Introduction to the Component Composition and Working Principle of a Single-Axis Shredder

Single-Shaft Shredder is a mechanical equipment primarily utilized for the crushing, processing, and recycling of waste materials. Its primary components encompass the following elements:

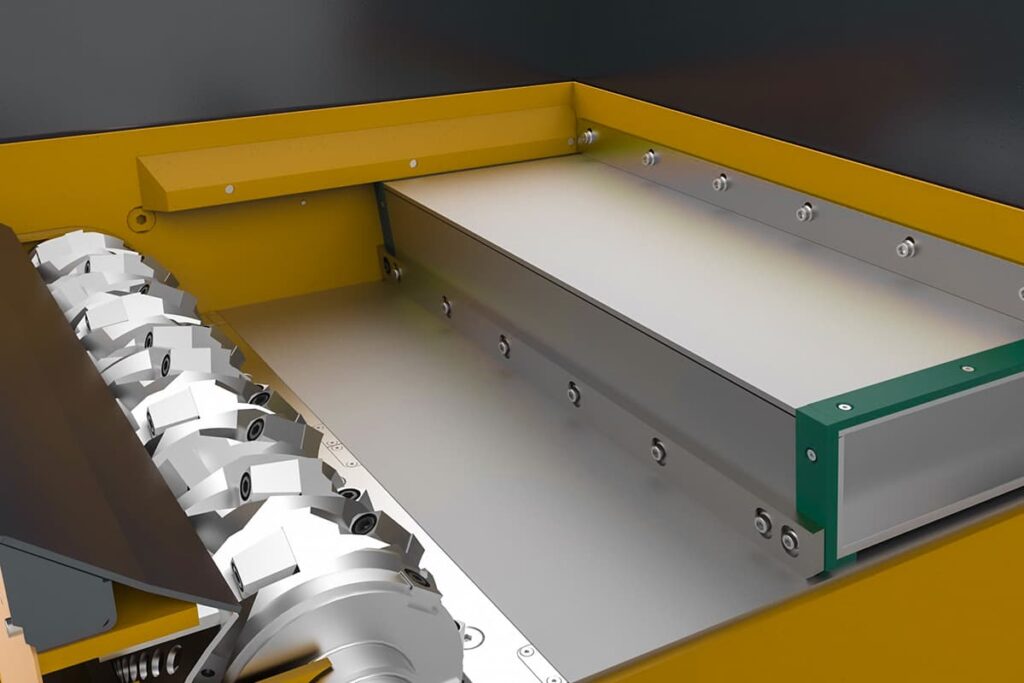

- Shaft: The shaft serves as the core component of the single-shaft shredder, propelling the blades to crush the materials. Typically crafted from high-strength steel, the shaft is engineered to endure high-load operating conditions.

- Blades: The blades are integral components mounted on the shaft, responsible for shearing, tearing, cutting, and grinding materials. They are commonly made from high-hardness, high-wear-resistant alloy steel to guarantee an effective crushing outcome and extended service life.

- Feed Hopper: The feed hopper is a crucial component of the single-shaft shredder, designed to introduce waste materials into the machine. The dimensions and shape of the feed hopper are generally tailored and optimized based on the material properties and processing demands.

- Discharge Outlet: The discharge outlet is an essential aspect of the single-shaft shredder, facilitating the ejection of shredded particles from the machine. The design of the discharge outlet is typically formulated in accordance with the material characteristics and processing requirements.

- Sistema de Propulsión: El sistema de propulsión es una parte esencial del desmenuzador de eje único, encargado de transmitir la energía del motor eléctrico al eje y las cuchillas. Este sistema generalmente incluye un motor, un reductor, un acoplamiento y otros componentes.

El principio de funcionamiento del desmenuzador de eje único es que los materiales de desecho entran en la máquina a través de la tolva de alimentación, son cortados en pequeñas piezas por las cuchillas y se empujan continuamente hacia adelante hasta que son desmenuzados en partículas pequeñas y expulsados por la salida de descarga. Durante todo el proceso de trituración, la rotación a alta velocidad de las cuchillas provoca diversas fuerzas como la fricción, el corte y la desgarradura de los materiales, lo que permite una trituración y procesamiento efectivos de los desechos.

Comparación entre trituradores de plástico de eje único y doble

Característica

| Modelo | DS-600 | DS-800 | DS-1000 | DS-1200 |

|---|---|---|---|---|

| Capacidad (kg/h) | 30 kW | 45kW | 2x37 kW | 2x45 kW |

| Potencia del motor hidráulico | 4 kW | 4 kW | 5.5 kW | 5.5 kW |

| Material de cuchilla | SKD11 | SKD11 | SKD11 | SKD11 |

| Main Motor Power | Φ400 | Φ400 | Φ450 | Φ500 |

| Rotary Diameter (mm) | 85 | 85 | 80 | 70 |

| Rotation Speed (rpm/min) | 400-600 | 600-800 | 800-1200 | 1500-2000 |

Single-shaft shredders are more suitable for processing solid, thick materials such as plastic purge, runners, pallets, as well as wood, branches, and bones. Double-shaft shredders utilize shear blades to cut plastic materials and are better suited for handling large volumes of hollow, lightweight plastics such as PE films, PP tubes, HDPE drums, and even rubber tires, automotive parts, and electronic waste.

Introduction

Single Shaft Shredder machines are utilized for the downsizing of various materials. They are engineered to handle a range of materials, including plastics, rubber, wood, paper, and other waste materials. These machines are employed across industries to process waste materials into a more manageable size.

High-Quality Output

The Single Shaft Shredder is engineered to deliver high-quality output. The machine features a rotor that is fitted with blades. The rotor spins at high speeds, effectively shredding materials into small fragments. The shredder ensures that the materials are cut into easily manageable and transportable pieces. The machine produces consistent output, ideal for recycling processes.

Low Maintenance Cost

The Single Shaft Shredder is designed with cost-effective maintenance in mind. The machine is equipped with a robust frame that supports the rotor and blades. The blades are crafted from high-quality materials capable of withstanding the pressures of shredding. The machine necessitates minimal maintenance, making it a cost-efficient choice for industrial applications.

High Efficiency

The Single Shaft Shredder is engineered for high efficiency. It is powered by a potent motor that drives the rotor. The motor is designed to operate at high speeds, guaranteeing that materials are shredded into small pieces. The machine is designed to handle substantial volumes of materials, making it suitable for industries with high throughput requirements.

Conclusion

Single Shaft Shredder machines are indispensable in industries dealing with waste materials. These machines are designed to produce high-quality output, require minimal maintenance, and operate with efficiency. Available in various sizes and designs, these machines allow industries to select the one that best fits their requirements. If you are in the market for a shredder machine, the Single Shaft Shredder is a worthy consideration.

Adapt the screen to your needs. The smaller the hole diameter, the finer the shredded material that is discharged. Screens can be exchanged flexibly and are bolted as standard.

Perfect cutting gap due to adjustable counter knives

Warranty

All recycling machines are accompanied by a 1-year limited warranty.

INQUIRIES

To obtain the latest prices and lead times, please send us a message using the form below.