High-Efficiency Plastic Washing Lines

Convert plastic waste into high-purity, reusable raw materials. Our PET, HDPE, and Film washing systems offer outstanding performance and dependability.

Request a QuoteWhy Choose Our Washing Lines?

Modular Design

Tailor your washing line to precisely match your input materials and production needs.

Low Energy Consumption

Efficient motors and heating systems lower operational costs and reduce environmental footprint.

Durable & Reliable

Built with premium, wear-resistant materials for extended life and consistent performance.

Superior Cleaning

Avanzada tecnología de lavado y lavado de fricción garantiza bajo contenido de humedad y escamas de alta pureza.

Nuestro Proceso de Lavado Probado

1. Desbalizado y Triturado

Los fardos se descomponen y el plástico se tritura en escamas pequeñas y uniformes.

2. Flotación y Lavado

Las escamas se lavan para eliminar contaminantes como polvo, arena y etiquetas.

3. Lavado Caliente y de Fricción

Un lavado intensivo a alta temperatura elimina pegamento y aceite, seguido de un lavado de fricción a alta velocidad.

4. Deshidratación y Secado

El secado mecánico y térmico reducen el contenido de humedad a menos de 1%.

5. Emballage

Les paillettes sèches et propres sont collectées et emballées pour réutilisation.

Fonctionnalités Avancées et Spécifications Techniques

Concasseur/Écumeur de Haute Qualité

Équipé d'un rotor en forme de V pour une réduction de taille efficace et silencieuse des plastiques rigides et des films.

Laveuse à Friction à Haute Vitesse

Les rotors fonctionnant à plus de 1 000 tr/min nettoient efficacement les matériaux pour éliminer même les contaminants les plus tenaces.

Réceptacle de Séparation par Flottaison

Sépare efficacement les polyoléfines (PP/PE) des matériaux enfoncés comme le PET, assurant une haute pureté des matériaux.

Système de Contrôle par PLC

Centralizado sistema de PLC Siemens com interface de toque para operação e monitoramento facilitados de toda a linha.

Tabela de Parâmetros Técnicos (Exemplo para PET 1000 kg/h)

| Parámetros | Valor |

|---|---|

| Modelo | PET-WASH-1000 |

| Capacidade | 1000-1200 kg/hora |

| Materiais Aplicáveis | Bottles de PET, Flakes de PET |

| Tamanho do Produto Final | 12-14 mm (personalizável) |

| Final Moisture Content | < 11% moisture content |

| PVC Content | < 100 ppm PVC content |

| Total Installed Power | Approx. 215 kW total installed power |

| Water Consumption | 1-2 m³/ton (with circulation system) |

| Footprint (L x W x H) | Approx. 90m x 8m x 6m footprint |

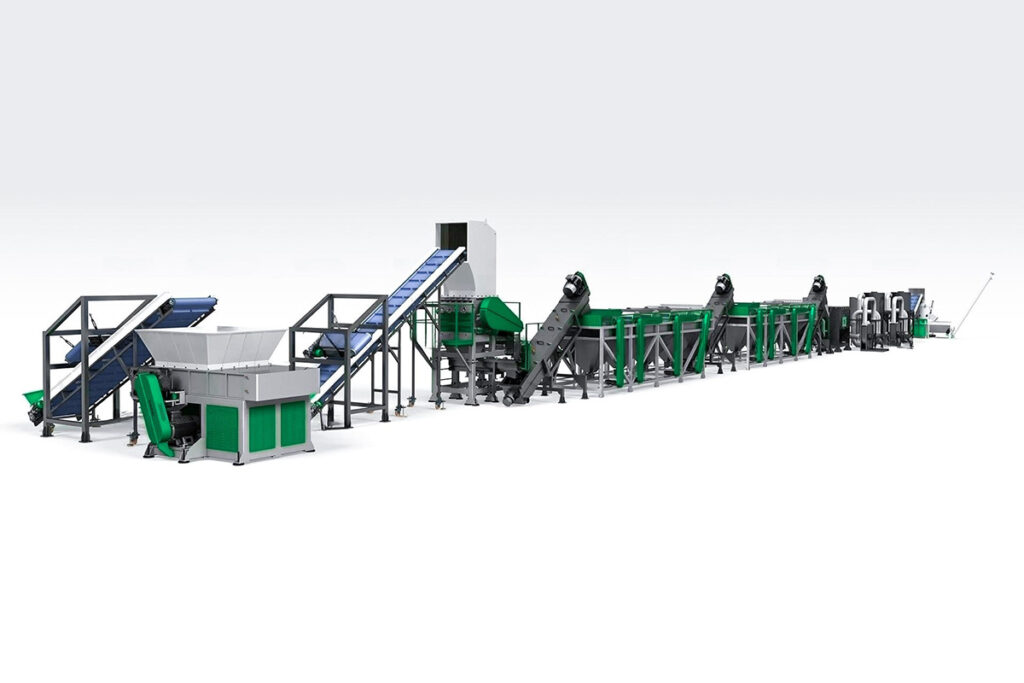

Machine Gallery & Live Operation

Foires aux Questions

What types of plastic can this line process?

This line is designed to handle a diverse range of plastics, including rigid materials such as PET (bottles) and HDPE (containers), as well as flexible plastics like LDPE/LLDPE film and PP woven bags. Each system is tailored to cater to the distinct properties of the materials being processed.

What is the final quality of the recycled flakes?

Our aim is to deliver recycled flakes of the highest purity, free from contaminants, ideal for pelletizing or direct application in manufacturing processes. For PET, we typically achieve a moisture content of less than 1% and a PVC content below 100ppm, which guarantees the flakes are suitable for producing food-grade rPET (after further processing) or premium polyester fibers.

How much space and power are required?

The space and power demands are contingent upon the processing capacity (e.g., 500 kg/h versus 3000 kg/h) and the particular components involved. A typical 1000 kg/h PET bottle washing system may necessitate around 90 meters in length and an installed power of approximately 215 kW. We supply a detailed layout and power assessment with every proposal.

Do you provide installation and training services?

Absolutely, we provide a full suite of services that include international installation, system commissioning, and operational training for your personnel. Our engineers guarantee the line operates efficiently and that your team is proficient in managing and maintaining the system to ensure peak performance.