Introduction of Double Shaft Shredder

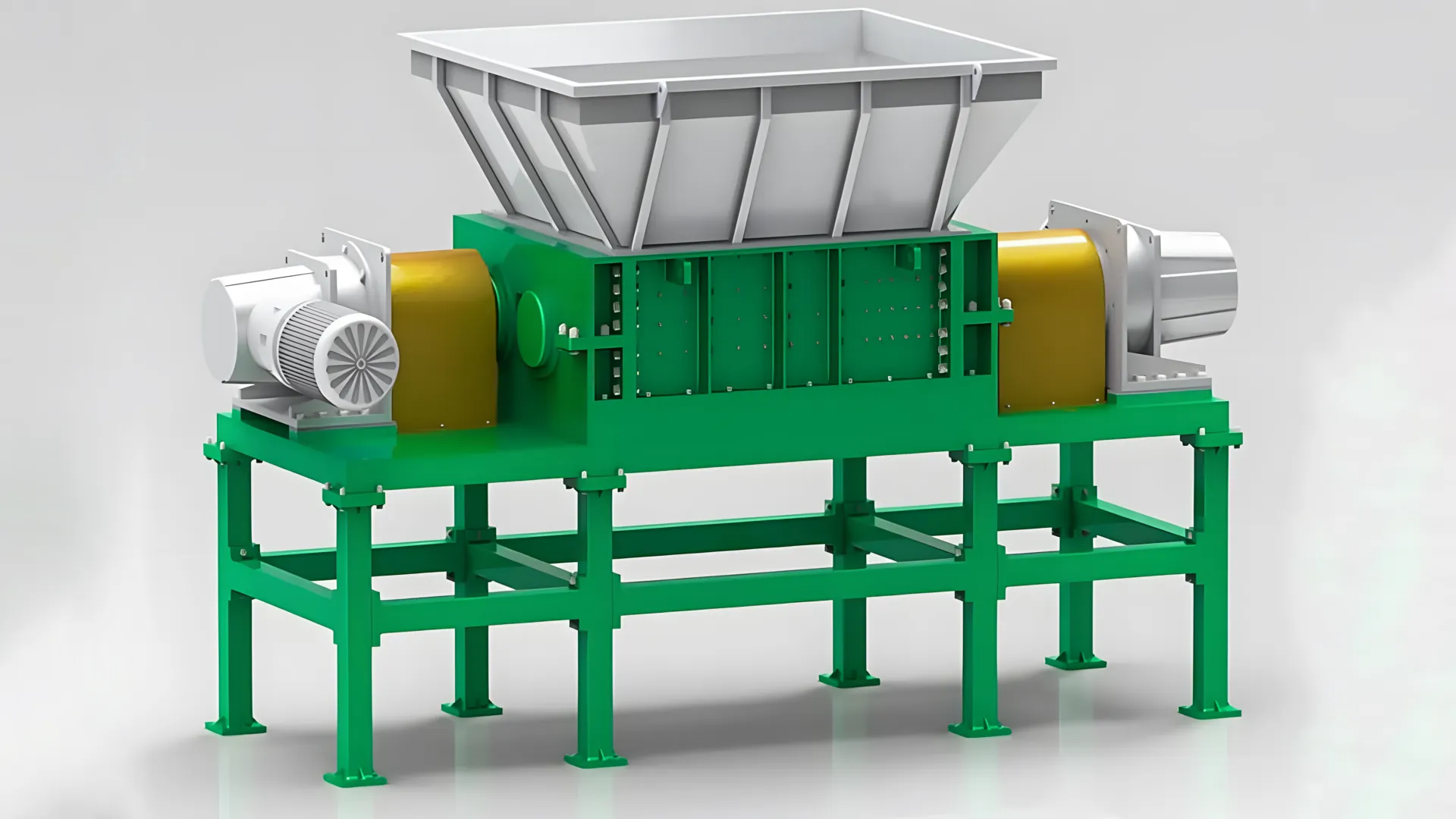

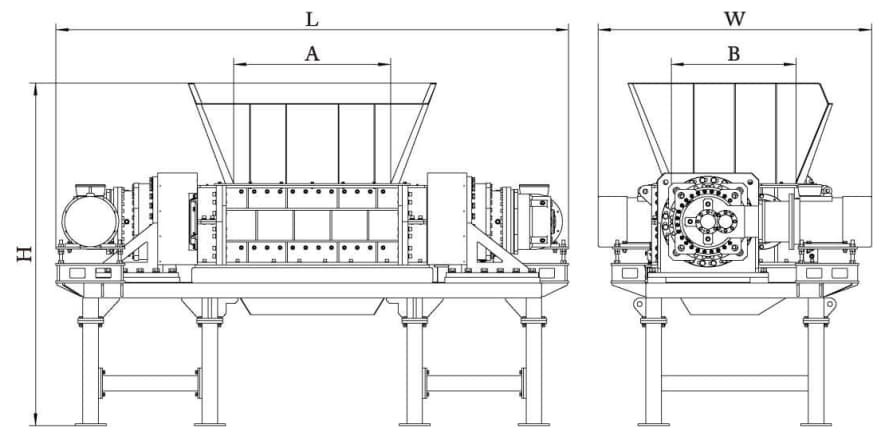

Our double-shaft plastic shredder machines are a critical part of the plastic recycling process. They are designed to handle large volumes of bulky plastic materials, such as bales of plastic film and rigid plastics. These heavy-duty machines use low-speed, high-torque technology to pre-cut the materials, making it easier to process them further down the line. Additionally, our shredders feature a wide intake chute opening, which allows for a more efficient and effective shredding process. The materials are shredded into small pieces, typically between 1-5 inches, making them easier to handle and transport. By investing in our double-shaft plastic shredder machines, you can streamline your plastic recycling process, save time, and reduce waste.

Double shaft shredder is a commonly used crushing equipment, widely used in waste recycling, biomass energy utilization, recycling, wood processing, electronic waste processing, plastic recycling, and other industries. Specific applications include the following aspects:

- Plastic Recycling Field: Double shaft shredder can be used to process waste plastic products, such as plastic bottles, plastic pipes, plastic films, plastic sheets, etc., and crush them into small particles for subsequent classification, cleaning, recycling, and other treatments.

- Wood Processing Field: Double shaft shredder can also be used to process wood waste, such as wood boards, wood strips, sawdust, etc., and crush them into wood chips or wood powder for the production of biomass fuel, pressing into wood pellets, etc.

- Electronic Waste Processing Field: Double shaft shredder can handle electronic waste, such as wires, cables, discarded appliances, mobile phones, etc., and crush them into small particles for classification and extraction of valuable metals and other materials.

- Recycling Resource Utilization Field: Double shaft shredder can be used to process various waste materials, such as waste tires, scrap steel, waste fabrics, etc., and crush them into small particles for subsequent classification, cleaning, and extraction of valuable materials.

Generally speaking, double shaft shredder has a wide range of application prospects in waste treatment and recycling resource utilization, and has made important contributions to promoting circular economy, energy conservation and emission reduction, environmental protection and governance, etc.

Jednoosovinski u odnosu na dvoosovinski drobilice plastike

Značajka

Single-shaft shredders are better suited for handling solid, thick pieces such as plastic purging, runners, pallets, and even wood, branches, and bones. Double-shaft shredders use shear blades to cut the plastic material and are better suited for handling bulk volumes of hollow, lightweight plastics such as PE films, PP tubes, HDPE drums, and even rubber tires, automotive parts, and electronic waste.

Uvod

Plastic waste has become a major environmental issue in recent years. As a result, many companies and organizations are looking for ways to reduce their plastic waste and improve their sustainability efforts. One solution that has gained popularity in the industry is the double-shaft plastic shredder. In this blog post, we will explore the benefits and applications of this versatile machine.

Efficient and Versatile

The double-shaft plastic shredder is a powerful machine that can shred large quantities of plastic waste in a short amount of time. It is equipped with two shafts that rotate in opposite directions, which ensures that the plastic waste is shredded evenly and efficiently. This machine can handle a wide range of plastic materials, including PVC, PET, HDPE, and more. Additionally, the double-shaft plastic shredder can be used for various applications, such as recycling, waste reduction, and even product destruction.

Safe and Reliable

Safety is a top priority when it comes to operating any machinery, and the double-shaft plastic shredder is no exception. These machines are equipped with safety features such as emergency stop buttons, safety guards, and overload protection. Additionally, the double-shaft plastic shredder is designed to be easy to maintain, which ensures that it operates reliably and efficiently over time.

Cost-Effective and Environmentally Friendly

Investing in a double-shaft plastic shredder can be a cost-effective solution for companies and organizations that generate a lot of plastic waste. By shredding the plastic waste on-site, companies can reduce their transportation costs and landfill fees. Additionally, shredding plastic waste is an environmentally friendly solution, as it reduces the amount of plastic that ends up in landfills or pollutes our oceans.

Zaključak

The double-shaft plastic shredder is a versatile and efficient solution for companies and organizations that want to reduce their plastic waste and improve their sustainability efforts. With its ability to handle a wide range of plastic materials and applications, it is a valuable addition to any waste management system. Not only is it cost-effective and environmentally friendly, but it also ensures the safety and reliability of the shredding process. Investing in a double-shaft plastic shredder is a smart choice for any company that wants to make a positive impact on the environment while also saving money in the long run.

Advantages

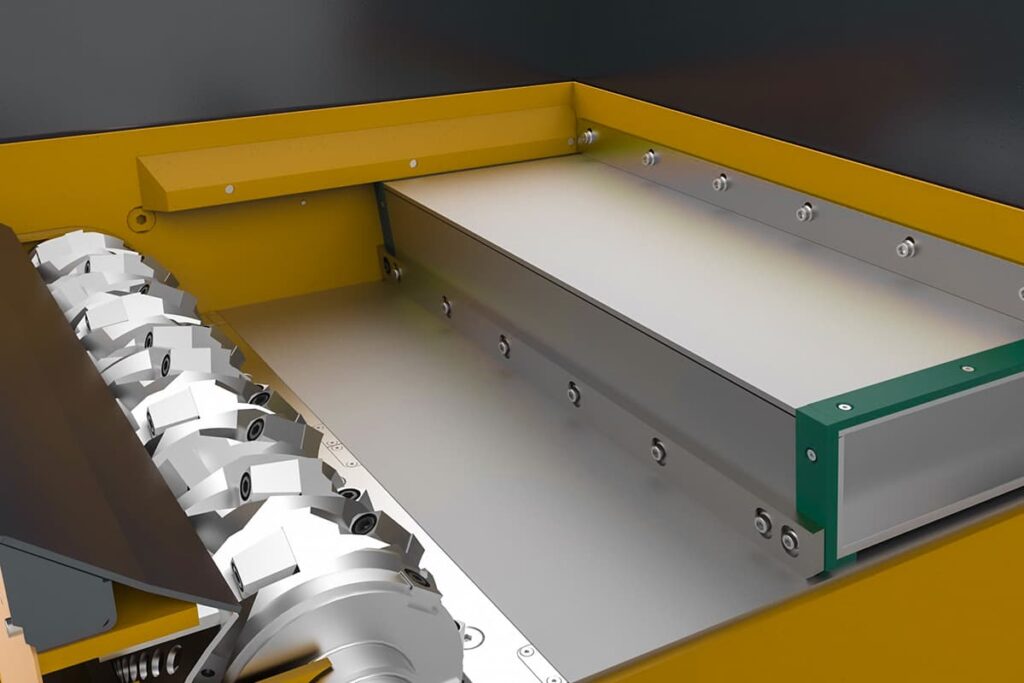

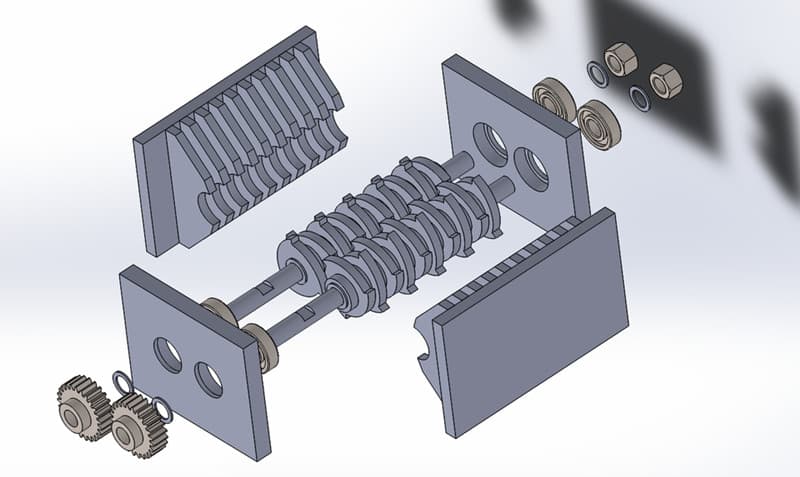

- The knife adopts high alloy steel 42CrMo, which has high strength and toughness.

- The blade of D-rotor and DM rotor adopts D2 steel, and the knife adopts 42CrMo steel.

- The main electrical components are trusted brands such as Siemens and Schneider.

- The auto-reverse system re-orients the rotor direction when the motor is overloaded or the material is jammed.

- The pusher ram is optional for hollow and gigantic materials.

Jamstvo

Svi strojevi za recikliranje dolaze s jednogodišnjim ograničenim jamstvom.

UPITI

Za najnovije cijene i rokove isporuke, pošaljite nam poruku putem obrasca ispod.