PET Bottle Washing & Recycling Machine

Our state-of-the-art PET bottle washing and recycling line delivers clean, high-value flakes ready for the market. Engineered for uptime and profitability.

Why Our PET Washing Line Delivers Results

Maximizing throughput while ensuring premium quality output.

Maximize Your Throughput

Our powerful crushing mechanism acts as the engine of your line, processing materials faster to boost overall plant output.

Achieve Premium Purity

Advanced sorting technology removes contaminants with precision, delivering premium-grade recycled flakes that command higher prices.

Simplify Your Operations

An intuitive, user-friendly interface empowers any operator to confidently manage the line, minimizing training time and errors.

Optimize Your Floor Space

Get maximum processing power in a minimal footprint. Our compact design allows for flexible layouts.

Built for Non-Stop Performance

Engineered with durable materials, our machine is built for the rigors of 24/7 operation, ensuring maximum uptime.

Lower Operational Costs

Smart, energy-efficient technology reduces power consumption per ton, directly cutting down operational expenses.

Proven Results: See the Difference

From contaminated waste to premium market-ready flakes.

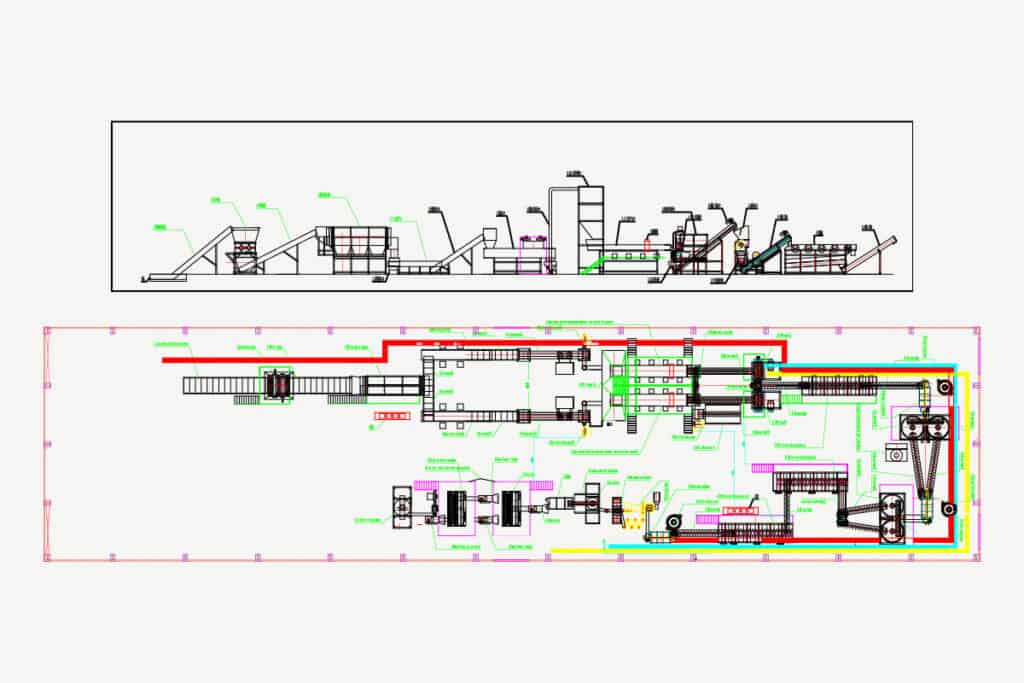

Explore The Technology Inside

A deep dive into our multi-stage washing and recycling process.

01. Debaler Machine

The first step in our plastic bottle washing line is to break the compacted bales of PET bottles into a free-flowing stream. Once the bales are “busted”, the bottles can move freely onto the next machine.

02. Trommel

An optional piece of equipment, the trommel is a slowly rotating tunnel lined with small holes that are slightly smaller than the PET bottles. Small pieces of contamination such as glass, metals, rocks/dirt, and paper fall through the holes while the PET bottles move forward.

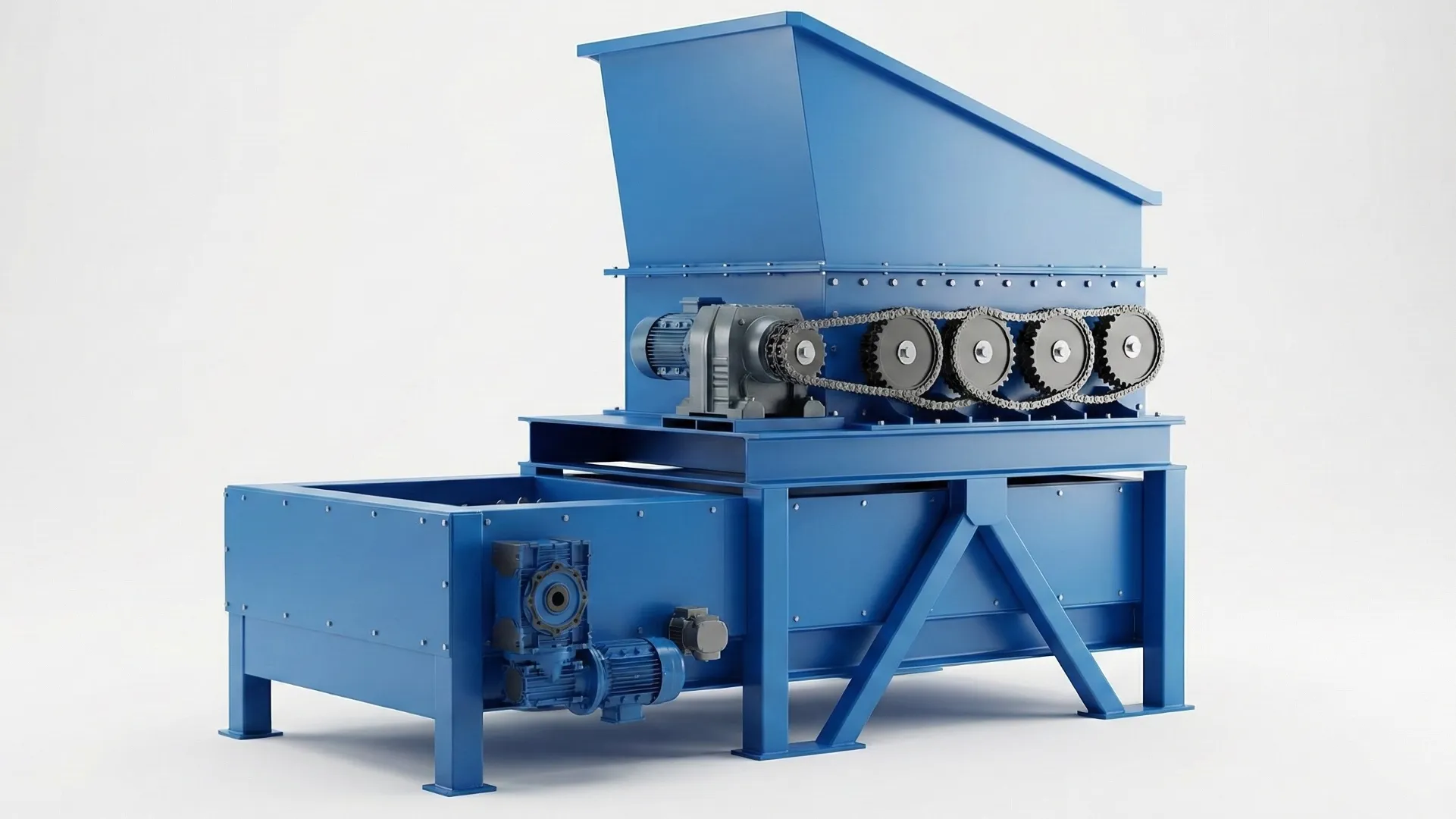

03. Wet Plastic Crusher

Sometimes referred to as a plastic granulator, this machine cuts the PET bottles into small flakes between 10-15mm. With water constantly spraying into the cutting chamber, this wet granulation process pre-treats and partially cleans the material.

04. Air Classifier

Air classification separates lighter materials from heavier ones. The main purpose here is to remove contaminations such as paper, cardboard, and plastic labels away from the heavier PET flakes using an air stream.

05. Sink/Float Separation Tank

Using water as a medium, materials are separated by density. PET plastic sinks, while plastic film (labels) and PP/PE (caps) float. A screw conveyor at the bottom moves the clean PET to the next stage.

06. Hot Washer System

Hot washed PET flakes are higher value because this process dissolves glues (from labels) and leftover residue. Use water or add washing agents for superior cleaning results.

07. Friction Washer

An efficient cold water washing unit, the high-speed friction washer uses mechanical friction (over 1000 RPM) to scrub away any remaining hard-to-remove dirt and debris from the PET flakes.

08. Dewatering Machine

The first step in drying. Our centrifugal dewatering machine uses high-speed rotation to remove a large portion of water from the surface of the PET flakes before thermal drying.

09. Thermal Dryer

Flakes travel down stainless steel tubes mixed with hot air, dehydrating any remaining moisture. A cyclone separator then mixes the flakes with cool air to prepare them for storage.

10. Product Silo

A final storage tank for the clean, dry PET flakes, ready for bagging or direct transport to a pelletizing line.

11. Pelletizer (Optional)

For customers requiring granules, we offer single-screw and twin-screw extruder pelletizers to convert the clean flakes into uniform high-quality plastic pellets.

Technical Specifications

Customizable capacities to meet your recycling plant's demands.

Standard Line Parameters

We offer solutions from 500kg/h to 3000kg/h.

| Parameter Model | PET-1000 | PET-3000 |

|---|---|---|

| Input Capacity | 1000 - 1500 kg/h | 3000 - 3500 kg/h |

| Final Product | Clean PET Flakes | Clean PET Flakes |

| Flake Size | 10 - 15 mm | 10 - 15 mm |

| Moisture Content | < 1% | < 1% |

| PVC Content | < 100 ppm | < 100 ppm |

| Total Power | ~350 kW | ~800 kW |

See The Machine In Action

Watch our PET bottle recycling machine verify its performance.

Client Success Stories

Trusted by recyclers to deliver high-quality PET flakes.

"Rumtoo's PET washing line transformed our business. The hot washer system is exceptional at removing label glues, giving us a very pure product."

"The energy efficiency of this line is impressive. We've seen a noticeable drop in power costs per ton compared to our old equipment."

"Robust construction and easy to maintain. The dewatering performance prepares the flakes perfectly for our pelletizers."

Complete Your Recycling Plant

Explore our other solutions for a fully integrated recycling facility.

Frequently Asked Questions

What is a PET Bottle Recycling Machine?

How does the machine work?

What types of PET bottles can be processed?

What are the benefits of using this machine?

How much does a PET Bottle Recycling Machine cost?

Where can I buy a PET Bottle Recycling Machine?

Request a Free Layout Design

Ready to upgrade your plant? Contact us for a solution tailored to your facility.