Rinsing and Sedimentation Separation: The Principle of Separating Light and Heavy Materials in Bottle Recycling

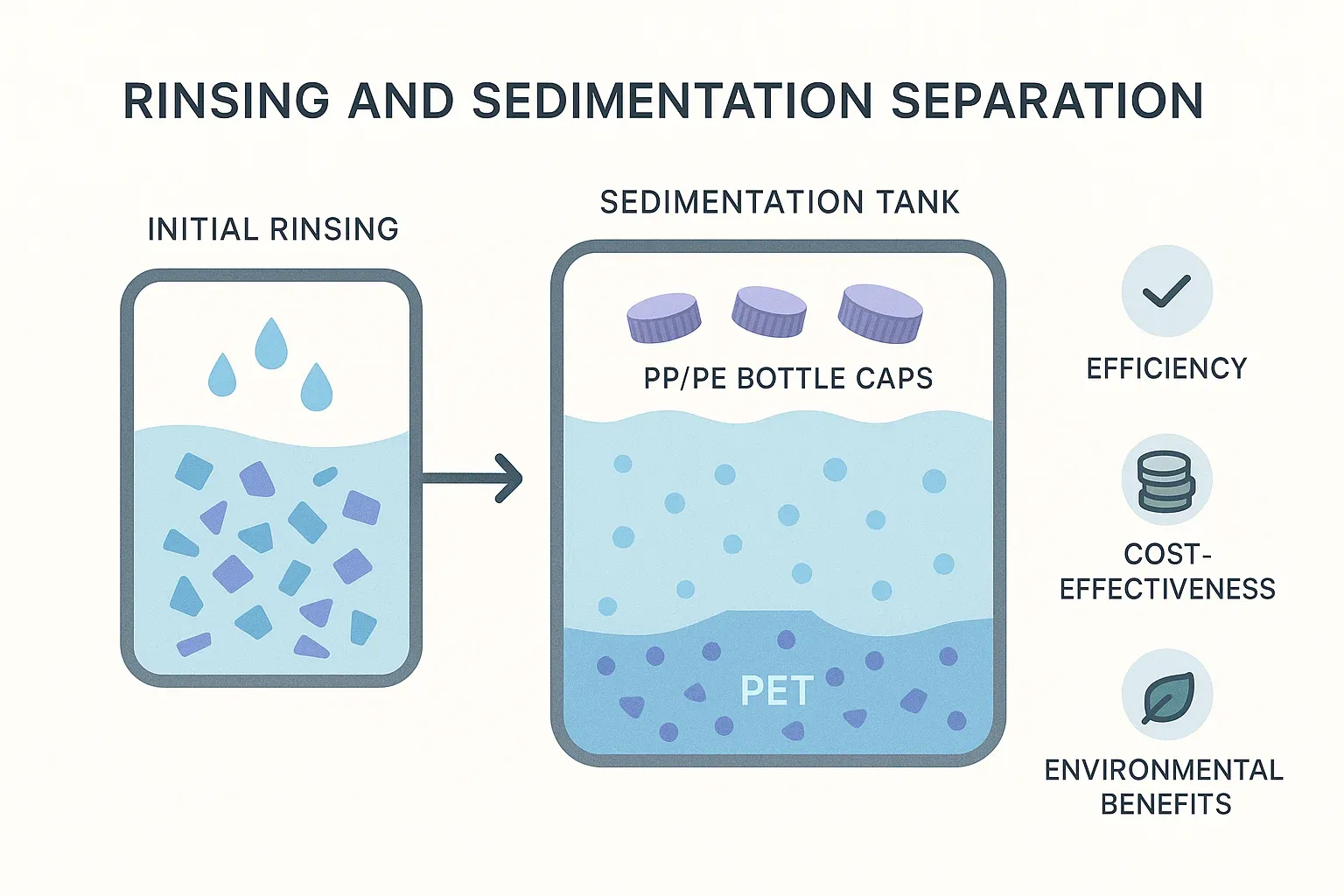

Recycling technology has advanced significantly, allowing industries to efficiently reclaim valuable resources from waste. One particularly effective method is the rinsing and sedimentation separation process, especially vital in bottle recycling, where separating lightweight plastics like bottle caps (PP/PE) from heavier materials (e.g., PET bottles) is crucial.

Understanding Rinsing and Sedimentation Separation

In recycling plants, rinsing and sedimentation separation leverage the differences in density between various plastics to efficiently segregate materials. Typically, PP (polypropylene) and PE (polyethylene)—materials commonly used for bottle caps—are lighter than PET (polyethylene terephthalate), the primary material used in bottles. This density differential is key to their effective separation.

How the Separation Process Works

1. Initial Rinsing

The recycling line starts by thoroughly rinsing shredded plastic bottles and caps, removing residues and contaminants. This step is essential as it prepares the materials for effective density-based separation.

2. Sedimentation Tank Operation

Following rinsing, the plastic fragments enter a sedimentation tank filled with water. Here, gravity and buoyancy act as the core principles facilitating separation:

- Heavier materials (PET) sink to the bottom.

- Lighter materials (PP/PE bottle caps) float to the surface.

This straightforward yet powerful mechanism allows easy separation and collection of different plastic fractions.

Advantages of the Rinsing and Sedimentation Method

- Učinkovitost: Achieves high purity in separated plastic streams.

- Cost-effectiveness: Reduces operational costs by simplifying downstream processing.

- Environmental benefits: Minimises contamination and enhances recycling rates, significantly reducing plastic waste.

Technical Considerations for Optimal Results

To maximise effectiveness, recycling professionals must consider:

- Water Quality: Maintaining clean and well-managed water improves separation accuracy.

- Material Size and Consistency: Uniformly shredded plastics improve the efficiency of the sedimentation process.

- System Maintenance: Regular maintenance and checks ensure consistent performance and reliability of machinery.

Enhancing Clarity with Diagrams and Performance Charts

Including clear diagrams or charts illustrating the sedimentation process can significantly enhance understanding. Visual aids showing equipment workflows, density-based material sorting, and comparative performance of separation technologies provide industrial buyers and engineers with a comprehensive overview.

Industry Applications and Success Cases

Industries adopting rinsing and sedimentation separation technology have seen significant benefits:

- Improved material recovery rates.

- Higher purity of recycled materials.

- Increased economic returns from recovered plastics.

Why Rumtoo?

Rumtoo’s machinery integrates advanced rinsing and sedimentation separation technologies, delivering reliable, high-performance solutions tailored specifically for the recycling industry. Our machines are designed to meet the rigorous demands of recycling facilities, ensuring both operational efficiency and environmental compliance.

With Rumtoo, recycling professionals gain a trusted partner, committed to supporting sustainable practices through innovative technology and unparalleled expertise in bottle recycling.

By clearly understanding and effectively utilising the principles of rinsing and sedimentation separation, recycling operations can achieve superior efficiency, economic benefits, and environmental sustainability in their processes.