Linija za pranje PET boca

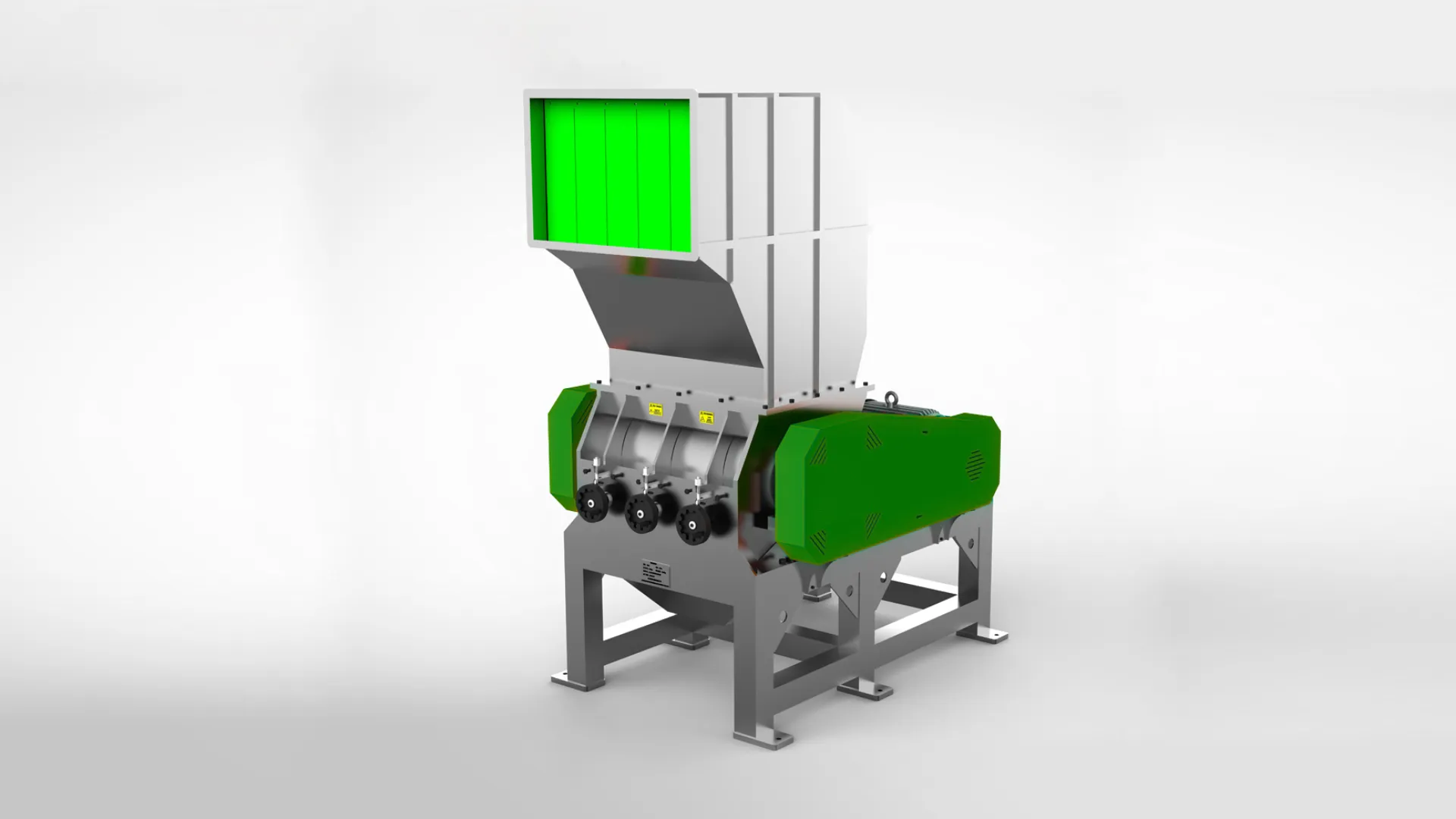

Standard Plastic Granulator is a type of machinery designed specifically for crushing and processing plastic waste. It can quickly and effectively crush various types of plastic products, such as bottles, pipes, containers, and woven bags, into small particles, providing convenience for subsequent processing.

The working principle of the Plastic Crusher is to use a rotating cutter wheel to quickly cut and crush plastic waste into small pieces, which enter the sieve hole with the rotation of the cutter wheel and further crush into small particles. The crushed small particles can be directly used for plastic product manufacturing, or further processed and recycled.

Plastic Granulator is widely used in plastic recycling, waste disposal, and granulation. By using this equipment, waste pollution to the environment can be minimized, waste disposal costs can be reduced, and convenience is provided for plastic recycling. In addition, Plastic Crusher is easy to operate, safe, and reliable, and can be adjusted and optimized according to different material characteristics and processing requirements.

In summary, Plastic Granulator is an efficient, reliable, and environmentally friendly machinery that can be widely used for recycling and utilization of plastic waste, providing effective technical means for sustainable development.

Naši standardni teški strojevi za granulaciju plastike, ponekad nazvani drobilice plastike, ključni su strojevi u industriji recikliranja plastike.

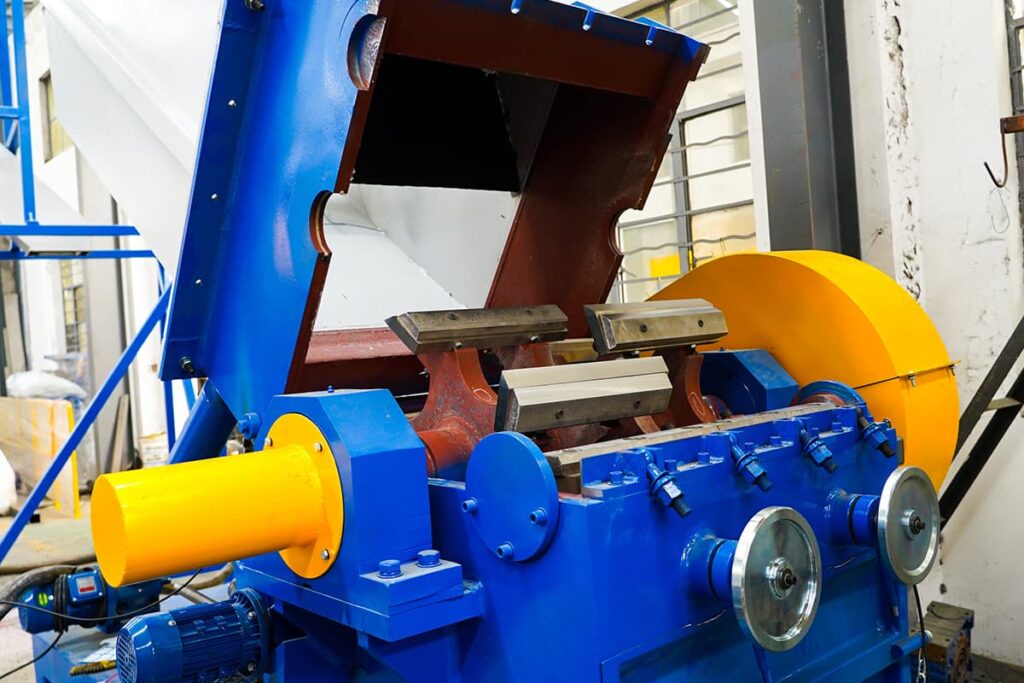

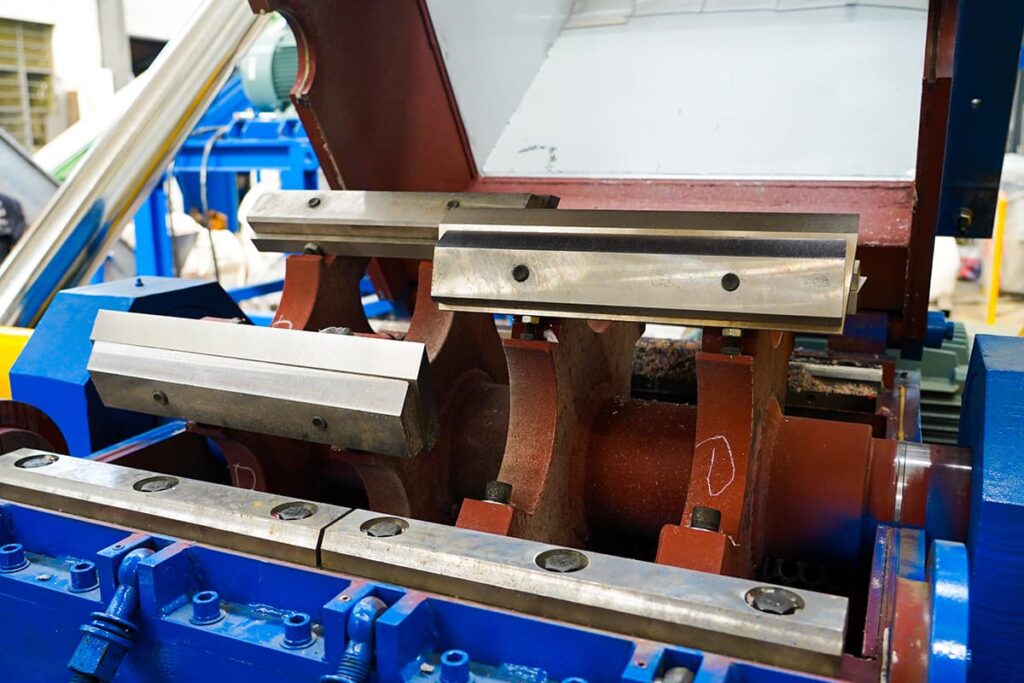

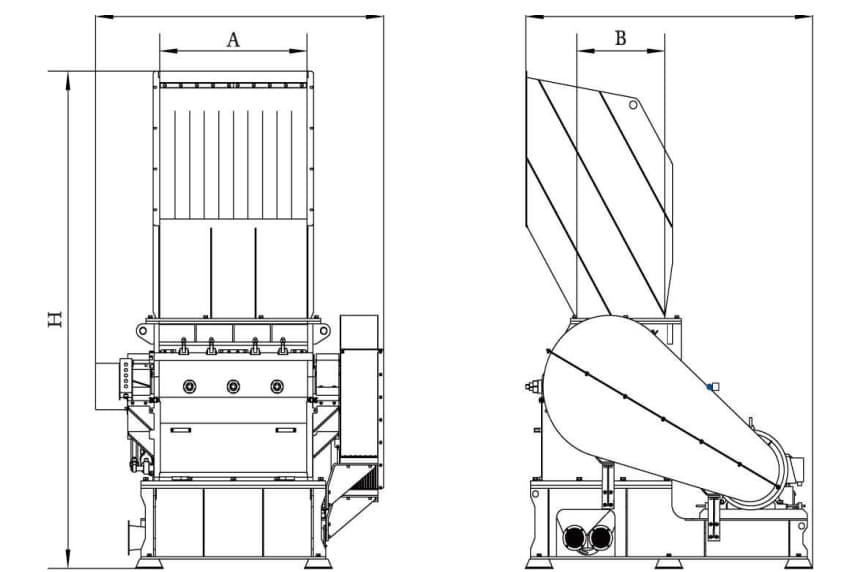

Our plastic granulator machine operates with an open rotor that is mounted with heavy-duty knives in either a double-scissor cut or v-shape array based on your needs. As the rotor spins at high speeds, its knives come into contact with stationary knives mounted within the cutting chamber. The material is continuously cut until it is small enough to pass through a screen filter. Our filter screens typically range from 10mm to 100mm, but can be customized according to your requirements. Our standard plastic granulator contains 12 rotor knives and 3 stationary knives. All knives use ultra-durable D2 (equivalent to SDK11) high-carbon, high-chromium steel, ensuring the longest usage times before requiring sharpening. The knives are easily adjustable with hydraulic-assisted access to the cutting chamber.

All recycling machines come with a 1-year limited warranty.

This general-purpose plastic granulator can be used for various applications of plastic recycling, including but not limited to grinding plastic bottles, films, and various small hard plastics.

Our plastic granulator is easy to operate, safe and reliable, and can be adjusted and optimized according to different material characteristics and processing requirements. In addition, using a plastic granulator can minimize environmental pollution, reduce waste disposal costs, and provide convenience for plastic recycling. It is an efficient, reliable, and environmentally friendly mechanical equipment, providing effective technical means for sustainable development.

Furthermore, for more convenience, we also provide wet plastic granulators, which have additional rubber seals and connected inlet hoses that allow continuous spraying of water during plastic cutting. This helps to clean plastic waste while keeping the blades cool during operation, thereby improving production efficiency and product quality.

Plastic granulators and shredder machines are both used in the recycling industry to process plastic waste, but they serve different purposes.

Plastic shredders are primarily used to reduce the size of bulky plastic products, such as large plastic containers, drums, and pipes, into smaller pieces that can be easily transported and processed. They use sharp blades to tear, shear, and slice the plastic waste into smaller pieces.

Plastic granulators, on the other hand, are used to process smaller plastic waste, such as plastic bottles, films, and small hard plastics, into small particles that can be directly used for plastic product manufacturing or further processed and recycled. They use rotating cutter wheels to cut and crush plastic waste into small pieces, which enter the sieve hole with the rotation of the cutter wheel and further crush into small particles.

Both plastic shredders and granulators can be adjusted and optimized according to different material characteristics and processing requirements. Choosing the right equipment depends on the type and size of plastic waste being processed, as well as the desired output size and quality.

Za najnovije cijene i rokove isporuke, pošaljite nam poruku putem obrasca ispod.

Plastic waste is one of the biggest environmental challenges facing our planet today. With millions of tons of plastic ending up in landfills, oceans, and natural habitats each year, it’s clear that we need to find better ways to manage this problem. One crucial step in the plastic recycling process is washing and cleaning the materials to remove contaminants and impurities. In this article, we’ll explore the state-of-the-art plastic recycling washing systems that are leading the way in creating a cleaner, more sustainable future.

Rigid Plastic Washing Recycling Line is a revolutionary technology that is transforming the way waste plastic is recycled. This technology is designed to help companies reduce their plastic waste footprint and promote environmental sustainability.

The market for recycling PE PP rigid materials is growing rapidly. These materials are used in a wide variety of plastic products that we use in our daily lives, including milk bottles, food packaging boxes, shampoo bottles, plastic chairs, tables, and pipes. At our recycling facility, we understand the importance of properly recycling these materials, which is why we have designed and customized our recycling machines to meet the unique needs of different types of PE PP rigid materials.

Our complete recycling solution includes a heavy-duty shredder with an overhead magnet, a granulator, a sink-float separation tank, a centrifugal dryer, a thermal dryer, a zigzag separator, and a dual-bag filling station. These machines work together to ensure that the waste materials are properly washed and recycled, resulting in high-quality plastic flakes that can be used in the manufacturing of plastic products once again.

By using our rigid plastic washing Recycling Line, you can contribute to a cleaner environment and promote sustainable manufacturing practices. We are committed to providing reliable and efficient recycling solutions that meet your needs and exceed your expectations. Contact us today to learn more about our PE PP rigid material recycling services.

Thanks to our innovative washing technology and high-quality performance, we are able to provide reliable and efficient recycling solutions for our customers. Our commitment to using the latest technology ensures that our recycling processes are environmentally friendly and sustainable, while also delivering high-quality results.

Using Rigid Plastic Washing Recycling Line has numerous benefits for both the environment and businesses. Some of the benefits include:

Rigid Plastic Washing Recycling Line is an innovative technology that is transforming the plastic waste recycling industry. It is a highly efficient and cost-effective process that provides numerous benefits to both the environment and businesses. By using this technology, companies can reduce their plastic waste footprint and promote environmental sustainability.

Linija za recikliranje krute plastike

PS:Equipment configuration and the process will be optimized according to raw materials.

All recycling machines come with a 1-year limited warranty.

Za najnovije cijene i rokove isporuke, pošaljite nam poruku putem obrasca ispod.