In today's increasingly environmentally conscious world, businesses are seeking innovative solutions to reduce their ecological footprint while simultaneously improving their bottom line. Investing in a maszyna do recyklingu plastikowych butelek, szczególnie w przypadku butelek PET, jest potężną strategią, która działa na obu frontach. Ten kompleksowy przewodnik zagłębi się w przekonujące powody, dla których maszyna do recyklingu butelek PET jest mądrą inwestycją i zapewni szczegółową, krok po kroku mapę drogową do wyboru idealnej maszyny do Twoich potrzeb operacyjnych.

Podstawowe powody, dla których warto zainwestować w maszynę do recyklingu butelek PET

Beyond mere compliance, embracing PET bottle recycling offers a multitude of tangible and intangible benefits that can significantly impact your business's success and reputation.

1. Bądź mistrzem ochrony środowiska: zmniejsz swój ślad węglowy

Najbardziej bezpośrednią i znaczącą korzyścią z recyklingu butelek PET jest ich głęboki pozytywny wpływ na środowisko. Przetwarzając wyrzucony PET, Twoja firma aktywnie przyczynia się do:

- Ochrona zasobów: Mniejsza produkcja pierwotnego PET oznacza mniejsze zużycie paliw kopalnych i mniejsze uzależnienie od zasobów nieodnawialnych.

- Mniejsza ilość odpadów składowanych na wysypiskach: Ograniczanie składowania plastikowych butelek na wysypiskach śmieci łagodzi rosnący problem zanieczyszczenia plastikiem i wydłuża okres przydatności odpadów na wysypiskach.

- Niższa emisja gazów cieplarnianych: Recykling PET wymaga znacznie mniej energii niż produkcja nowego plastiku z surowców, co prowadzi do znaczącej redukcji emisji gazów cieplarnianych.

Angażując się w widoczne stosowanie zrównoważonych praktyk, Twoja firma nie tylko realizuje globalne cele w zakresie zrównoważonego rozwoju, ale także demonstruje głębokie zaangażowanie na rzecz odpowiedzialności za środowisko, co znajduje oddźwięk wśród świadomych ekologicznie konsumentów i interesariuszy.

2. Odblokuj znaczące oszczędności kosztów: zoptymalizuj swoje operacje

Inwestycja w maszynę do recyklingu butelek PET może przynieść znaczne i trwałe oszczędności, co bezpośrednio wpłynie na wydajność operacyjną i rentowność Twojej firmy.

- Niższe koszty surowców: W przypadku przedsiębiorstw wykorzystujących PET w swoich produktach recykling pozwala na ponowne wykorzystanie plastiku, minimalizując lub nawet eliminując potrzebę zakupu nowych, pierwotnych materiałów.

- Niższe koszty gospodarowania odpadami: Przetwarzając własne odpady PET, znacznie zmniejszasz ilość odpadów trafiających na wysypiska, co przekłada się na znaczne oszczędności w opłatach za odbiór i utylizację odpadów.

Te łączne oszczędności mogą szybko zrekompensować początkową inwestycję w maszynę do recyklingu, stanowiąc wyraźną zachętę finansową do wdrożenia nowego rozwiązania.

3. Rozwijaj nowe źródła przychodów: korzystaj z gospodarki o obiegu zamkniętym

A PET bottle recycling machine isn't just an expense; it's an asset that can generate new income for your business.

- Sprzedaż przetworzonego PET: Przetworzone płatki lub granulki PET są cennym towarem na rynku recyklingu. Możesz sprzedawać te materiały innym producentom, którzy wykorzystują w swoich produktach materiały pochodzące z recyklingu, tworząc nowy i stały strumień przychodów.

- Wewnętrzna produkcja produktów: Jeśli Twoja firma produkuje towary z użyciem PET, odzyskany materiał może zostać ponownie włączony do Twojego procesu produkcyjnego, co przełoży się na bardziej cyrkularny i zrównoważony model produkcji, przy jednoczesnym obniżeniu kosztów pozyskiwania materiałów zewnętrznych.

Umiejętność przekształcania odpadów w wartościowe zasoby stanowi podstawę gospodarki o obiegu zamkniętym i zapewnia wysoki zwrot z inwestycji.

4. Zapewnij zgodność z przepisami: bądź o krok przed konkurencją

Globalny krajobraz regulacyjny dotyczący gospodarki odpadami i recyklingu stale ewoluuje i staje się coraz bardziej rygorystyczny. Proaktywne inwestowanie w wewnętrzne maszyna do recyklingu plastikowych butelek zapewnia Twojej firmie:

- Spełnia wymogi przepisów lokalnych i międzynarodowych: Uniknij potencjalnych kar pieniężnych i konsekwencji prawnych, stosując się do coraz bardziej rygorystycznych przepisów dotyczących utylizacji i recyklingu odpadów.

- Poprawia reputację firmy: Wykazując zaangażowanie w odpowiedzialną gospodarkę odpadami, pokazujesz swoją firmę jako odpowiedzialnego obywatela korporacyjnego – czynnik coraz bardziej ceniony przez konsumentów, inwestorów i partnerów.

Jeśli będziesz wyprzedzać wymagania regulacyjne, nie tylko ograniczysz ryzyko, ale także ugruntujesz swoją pozycję lidera w dziedzinie zrównoważonych praktyk.

5. Wzmocnij wizerunek marki i lojalność klientów: nawiąż kontakt ze świadomymi konsumentami

In today's market, consumers are increasingly making purchasing decisions based on a company's ethical and environmental practices.

- Lepsze postrzeganie marki: Widoczne zaangażowanie się w działania związane z recyklingiem, np. poprzez zainstalowanie własnej maszyny do recyklingu butelek PET, wzmacnia wizerunek Twojej marki, pokazując Twoją firmę jako odpowiedzialną za ochronę środowiska i myślącą przyszłościowo.

- Przyciągnij klientów świadomych ekologicznie: Zrównoważony rozwój jest silnym czynnikiem różnicującym. Twoje zaangażowanie w recykling może przyciągnąć rosnący segment konsumentów, którzy stawiają na przyjazne dla środowiska firmy.

- Wspieraj lojalność klientów: Konsumenci często czują silniejsze połączenie z markami, które są zgodne z ich wartościami. Wykazując się odpowiedzialnością za środowisko, możesz budować głębsze zaufanie i lojalność wśród swojej bazy klientów.

Te niematerialne korzyści przekładają się na większy udział w rynku i długoterminowy sukces przedsiębiorstwa.

Przewodnik krok po kroku dotyczący wyboru odpowiedniej maszyny do recyklingu butelek PET

Wybór optymalnej maszyny do recyklingu butelek PET jest kluczowy dla maksymalizacji inwestycji i zapewnienia wydajnej pracy. Ten przewodnik przeprowadzi Cię przez kluczowe kwestie.

Zrozumienie potrzeb Twojej firmy: kładzenie fundamentów

Zanim zagłębisz się w specyfikacje maszyny, niezbędne jest przeprowadzenie dokładnej oceny wymagań operacyjnych.

- Oceń swoje wymagania dotyczące wolumenu: Dokładnie określ ilość butelek PET, które Twoja firma przetwarza codziennie, co tydzień i co miesiąc. Te krytyczne dane bezpośrednio poinformują o wymaganej mocy przetwórczej Twojej maszyny.

- Oceń dostępność przestrzeni: Carefully consider the physical space available for the machine installation. Remember to account for not only the machine's footprint but also adequate room for material handling, storage of incoming bottles, and processed recycled material.

- Określ swoje założenia budżetowe: Ustal jasny budżet na tę inwestycję. Oprócz początkowej ceny zakupu uwzględnij koszty instalacji, bieżące wydatki na konserwację i koszty operacyjne, takie jak energia elektryczna i robocizna. Kompleksowy budżet zapobiegnie nieoczekiwanym obciążeniom finansowym.

Najważniejsze cechy, na które należy zwrócić uwagę: Co wyróżnia maszynę?

Gdy już poznasz swoje potrzeby, skup się na specyfikacjach technicznych, które zapewnią optymalną wydajność.

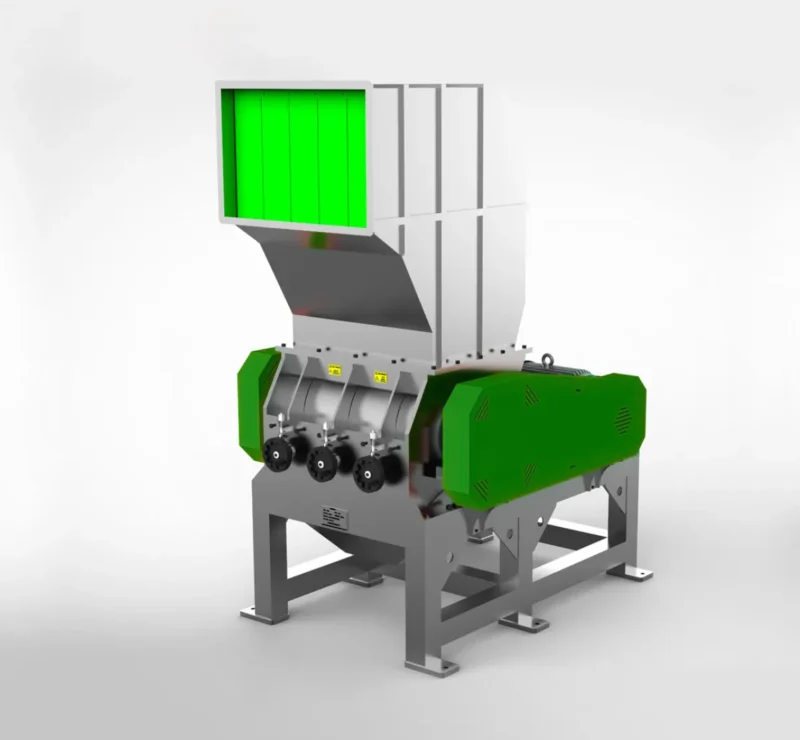

- Prędkość przetwarzania (przepustowość): Wybierz maszynę, której prędkość przetwarzania jest zgodna z Twoimi wymaganiami dotyczącymi wolumenu. Operacje o dużej objętości wymagają szybszej maszyny, aby utrzymać wydajność i uniknąć wąskich gardeł.

- Efektywność energetyczna: Nadaj priorytet maszynom zaprojektowanym pod kątem efektywności energetycznej. To nie tylko zminimalizuje Twoje koszty operacyjne w czasie, ale także jeszcze bardziej zmniejszy Twój wpływ na środowisko, zgodnie z Twoimi celami zrównoważonego rozwoju.

- Łatwość obsługi i konserwacji: Wybierz maszynę przyjazną dla użytkownika i wymagającą prostych procedur konserwacyjnych. Zapewnia to płynne codzienne działanie, zmniejsza potrzebę specjalistycznych umiejętności technicznych i minimalizuje kosztowne przestoje.

- Jakość wyników: Krytycznie oceń jakość materiału PET pochodzącego z recyklingu, który produkuje maszyna. Jeśli planujesz sprzedawać materiał pochodzący z recyklingu lub używać go we własnych produktach, musi on spełniać standardy branżowe dotyczące czystości, rozmiaru i innych specyfikacji. Wysoka jakość wyników maksymalizuje wartość materiału pochodzącego z recyklingu.

Obliczanie potencjalnego zwrotu z inwestycji (ROI): uzasadnienie inwestycji

Wysoki zwrot z inwestycji (ROI) jest kluczem do zapewnienia sobie wewnętrznego poparcia i wykazania opłacalności finansowej inwestycji.

- Porównaj koszty początkowe i oszczędności długoterminowe: Przeprowadź szczegółową analizę finansową, porównując początkowe wydatki kapitałowe z przewidywanymi długoterminowymi oszczędnościami na zakupach surowców i opłatach za zarządzanie odpadami. Często wyższy początkowy koszt bardziej wydajnej i trwałej maszyny można uzasadnić znacznymi oszczędnościami i zwiększonymi przychodami w całym okresie jej eksploatacji.

- Szacunkowy przychód z recyklingu PET: Zbadaj aktualne stawki rynkowe na płatki lub granulki PET z recyklingu. Na podstawie prognozowanej wielkości produkcji oszacuj potencjalny przychód, jaki możesz wygenerować ze sprzedaży tego cennego surowca.

- Weź pod uwagę korzyści niematerialne: Choć trudniej to bezpośrednio skwantyfikować, rozważ znaczne korzyści niematerialne. Lepszy wizerunek marki, zwiększona lojalność klientów, lepsza zgodność z przepisami i silniejsza reputacja zrównoważonej firmy mogą pośrednio przyczynić się do znacznych zysków finansowych poprzez zwiększoną sprzedaż i uniknięte kary.

Finalizowanie decyzji: podejmowanie świadomego wyboru

Ostatnie kroki obejmują należytą staranność i zapewnienie jak najlepszego partnerstwa.

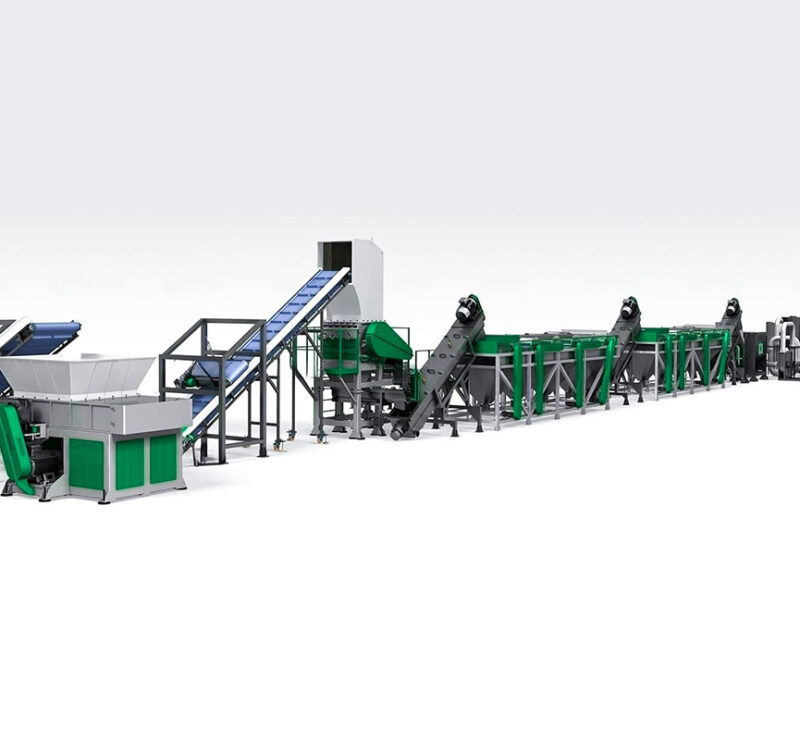

- Producenci i dostawcy badań: Dokładnie zbadaj różnych producentów i dostawców maszyny do recyklingu butelek plastikowych. Szukaj firm o sprawdzonej historii, pozytywnych opiniach klientów i reputacji niezawodnych produktów oraz doskonałej obsługi posprzedażowej.

- Poproś o szczegółowe wyceny i propozycje: Uzyskaj kompleksowe wyceny i propozycje od wielu renomowanych dostawców. Porównaj je nie tylko pod względem ceny, ale także pod względem dołączonych funkcji, gwarancji, usług instalacyjnych i bieżącego wsparcia.

- Przeprowadź wizyty na miejscu i pokazy (jeśli to możliwe): Jeśli to możliwe, umów się na wizytę w zakładach, w których maszyny, które rozważasz, są obecnie eksploatowane. Zapewnia to bezcenny wgląd z pierwszej ręki w ich wydajność, niezawodność i łatwość użytkowania w warunkach rzeczywistych.

- Priorytetowe traktowanie wsparcia posprzedażowego i szkoleń: Potwierdź, że dostawca oferuje kompleksowe wsparcie posprzedażowe, w tym pomoc techniczną, dostępność części zamiennych i programy szkoleniowe dla Twojego personelu. Jest to niezwykle ważne dla utrzymania wydajnej pracy, szybkiego rozwiązywania problemów i maksymalizacji żywotności Twojej maszyny.

Wniosek

Inwestowanie w maszyna do recyklingu plastikowych butelek for PET is more than just an operational upgrade; it's a strategic imperative for businesses aiming to enhance both their sustainability credentials and their financial profitability. By meticulously assessing your specific needs, diligently evaluating key machine features, and thoroughly calculating your potential return on investment, you can confidently select the ideal machine. This pivotal decision will not only align with your business goals but also secure a robust and rewarding return on investment, propelling your company towards a more sustainable and prosperous future.