In today's increasingly environmentally conscious world, businesses are seeking innovative solutions to reduce their ecological footprint while simultaneously improving their bottom line. Investing in a Recyclingmaschine für Plastikflaschen, specifically for PET bottles, is a powerful strategy that delivers on both fronts. This comprehensive guide will delve into the compelling reasons why a PET bottle recycling machine is a smart investment and provide a detailed, step-by-step roadmap for selecting the ideal one for your operational needs.

Essential Reasons to Invest in a PET Bottle Recycling Machine

Beyond mere compliance, embracing PET bottle recycling offers a multitude of tangible and intangible benefits that can significantly impact your business's success and reputation.

1. Champion Environmental Stewardship: Reduce Your Carbon Footprint

The most immediate and impactful benefit of recycling PET bottles is its profound positive environmental impact. By processing discarded PET, your business actively contributes to:

- Resource Conservation: Less virgin PET production means fewer fossil fuels consumed and reduced reliance on non-renewable resources.

- Reduced Landfill Waste: Diverting plastic bottles from landfills mitigates the growing problem of plastic pollution and extends landfill lifespans.

- Lower Greenhouse Gas Emissions: Recycling PET uses significantly less energy than producing new plastic from raw materials, leading to a substantial reduction in greenhouse gas emissions.

By visibly committing to these sustainable practices, your company not only aligns with global sustainability goals but also demonstrates a deep commitment to environmental responsibility, resonating with eco-conscious consumers and stakeholders.

2. Unlock Significant Cost Savings: Optimize Your Operations

Investing in a PET bottle recycling machine can lead to substantial and ongoing cost savings, directly impacting your operational efficiency and profitability.

- Reduced Raw Material Costs: For businesses that utilize PET in their own products, recycling allows for the reuse of plastic, minimizing or even eliminating the need to purchase new virgin materials.

- Lower Waste Management Expenses: By processing your own PET waste, you significantly decrease the volume of waste sent to landfills, leading to substantial savings on waste collection and disposal fees.

These combined savings can quickly offset the initial investment in the recycling machine, providing a clear financial incentive for adoption.

3. Cultivate New Revenue Streams: Embrace the Circular Economy

A PET bottle recycling machine isn't just an expense; it's an asset that can generate new income for your business.

- Selling Recycled PET: Processed PET flakes or pellets are a valuable commodity in the recycling market. You can sell these materials to other manufacturers who use recycled content in their products, creating a new and consistent revenue stream.

- Internal Product Manufacturing: If your business produces goods using PET, the recycled material can be re-incorporated into your own manufacturing process, leading to a more circular and sustainable production model while reducing external sourcing costs.

This ability to transform waste into a valuable resource is a cornerstone of the circular economy, offering a robust return on investment.

4. Ensure Regulatory Compliance: Stay Ahead of the Curve

The global regulatory landscape for waste management and recycling is constantly evolving and becoming more stringent. Proactively investing in an in-house Recyclingmaschine für Plastikflaschen ensures your business:

- Meets Local and International Regulations: Avoid potential fines and legal repercussions by adhering to increasingly strict waste disposal and recycling mandates.

- Enhances Corporate Reputation: Demonstrating a commitment to responsible waste management showcases your company as a responsible corporate citizen, a factor increasingly valued by consumers, investors, and partners.

Staying ahead of regulatory requirements not only mitigates risks but also positions your business as a leader in sustainable practices.

5. Boost Brand Image and Foster Customer Loyalty: Connect with Conscious Consumers

In today's market, consumers are increasingly making purchasing decisions based on a company's ethical and environmental practices.

- Improved Brand Perception: Visibly committing to recycling efforts through an in-house PET bottle recycling machine enhances your brand image, portraying your company as environmentally responsible and forward-thinking.

- Attract Eco-Conscious Customers: Sustainability is a powerful differentiator. Your commitment to recycling can attract a growing segment of consumers who prioritize eco-friendly businesses.

- Foster Customer Loyalty: Consumers often feel a stronger connection to brands that align with their values. By demonstrating environmental responsibility, you can build deeper trust and loyalty with your customer base.

These intangible benefits translate into increased market share and long-term business success.

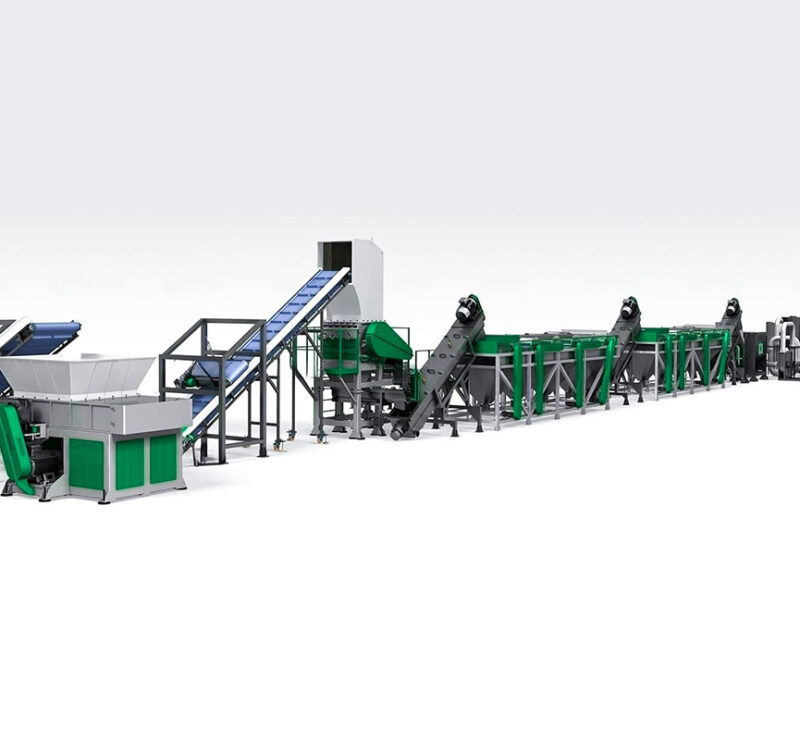

Schritt-für-Schritt-Anleitung zur Auswahl der richtigen PET-Flaschen-Recyclingmaschine

Selecting the optimal PET bottle recycling machine is crucial for maximizing your investment and ensuring efficient operations. This guide will walk you through the key considerations.

Understanding Your Business Needs: Laying the Foundation

Before diving into machine specifications, a thorough assessment of your operational requirements is essential.

- Assess Your Volume Requirements: Accurately determine the quantity of PET bottles your business handles on a daily, weekly, and monthly basis. This critical data will directly inform the required processing capacity of your machine.

- Evaluate Space Availability: Carefully consider the physical space available for the machine installation. Remember to account for not only the machine's footprint but also adequate room for material handling, storage of incoming bottles, and processed recycled material.

- Define Your Budget Considerations: Establish a clear budget for this investment. Beyond the initial purchase price, factor in installation costs, ongoing maintenance expenses, and operational costs such as electricity and labor. A comprehensive budget will prevent unexpected financial burdens.

Key Features to Look For: What Makes a Machine Stand Out?

Once you understand your needs, focus on the technical specifications that will ensure optimal performance.

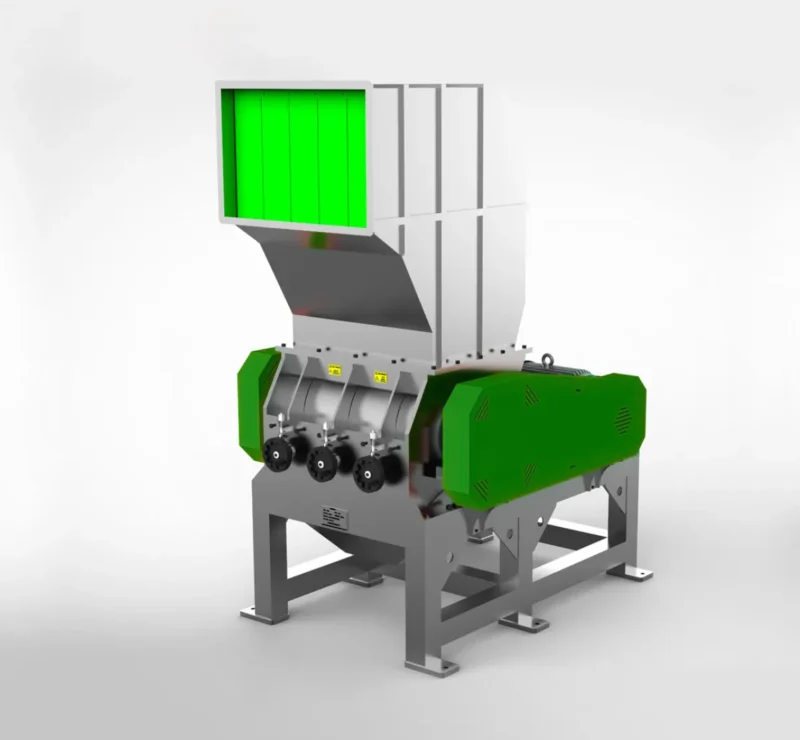

- Processing Speed (Throughput): Choose a machine whose processing speed aligns with your volume requirements. High-volume operations necessitate a faster machine to maintain efficiency and avoid bottlenecks.

- Energieeffizienz: Prioritize machines designed for energy efficiency. This will not only minimize your operational costs over time but also further reduce your environmental impact, aligning with your sustainability goals.

- Ease of Operation and Maintenance: Opt for a machine that is user-friendly and requires straightforward maintenance procedures. This ensures smooth daily operations, reduces the need for specialized technical skills, and minimizes costly downtime.

- Quality of Output: Critically evaluate the quality of the recycled PET material the machine produces. If you plan to sell the recycled material or use it in your own products, it must meet industry standards for purity, size, and other specifications. A high-quality output maximizes the value of your recycled material.

Calculating Potential Return on Investment (ROI): Justifying Your Investment

A strong ROI is key to securing internal buy-in and demonstrating the financial viability of your investment.

- Compare Initial Costs vs. Long-Term Savings: Conduct a detailed financial analysis, comparing the initial capital expenditure with the projected long-term savings on raw material purchases and waste management fees. Often, a higher upfront cost for a more efficient and durable machine can be justified by significant savings and increased revenue over its lifespan.

- Estimate Revenue from Recycled PET: Research current market rates for recycled PET flakes or pellets. Based on your projected output volume, estimate the potential revenue you can generate from selling this valuable commodity.

- Factor in Intangible Benefits: While harder to quantify directly, consider the substantial intangible benefits. Improved brand image, increased customer loyalty, enhanced regulatory compliance, and a stronger reputation as a sustainable company can indirectly contribute to significant financial gains through increased sales and avoided penalties.

Finalizing Your Decision: Making an Informed Choice

The final steps involve due diligence and securing the best possible partnership.

- Research Manufacturers and Suppliers: Thoroughly investigate various manufacturers and suppliers of plastic bottle recycling machines. Look for companies with a proven track record, positive customer reviews, and a reputation for reliable products and excellent after-sales support.

- Request Detailed Quotes and Proposals: Obtain comprehensive quotes and proposals from multiple reputable vendors. Compare them not only on price but also on included features, warranty, installation services, and ongoing support.

- Conduct Site Visits and Demonstrations (If Possible): Whenever feasible, arrange to visit facilities where the machines you are considering are currently in operation. This provides invaluable firsthand insight into their performance, reliability, and ease of use in a real-world setting.

- Prioritize After-Sales Support and Training: Confirm that the supplier offers comprehensive after-sales support, including technical assistance, spare parts availability, and training programs for your staff. This is paramount for maintaining efficient operations, troubleshooting any issues promptly, and maximizing the lifespan of your machine.

Abschluss

Investieren in eine Recyclingmaschine für Plastikflaschen for PET is more than just an operational upgrade; it's a strategic imperative for businesses aiming to enhance both their sustainability credentials and their financial profitability. By meticulously assessing your specific needs, diligently evaluating key machine features, and thoroughly calculating your potential return on investment, you can confidently select the ideal machine. This pivotal decision will not only align with your business goals but also secure a robust and rewarding return on investment, propelling your company towards a more sustainable and prosperous future.