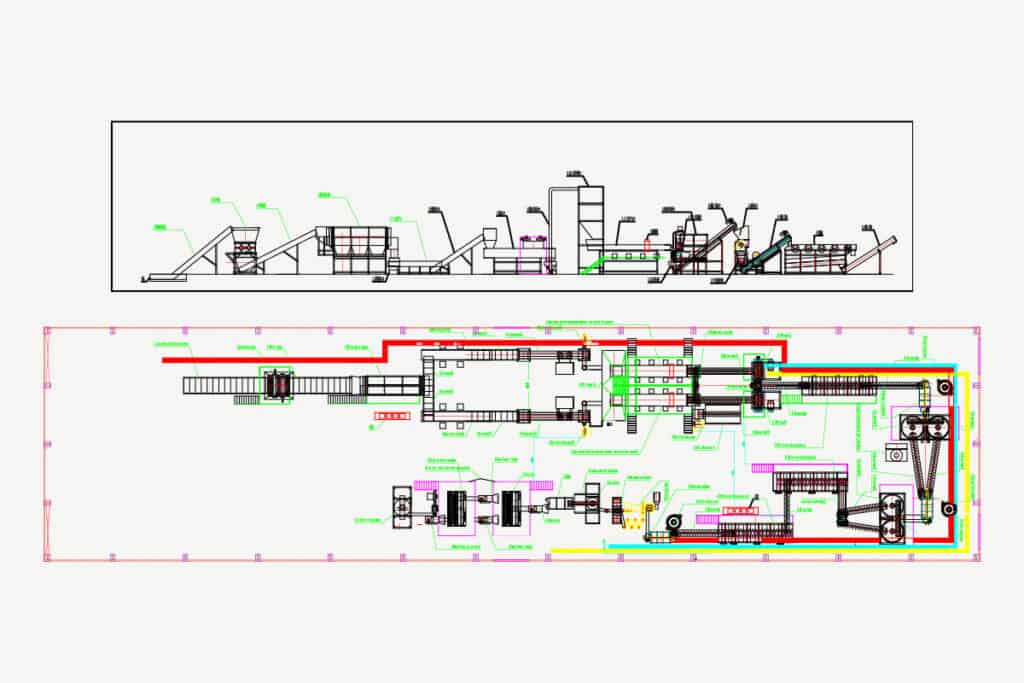

The entire plastic film washing line is controlled via a central electric control panel and cabinet. Each piece of equipment is connected using conveyors.

- Plastic Shredder Machine:

As long pieces of plastic film easily tangle (imagine saran wrap) and clogs conveyors and rotary-based machines, the first step is to cut the plastic film into smaller pieces using a plastic shredder machine. The resulting plastic pieces from the plastic shredder is around 1-5 inches. - Plastic Granulator:

The plastic granulator cuts the plastic film into even smaller pieces approximately 10-20mm in size. With water constantly injected into the cutting chamber, our wet granulation process also “pre-treats”and partially cleans the plastic film before moving onto the next machine. - Friction Washer:

A high-power washing machine, our cold water friction washers spins at nearly 1,000 rotations per minute. As the PP /

PE films enters the friction washer, the plastic film rubs against each other at high speeds getting rid of hard to remove contamination. At the same time, any paper and cardboard is broken down into fibers and removed. While one friction washer isstandard, various washing plants have requested a secondary friction washer to ensure thorough cleanliness. - Sink Float Separation Tank:

Using water as a medium, materials that float are separated from materials that sink. In the case of plastic film recycling, PP and PE films will float while heavier contamination such as dirt, sand, glass, metals, other plastics will sink. A screw conveyor at the bottom of the sink float separation tank removes the contamination. While separation is one aspect of this apparatus, a secondary function is to further clean the plastic film. - Centrifugal Dewatering Machine:

The first step in the drying process, our centrifugal dewatering machine uses centrifugal force to remove a large portion of water within the plastic film before moving forward onto the thermaldryers. As thermal dryers use heat to dehydrate water, it requires more energy consumption during operation. Hence, the use of the dewatering machine is beneficial in savings for long run operations costs. - Screw Press Dewatering Machine:

An optional piece of equipment, the screw-press dewatering machine is a more advance version of the standard dewatering machine. Instead of using centrifugal force to remove water from the plastic film, the screw press squeezes the water out via high pressure. This machine can actually take the place of both the dewatering machine and thermal dryers. - Thermal Dryer +Cyclone Separator:

The clean plastic film is vacuumed out of the dewatering machine and into the thermal dryer system where it’ ll travel down a series of stainless steel tubes mixing with hot air. The remaining moisture is dehydrated in this process which ends with a cyclone separator. The cyclone separator allows the plastic film to mix with a fresh stream of cold air which prepares it for storage into the product silo. The cyclone separator is also effective in removing fines and such dust. - Product Silo:

A storage tank for the clean, dry pieces of plastic film. - Plastic Pelletizing Machine:

The final step in plastic film recycling and maybe the most important, the clean film needs to be processed into plastic pellets before it can be used in production. To do so, we offer a specialized plastic film water ring pelletizer system that produces beautiful round plastic pellets.

Warranty

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.

[contact-form-7 id=”6647″ title=”Contact form 2″]