Dobrodošli u tvrtku "Rumtoo", koja se bavi recikliranjem plastike, gdje su visokokvalitetni strojevi za recikliranje PP/PE folija naš glavni prioritet. Naši strojevi dizajnirani su s jednostavnim rukovanjem, jednostavnim održavanjem i razumnim cijenama. Naši iskusni inženjeri spremni su vam pružiti detaljne upute za uporabu, tehničku dokumentaciju i pravovremenu postprodajnu uslugu.

Istovremeno, pružamo i besplatne usluge dizajna proizvoda. Posvećeni smo prilagođavanju proizvodnih rješenja za kupce, čineći proizvodnju učinkovitijom i ekološki prihvatljivijom, čime formiramo temeljnu konkurentnost održivog razvoja i doprinosimo globalnoj uštedi energije, smanjenju emisija i zelenom gospodarskom razvoju, nastojeći stvoriti bolji život.

Naši proizvodi uključuju: linije za recikliranje plastike, linije za pranje plastike, usitnjivače, drobilice, sustave za granulaciju i ekstrudere za folije.

Kupci su naši cijenjeni poslodavci i ovdje ćemo u potpunosti poštovati vaše zahtjeve.

Naš pristup

NAŠA JE MISIJA BITI NAJBOLJI U INDUSTRIJI STROJEVA ZA RECIKLAŽU PLASTIKE!

POTPUNA USLUGA

Predani tim

Najbolji inženjeri

Podrška 24/7

Vizija tvrtke

Unapređenje budućnosti recikliranja plastike

Pružamo cijeli niz usluga, uključujući preliminarni dizajn, proizvodnju, postprodajnu uslugu itd.

UPOZNAJTE NAŠ TIM

RAZMJENA SVJEŽIH RAZMIŠLJANJA I

PRIHVATITE NOVE TEHNOLOGIJE

Ovim pismom Vas obavještavamo da je naš dobavljač bio vrlo dobar dobavljač. U našim brojnim poslovima s njima, utvrdili smo da su pouzdani i vrijedni povjerenja te Vam ih toplo preporučujemo kao dobavljača.

GOSPODIN DAMIAN FLEGEL

Izvršni direktorPotvrđujem da naša tvrtka u Australiji surađuje s tvrtkom Rumtoo već više od pet godina i s velikim zadovoljstvom ih preporučujemo za vaše potrebe. Vrlo smo impresionirani njihovom brzom uslugom i kvalitetnom opremom.

Maria Flynn

DR. ADRIAN SANCHEZ ROAOvim poslovnim referentnim pismom potvrđujemo da smo kupili opremu od tvrtke Rumtoo i da smatramo da je s njima vrlo lako surađivati, da su profesionalni i pouzdani. Svakako bismo ponovno surađivali s njima pri budućim kupnjama opreme i toplo ih preporučujemo drugima.

Gina Kennedy

MARK R. ALT, PE Direktor inženjeringaNAŠI PROIZVODI

UVIJEK BUDI U TOKU S

NAŠI NOVI BLOG I OBJAVE O PROIZVODIMA

Horizontal PVC Pipe Crusher: Designed for Maximum Efficiency

Our Heavy-Duty Horizontal Crusher is designed to handle high-volume PVC pipe scrap, converting your waste management challenges into a streamlined, efficient, and profitable operation.

Request a Quotation

The Advantage of Advanced Engineering

Discover why our horizontal crusher is the preferred choice for industrial-scale pipe and profile recycling.

Increased Efficiency

Significantly reduce the volume of PVC scrap, optimizing storage and streamlining your entire downstream process.

Enhanced Safety

The horizontal design allows for safe, ground-level feeding of long pipes, minimizing the risks associated with manual handling.

Significant Cost Savings

Lower transportation and storage costs by converting bulky pipes into dense, manageable material.

From Waste Pipe to Valuable Resource

Our crusher converts bulky PVC pipes into reusable material in three simple, automated steps.

Step 1: Material Feeding

Long sections of PVC pipe are safely and easily loaded into the wide, horizontal infeed hopper. The design prevents fly-back and ensures a steady flow into the crushing chamber.

Step 2: High-Torque Crushing

A powerful motor drives hardened steel blades at low speed and high torque, efficiently shattering and breaking down even the thickest-walled PVC pipes into smaller, uniform pieces.

Step 3: Sizing and Discharge

The crushed material passes through a heavy-duty screen, determining the final output size. The uniform chips are then discharged via a conveyor belt, ready for granulation or direct reprocessing.

Designed for Performance and Reliability

Explorar os componentes de última geração que definem o desempenho e a confiabilidade superior do nosso triturador.

- Robust Construction

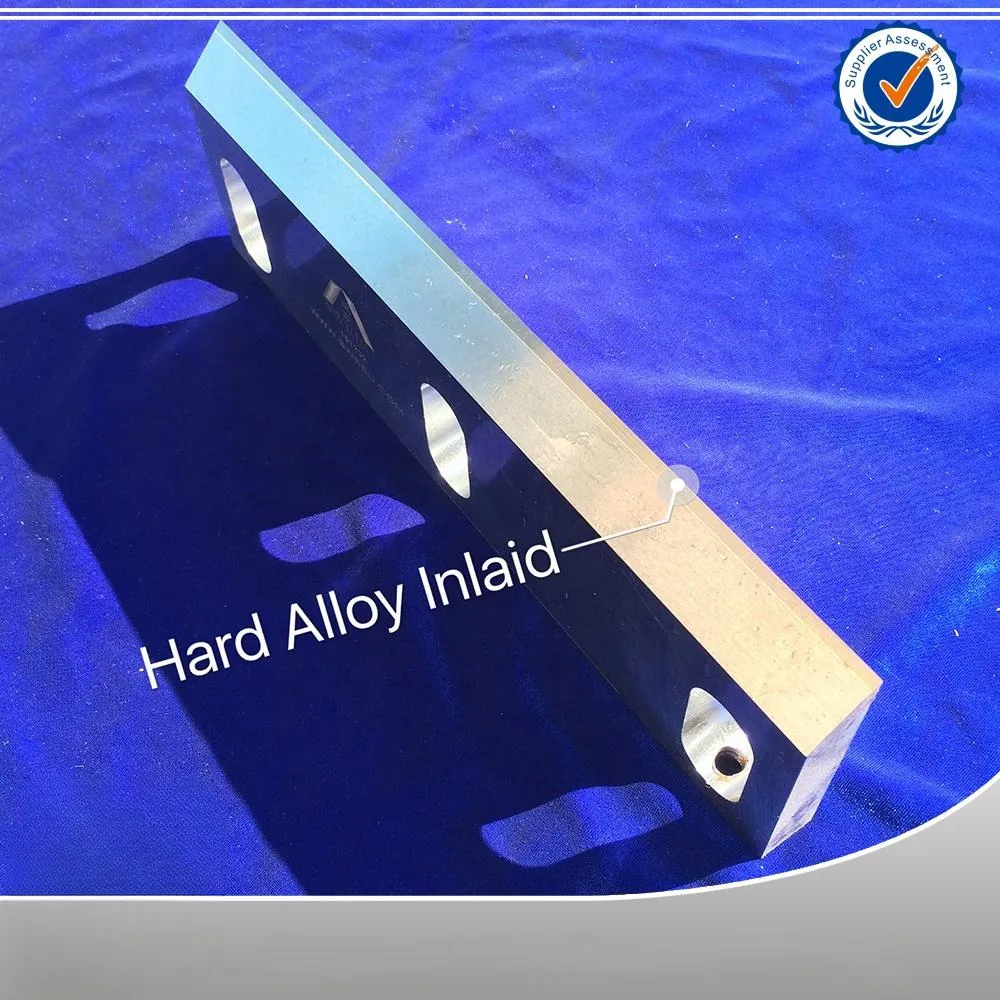

Crafted from high-grade steel to withstand the rigors of continuous operation in demanding recycling environments, ensuring exceptional durability and resistance to wear. - Hardened Cutting Blades

Equipped with a powerful motor and specially hardened cutting blades, our crusher delivers the immense force required to break down the toughest PVC pipe effortlessly. - Optimized Horizontal Design

The horizontal configuration simplifies the feeding of long pipe sections and optimizes material flow for continuous, uninterrupted operation. - Adjustable Output Sizing

Customize the output size of crushed PVC material with interchangeable screens to meet the specific requirements of your downstream processing equipment. - Low Noise Operation

Engineered with noise-dampening features to minimize acoustic pollution, creating a safer and more comfortable working environment for your staff. - Easy Maintenance

Designed for straightforward maintenance and cleaning, with accessible components to ensure maximum uptime, productivity, and a long service life.

Tehničke specifikacije

Detailed data for technical personnel and purchasing decision-makers.

| Model | Snaga (kW) | Brzina (o/min) | Promjer vijka (mm) | Hopper Volume (m³) | Izlaz (kg/h) |

|---|---|---|---|---|---|

| 560/630 | 22/37 | 2/4 | 500/550 | 0.3/0.5 | 250/350 |

| 730/830 | 55/75 | 4/4 | 600/800 | 0.5/1 | 450/700 |

| 1000/1300 | 90/110 | 4/6 | 900/1200 | 1/2 | 850/1200 |

See Our Granulator in Action

Watch how our horizontal granulator effortlessly handles long and bulky PVC pipes.

Request a Customised Solution and Quotation

Our team is ready to help you select the perfect model and configuration for your specific needs. Contact us today to achieve optimal efficiency and profitability.

Jamstvo: All machines and parts are guaranteed to be free from defects for a period of one year.

Često postavljana pitanja

What types and sizes of PVC pipe can this crusher handle?

Our horizontal crusher is designed for versatility. It can handle a wide range of PVC pipes, including solid wall, corrugated, and foam core pipes, with diameters and wall thicknesses varying by model. Please provide your specific pipe details for a precise recommendation.

How is the final output size of the material controlled?

The output size is determined by a perforated screen located beneath the crushing chamber. We offer a variety of screen sizes to produce different chip dimensions, allowing you to customize the output to perfectly match the input requirements of your granulators or other downstream equipment.

What is the maintenance schedule like for this machine?

The machine is designed for easy maintenance. Routine checks include blade inspection for wear and tear, lubrication of bearings, and ensuring the drive belt is tensioned correctly. Blades are rotatable and easily replaceable to minimize downtime. A full maintenance schedule is provided in the operational manual.

Do you provide installation and training?

Yes, we offer comprehensive support. This includes optional on-site installation and commissioning by our expert technicians. We also provide full training for your operators to ensure they can run and maintain the crusher safely and efficiently for maximum productivity.